What are the advantages of backhoe loaders?

Backhoe loader is a multifunctional engineering machine that combines the functions of an excavator and a loader. It is widely used in municipal construction, farms, road maintenance, small mines, pipeline laying and other scenarios. Its main advantages are as follows:

1. One machine with multiple uses and comprehensive functions

Front loading: used for shoveling soil, loading vehicles, and leveling the road surface;

Back-end excavation: can be used for trenching, pitting, slotting, etc.;

Optional accessories: such as breaker hammer, auger, compactor, etc. to expand more functions.

Advantages: Save equipment purchase costs and operating space, suitable for multi-task operations.

2. Flexible and adaptable to complex working conditions

Compact size, smaller than standard excavators, suitable for small spaces such as cities, farms, tunnels, etc.

It has the ability to travel on roads, does not rely on trailers, and is easy to move to the working location.

Advantages: strong adaptability, flexible operation, especially suitable for mobile operations.

3. Simple operation and short training cycle

The control system is user-friendly, with integrated cab control device and clear operation logic;

One driver can complete loading and excavation operations independently.

Advantages: Reduce labor costs and shorten training time.

4. Save equipment quantity and maintenance costs

Compared with purchasing a separate loader + excavator, a backhoe loader is more economical in terms of equipment purchase, maintenance, and parts replacement;

The maintenance cycle of a machine is shorter and more centralized, and operation and maintenance efficiency is higher.

Benefit: Reduced total cost of ownership (TCO).

5. Widely applicable construction scenarios

Widely used in: municipal pipeline excavation, building construction foundation, farm road maintenance, canal cleaning, etc.

It is particularly suitable for occasions where the amount of work is not large but the types of operations are diverse.

Advantages: Applicable to many industries, one of the main models in construction units.

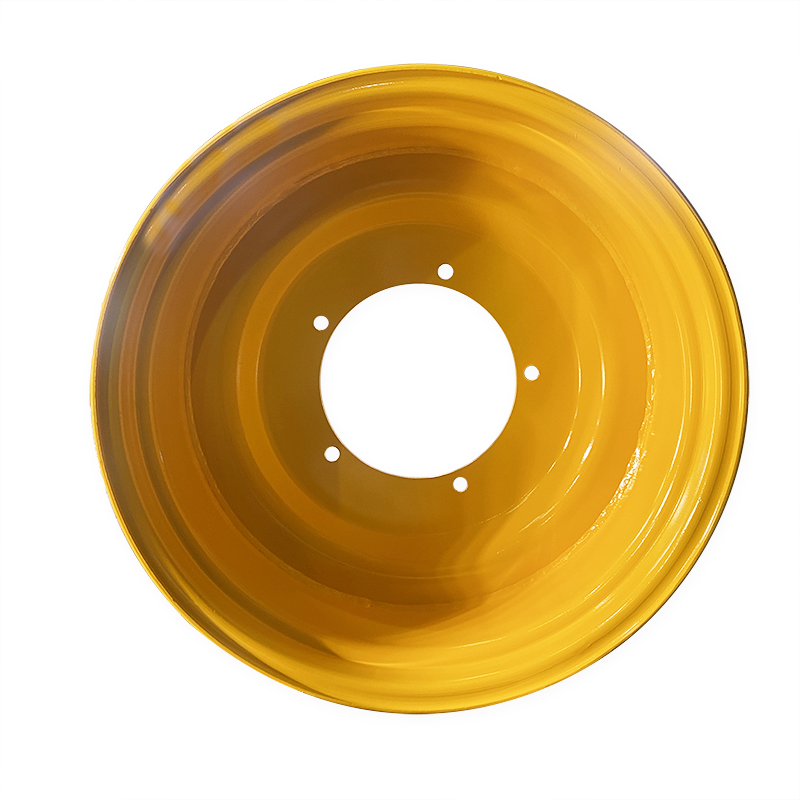

Backhoe loaders often work on complex terrains and are often under high load conditions. As a core operating accessory, the wheel rim plays a vital role in the safety, load-bearing capacity, driving stability and operating efficiency of the equipment.

Backhoe loaders often operate under heavy load conditions. The rims need to bear the weight of the entire machine and the material load, and high bending strength is required. In addition, the rims connect the tires and axles , and are the bridge between the tires and the transmission system, transmitting driving force, braking force and steering force. The closed structure ensures normal inflation and pressure maintenance of the tires to prevent air leakage or blowout. In an operating environment that often contains stones and potholes , the rims have the characteristics of high impact resistance and non-deformation . The appropriate rim width and structure are conducive to stable support of the tires and improve stability and traction during operation.

HYWG is China's No.1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, John Deere, and JCB .

We provide 15x28 rims for JCB's backhoe loaders.

15x28 rim is a kind of rim commonly used in industrial vehicles such as backhoe loaders .

"15": indicates that the width of the rim is 15 inches;

"28": means the diameter of the rim is 28 inches;

Large diameter and medium width, suitable for the rear wheels of medium and large equipment, enhancing ground adhesion and load-bearing capacity . Compatible with a variety of tire widths, with medium and high air pressure, it can maintain grip and buffer vibration .

Why should you choose 15x28 rims for backhoe loaders ?

The reason why 15x28 rims are chosen in backhoe loaders is mainly to meet the traction requirements, load-bearing capacity, ground adaptability and working stability of the rear wheels. This is a common specification for rear wheels, especially on medium-sized backhoe loaders.

Choosing 15x28 rims has the following advantages:

1. Matching large-size drive tires : 15x28 rims are often matched with rear tires with large tire widths and high tire diameters such as 16.9-28 and 18.4-28 to provide good traction and passability.

2. Enhance rear wheel traction : The rear wheel is responsible for the main drive. The combination of wider rims and large-diameter tires improves adhesion and is suitable for slippery sites such as soft soil and loose sand.

3. Strong load-bearing capacity : The rear wheels bear more loads from the whole machine counterweight and rear shovel operation. The 15-inch wide rim + thick tire provides sufficient support and is not easily deformed.

4. Ensure the stability of rear excavation operation : During rear excavation operation, the stability of the rear part of the whole machine is required to be high, and the combination of large rims + wide tires provides stronger ground support and anti-settling ability.

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: May-26-2025