combine harvester It is a multi-functional operating machine designed specifically for agricultural harvesting scenarios, used for integrated operations such as harvesting, threshing, cleaning, and loading of crops such as wheat, corn, and soybeans.

To enable combine harvesters to maintain stability, durability, and continuous operation in varied terrains, HYWG provides custom-developed and precision-manufactured high-quality agricultural rims, which contribute to efficient harvesting in farmland worldwide with strong load-bearing capacity and superior durability.

Harvesters will generate continuous and uneven loads when working at full capacity, in uneven terrain, and in soft, wet fields.

HYWG rims are made of high-strength steel , which has higher yield strength and better impact resistance . They can maintain excellent stability even when operating under full load for a long time , adapting to heavy agricultural conditions and ensuring that combine harvesters remain as stable as a rock in complex fields.

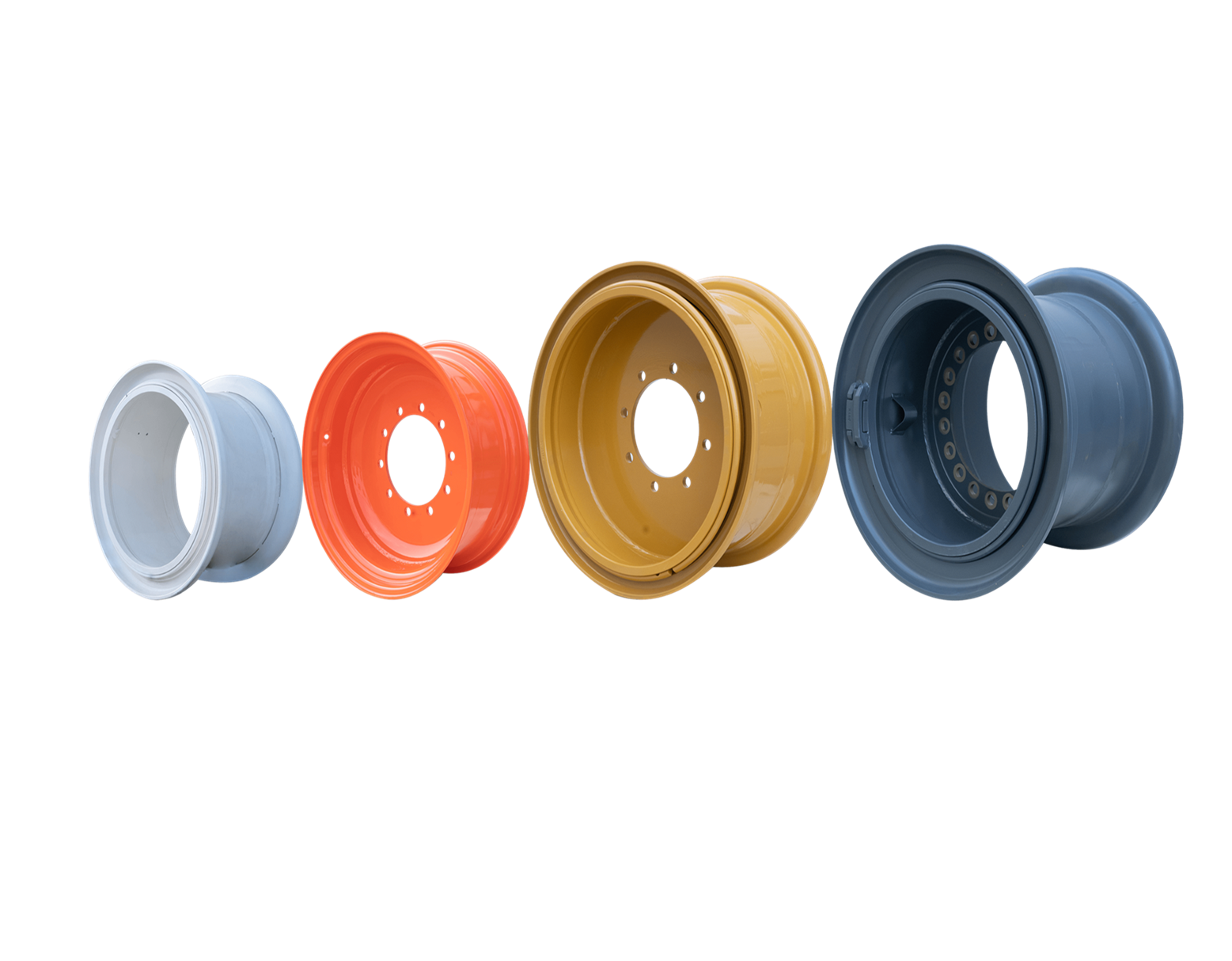

The 9.75×16.5 rim is the 1PC structure rim of TL Tire, which is commonly used in agricultural machinery such as combine harvesters and harvesters. We export agricultural rims to Europe and other international locations.

Combine harvesters are typically equipped with agricultural-specific tires and high-load-bearing agricultural rims with a wide base design to reduce soil compaction . Such rims must have extremely high load-bearing capacity and impact resistance , excellent welding strength , and adaptability to long-term wet and vibration conditions . This is the fundamental reason why HYWG can provide stable and highly durable rims for these types of harvesters.

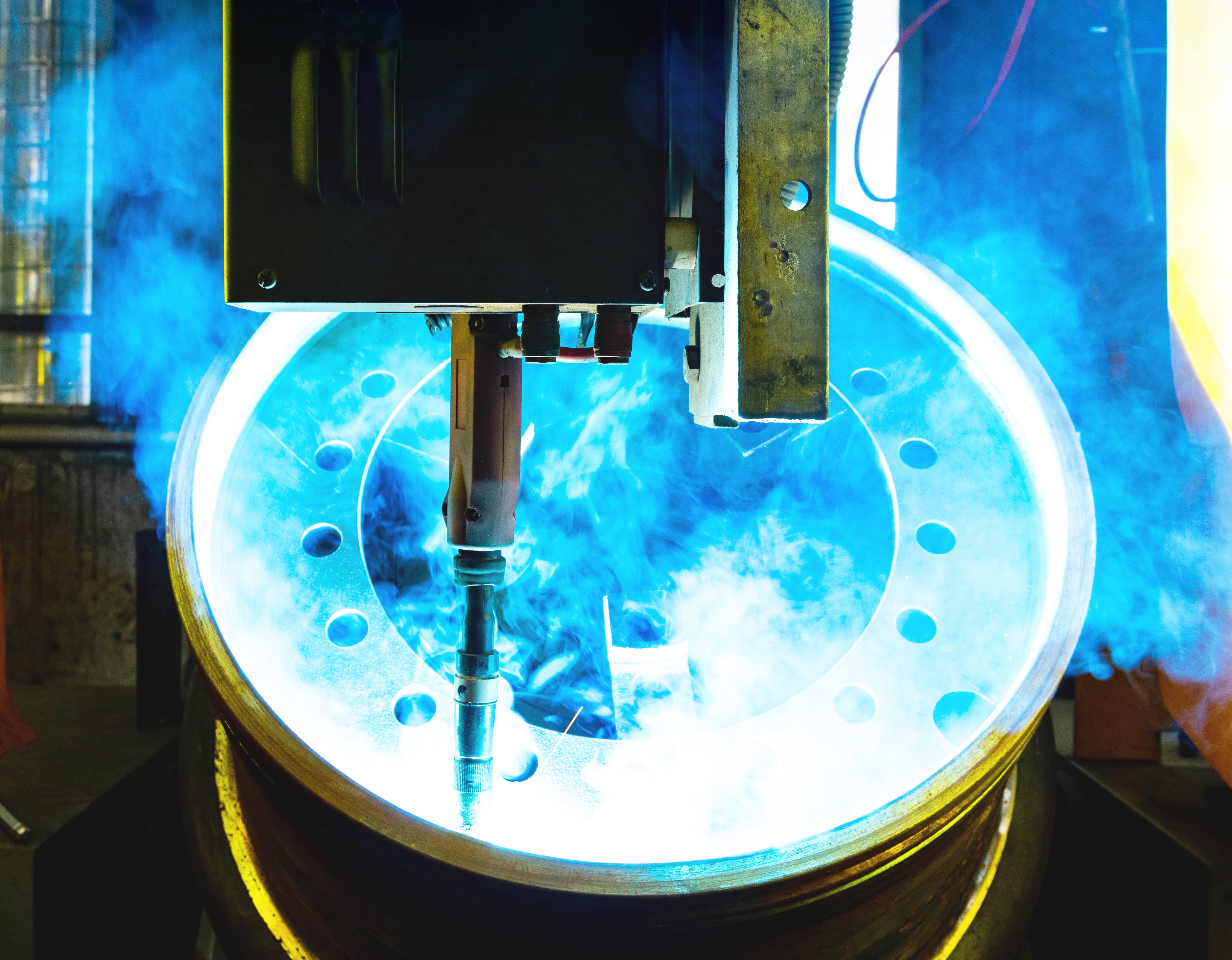

As one of the world's top three OTR wheel manufacturers, and one of the few companies in China capable of producing the entire industrial chain of wheel rims from steel to finished products , we independently produce rim profiles, making our products superior to ordinary standard wheel rims in terms of concentricity , fatigue resistance , welding strength , and service life .

From steel rolling, mold design, high-precision forming, automated welding to surface treatment and finished product inspection , this "one-stop" production model ensures that all products meet uniform high standards, truly realizing full-chain manufacturing and quality control of wheel rims.

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

5.Painting

6. Finished Product

Each wheel rim undergoes automated welding and rigorous non-destructive testing to ensure it does not crack or deform under long-term vibration and impact.

HYWG designs its products to match the tire specifications, load parameters, and body structure of combine harvesters, achieving precise tire fit , better bead protection , more balanced stress distribution , and better overall machine stability and passability , truly tailoring them to agricultural machinery.

Tests have shown that HYWG agricultural rims can operate continuously for 10+ hours . Even in uneven terrain and high-vibration environments , as well as complex soil conditions such as muddy, soft, and gravel roads, they can maintain stability and reliability in the face of high-load impacts under full load conditions . With stronger load-bearing capacity and greater durability, they bring higher efficiency to global agricultural production.

HYWG rims allow combine harvesters to maintain high uptime throughout the harvest season, reducing downtime and maintenance, and enabling efficient harvesting of every field.

With over two decades of dedicated experience, HYWG has served hundreds of OEMs worldwide, designing and manufacturing high-quality rims for a wide range of off-highway vehicles. It has become a long-term partner of globally renowned agricultural, engineering, and mining OEMs .

HYWG's products not only hold a significant market share in China but are also exported to more than ten mining-developed regions, including North America, Europe, Australia, and Russia. With leading manufacturing capabilities, rigorous quality control, and a global service system, we provide reliable wheel rim solutions for our customers. We are an original equipment manufacturer (OEM) wheel rim supplier in China for renowned brands such as Volvo, Caterpillar, Liebherr, and John Deere.

HYWG is committed to providing more reliable rim solutions for agricultural users worldwide.

We have extensive involvement in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: Dec-16-2025