In high-intensity operating environments such as port loading and unloading and yard transfers, heavy-duty forklifts constantly face challenges of high loads, frequent starts and stops, and complex road conditions. As a crucial load-bearing component connecting the tires to the entire vehicle, the structural strength and manufacturing quality of the wheel rim directly determine the safety, stability, and operational efficiency of the equipment.

The HYWG 11.25-25/2.0 rim is a professional solution tailored for high-load industrial equipment such as heavy-duty forklifts in ports.

The 11.25-25/2.0 rim is a 5PC structure rim for TL tires, commonly used in construction equipment. We are the original rim supplier for Volvo, Caterpillar, Liebherr, John Deere, and Doosan in China.

HYWG manufactures its own rim profiles using high-strength steel and optimized cross-sectional design, ensuring rim stability under full load and impact conditions and effectively dispersing stress concentration between the tire and rim.

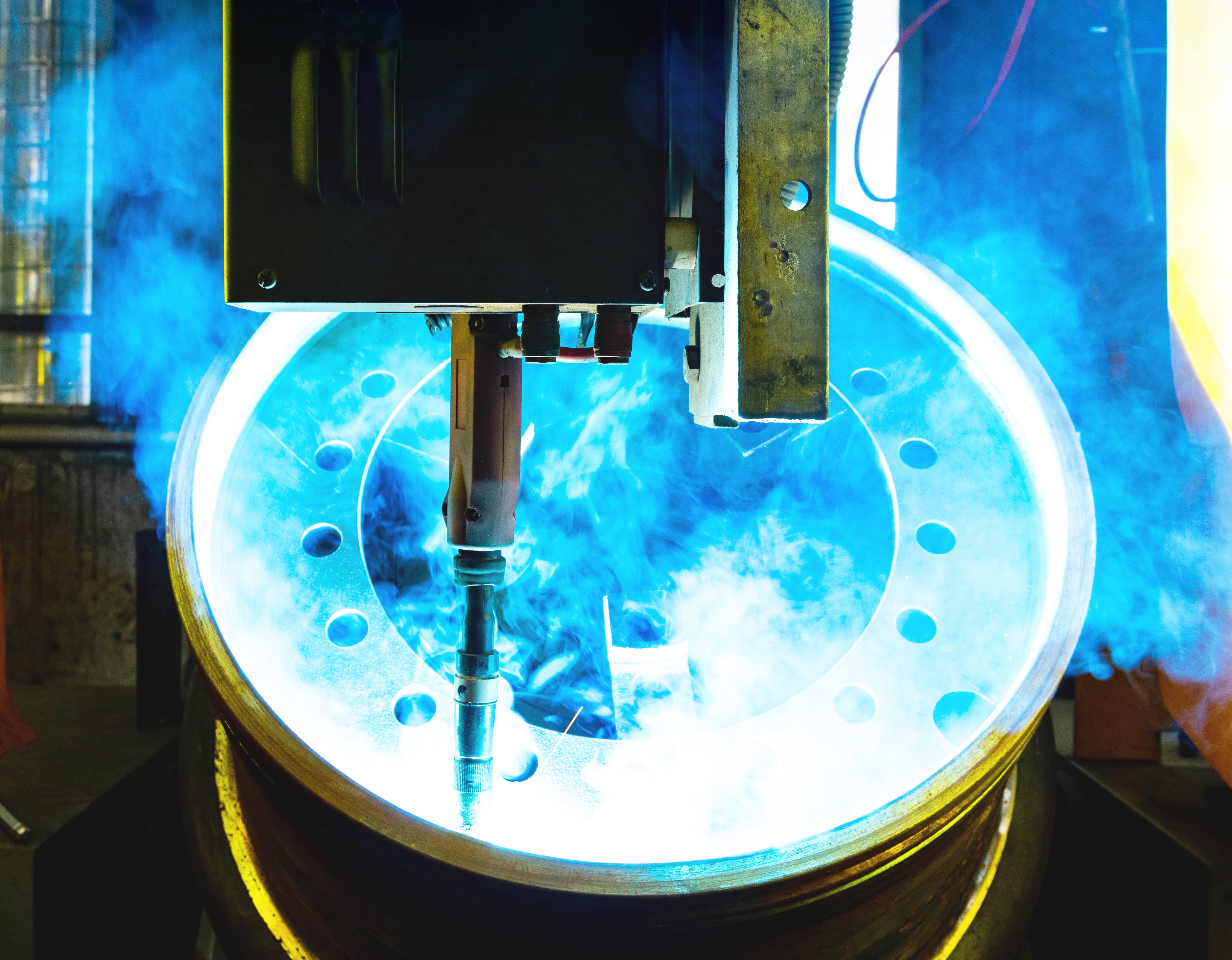

A "one-stop" production model has been established , from steel to finished wheel rims . From steel rolling, mold design, high-precision forming, automated welding to surface treatment and finished product inspection, it ensures that all products meet the same high standards. Each wheel rim remains stable and reliable under the most demanding working conditions , truly realizing the whole chain manufacturing and quality control of wheel rims .

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

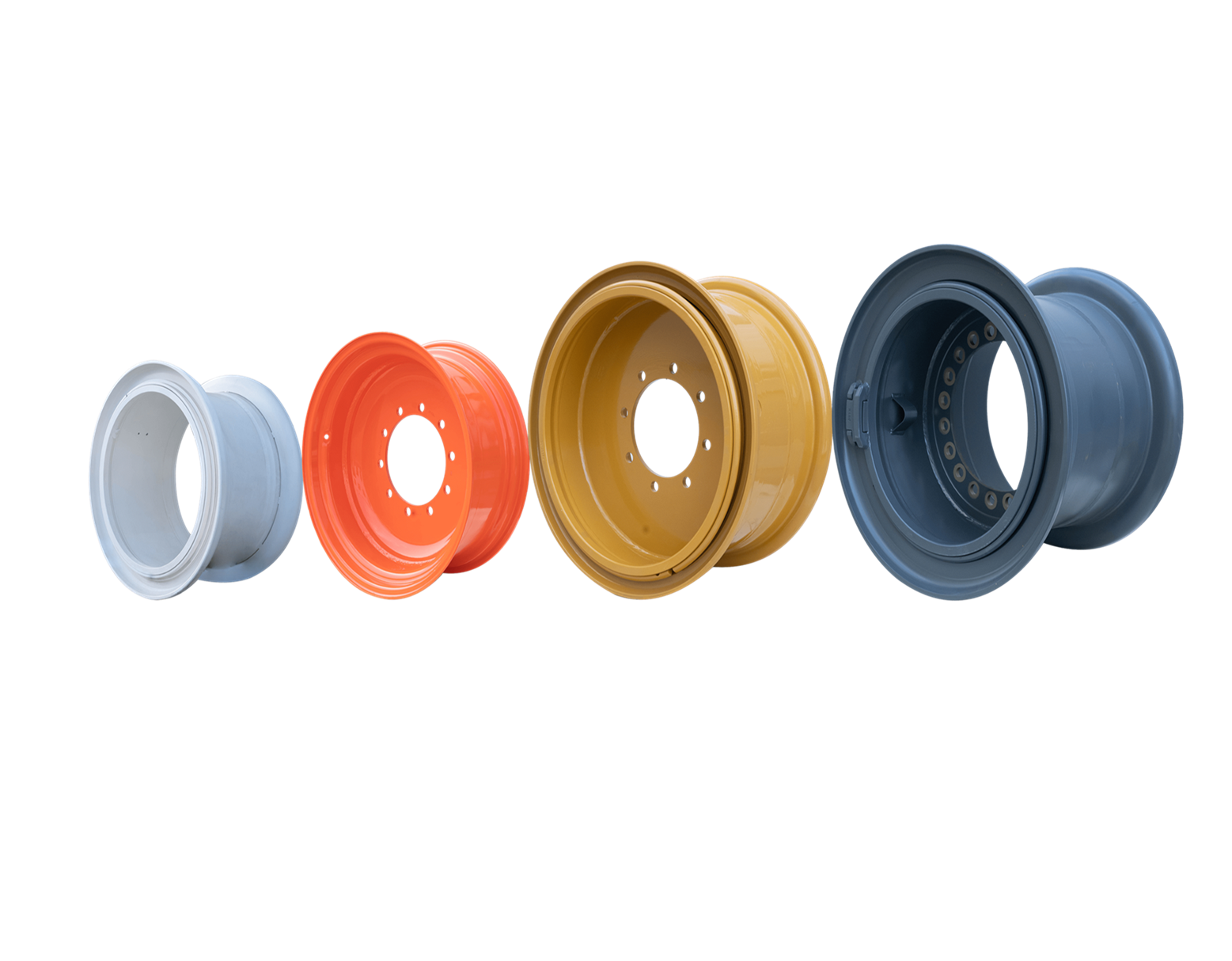

5.Painting

6. Finished Product

In response to the lateral forces, sharp turns, and frequent braking commonly encountered in port operations, HYWG incorporates a higher safety factor during the design phase to reduce the risk of rim deformation and fatigue damage.

HYWG boasts a research and development team comprised of senior engineers and technical experts, focusing on the research and application of innovative technologies. Through precise steel profile design and structural optimization, they enhance the overall strength of wheel rims under heavy-duty conditions . They also strictly control welding processes and dimensional tolerances to ensure stable fit between the wheel rims and 25-inch heavy-duty tires, reducing abnormal wear and meeting vehicle usage requirements .

In response to the typical port environment, such as salt spray, humidity, and dust, HYWG rims have undergone targeted enhancements in surface treatment and anti-corrosion processes, while also undergoing rigorous inspections of the rim appearance.

1. Check the rim surface for cracks , paying particular attention to the rim edge, weld seam, lock ring groove, and around bolt holes .

2. Are there any obvious deformations ? Are there any dents, bulges, out-of-roundness, or unevenness ?

3. Is there severe rust ?

4. Check if the coating is intact : Are there any peeling, flaking, bubbles, or other defects ?

Port forklifts often operate continuously for long periods, resulting in high downtime costs. A high-quality wheel rim is not only related to safety but also to overall operating costs . It can reduce unplanned downtime caused by wheel rim problems , extend the overall lifespan of the tires and wheel rims , and thus improve the overall stability and driving comfort of the vehicle .

Although small, the wheel rim is a key basic component for the stable operation of port equipment.

over two decades of experience in OTR and industrial rims , HYWG has provided stable and reliable rim solutions to customers in ports, mines, and construction machinery worldwide. Whether under high loads, strong impacts, long-term continuous operation, or complex terrain and harsh environments, HYWG rims have earned customer trust through their stable performance.

The 11.25-25/2.0 rim is a testament to HYWG's technical strength and manufacturing experience in heavy-duty applications, and also demonstrates our relentless pursuit of safety, quality and long-term value.

to more than ten countries, including North America, Europe, Australia, and Russia . With leading manufacturing capabilities, rigorous quality control, and a global service system, we provide customers with reliable wheel rim solutions. We are an original equipment manufacturer (OEM) wheel rim supplier in China for renowned brands such as Volvo, Caterpillar, Liebherr, and John Deere.

With its stable quality and excellent service, HYWG has gradually become a trusted partner for OTR users worldwide.

We have extensive involvement in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: Jan-04-2026