In modern road construction and mine grading operations, the VEEKMAS 160 motor grader is renowned for its superior dozing and grading performance . This mid-to-large motor grader faces demanding, high-intensity, high-wear conditions in daily operations, such as mining, road construction, and airport runway maintenance.

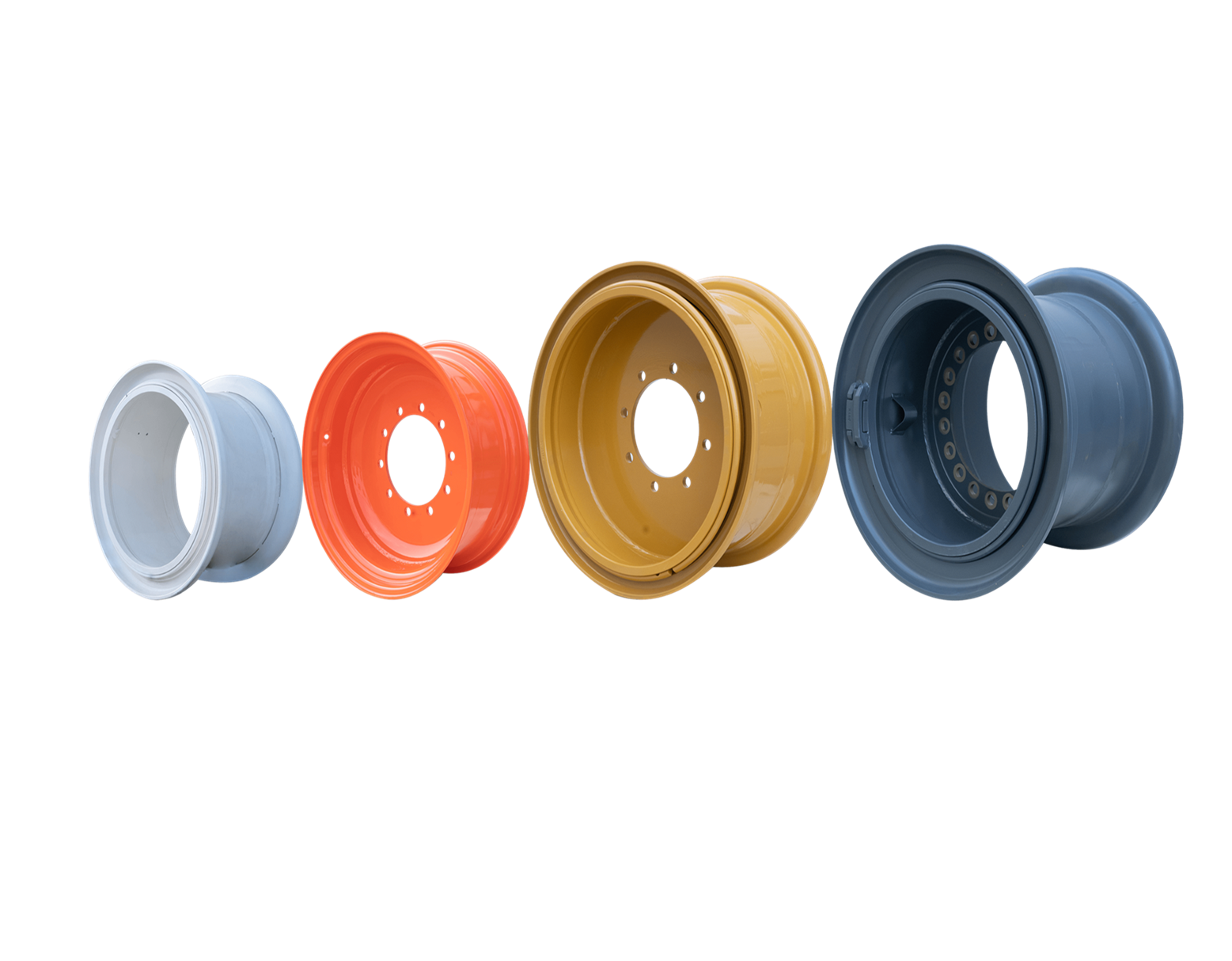

In order to match the stringent working conditions of this high-performance equipment, HYWG specially provides it with high-strength 14.00-25/1.5 rims to ensure the stability and durability of the entire machine in extreme operating environments.

The 14.00-25/1.5 rims produced by HYWG are made of high-quality, high-strength steel. Each set of rims undergoes rigorous load-bearing tests, non-destructive testing, and other rim inspection processes to ensure that the product quality meets international standards and can withstand the huge torque and vertical loads generated by graders when bulldozing and scraping .

The 3PC multi-piece structural design effectively improves the load-bearing capacity and impact resistance, enabling the grader to cope with the high impact loads on complex surfaces such as gravel, hard soil and unpaved roads.

This rim perfectly matches the VEEKMAS 160 tire, ensuring even tire pressure distribution and reducing uneven wear. The precise 1.5-inch flange width design ensures a tight fit between the tire and rim, ensuring a smooth ride while improving overall work efficiency and safety.

HYWG uses advanced electrophoretic coating and anti-corrosion treatment technology to give the rim excellent corrosion resistance, enabling long-term use in rain, snow, high humidity and salty environments, significantly extending the service life of the rim.

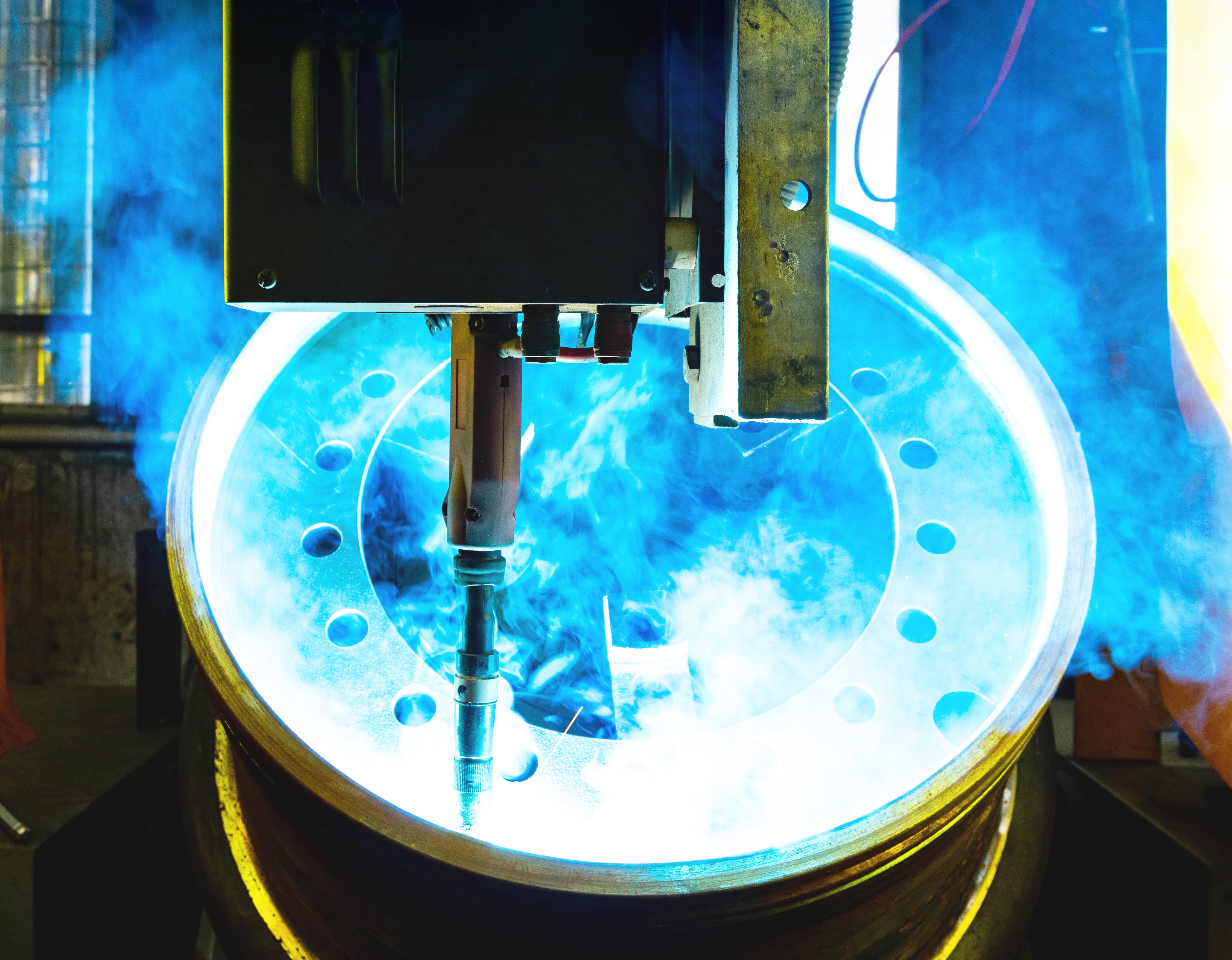

As one of the world's leading manufacturers of off-the-highway (OTR) rims, HYWG boasts a complete, integrated supply chain, encompassing comprehensive production processes from steel rolling, precision forming, automated welding, and surface coating. Leveraging advanced manufacturing processes and a modern testing system, HYWG rims remain at the forefront of the industry.

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

5.Painting

6. Finished Product

The VEEKMAS 160 motor grader excels in road construction, mine site preparation, snow clearing, and other applications. The addition of HYWG high-strength rims not only provides strong structural support but also ensures excellent reliability and economy even under long-term, high-load operation.

Since its establishment in 1996, HYWG has focused on the research, development, and production of steel rims and rim accessories. We have a strong position in the OTR rim market, and our rims meet internationally leading standards in strength, durability, and safety. We have a R&D team comprised of senior engineers and technical experts focused on the research and application of innovative technologies. We have established a comprehensive after-sales service system, providing timely and efficient technical support and after-sales maintenance to ensure a smooth customer experience.

We have established long-term cooperative relationships with many internationally renowned OEMs, and our products are exported to Europe, North America, Southeast Asia and other regions. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

We have extensive involvement in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: Sep-28-2025