In mines and heavy loading operations worldwide, the Caterpillar 988H has become a mainstay in many mining, quarry, and heavy material handling industries due to its powerful loading capacity, stable performance, and outstanding durability. To fully unleash the performance potential of this giant loader, HYWG custom-designed high-strength 28.00-33/3.5 rims, demonstrating exceptional reliability and safety in extreme environments of heavy loads, high impacts, and high wear.

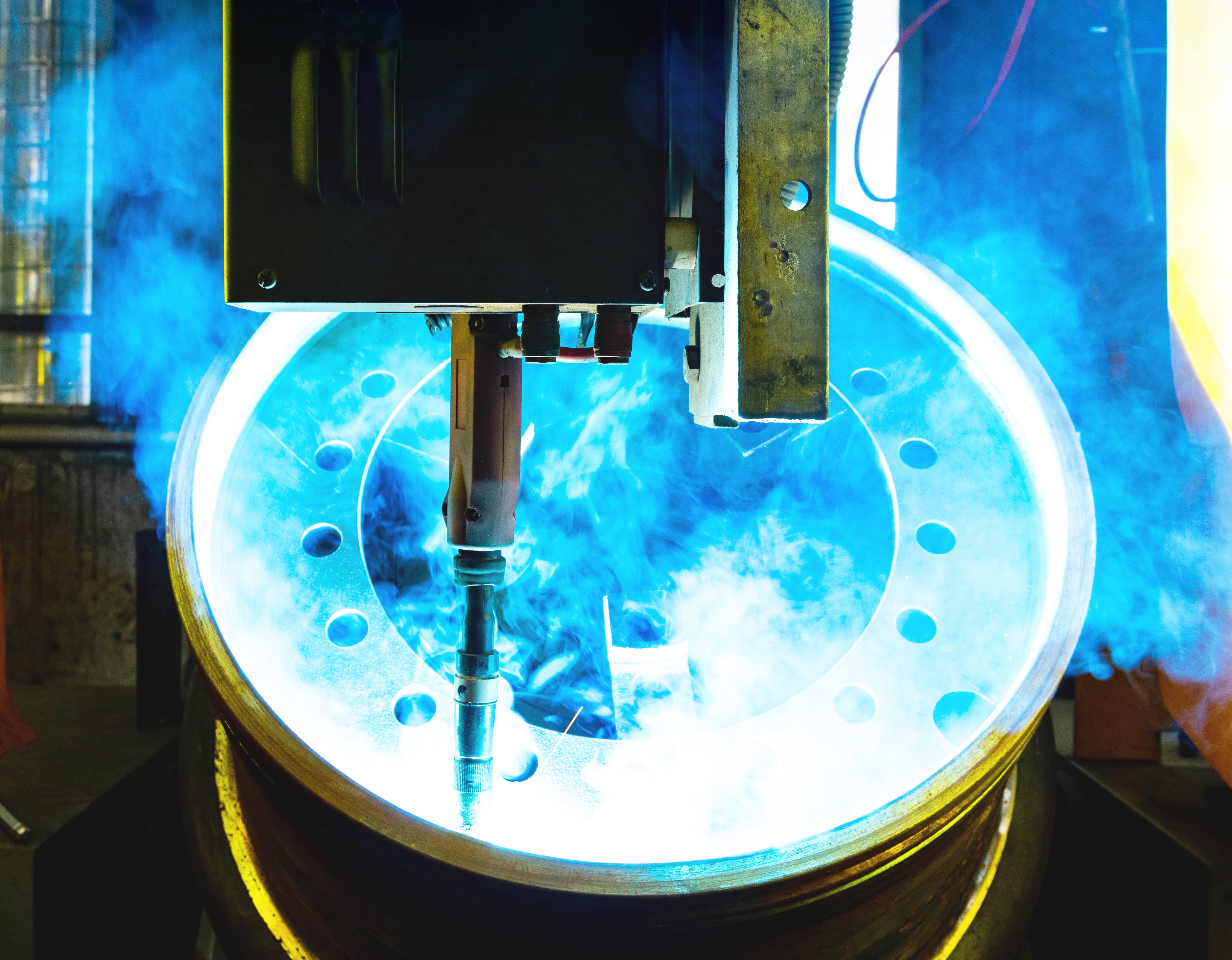

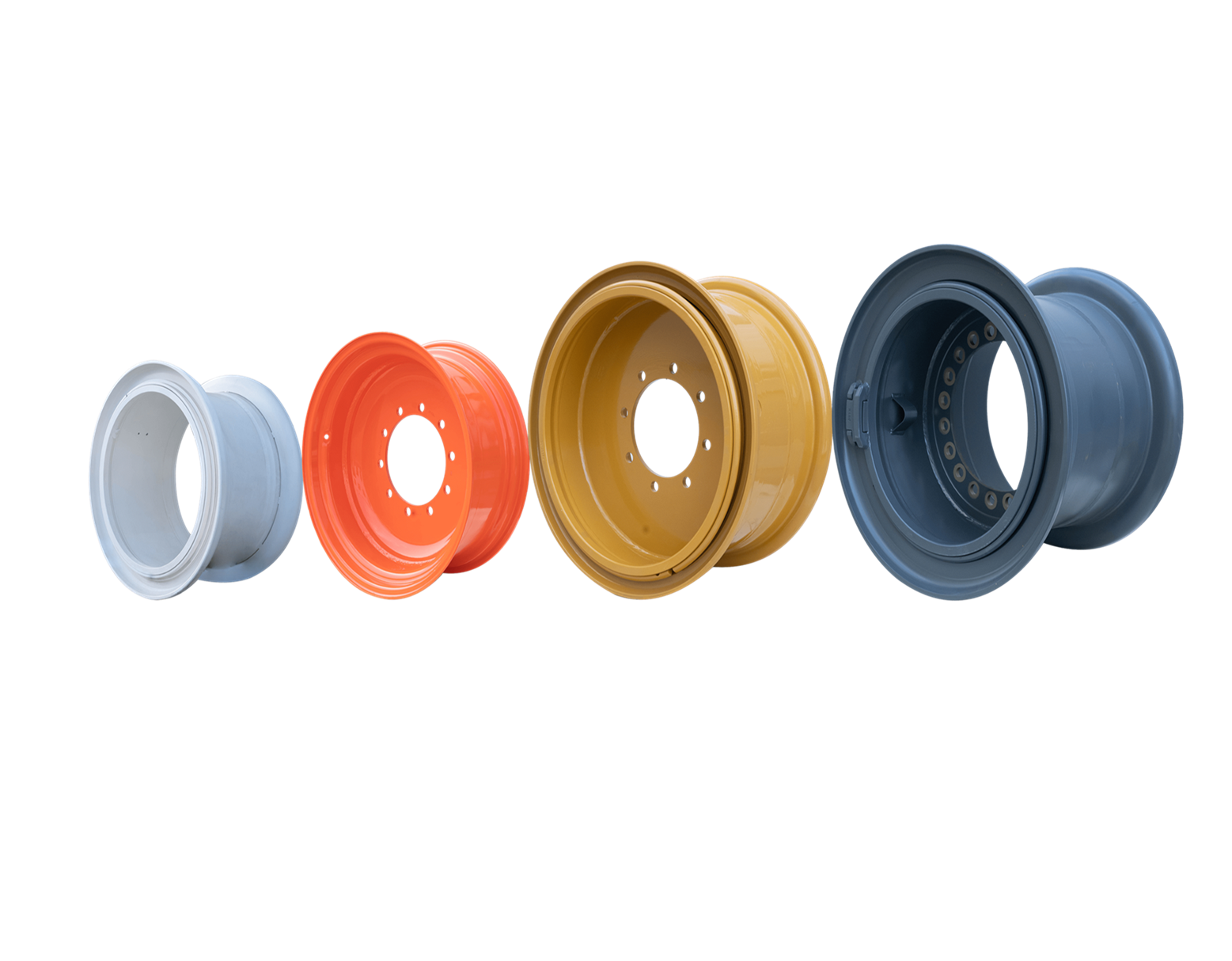

HYWG's 28.00-33/3.5 multi-piece 5PC rims, designed for CAT 988H tires, are specifically designed for large mining tires such as 35/65 R33. This structure is manufactured using precision rolling, automated welding, and high-strength heat treatment processes to ensure the rim's structural stability under high loads and impact conditions.

For the high-impact conditions of the CAT 988H, the HYWG rim features a thickened flange ring, reinforced side rings, and an optimized locking ring groove structure. This improves crack resistance by 30%, effectively resisting heavy-load impacts and stone crushing. A multi-layer anti-corrosion coating ensures stable performance even in high humidity, salt spray, and mud environments. Optimized rim welding stress distribution extends service life and reduces maintenance frequency. This design has demonstrated excellent performance in long-term mining field testing, significantly reducing the risk of rim fatigue, locking ring detachment, and weld cracking.

We possess a complete industrial chain, encompassing steel rolling, mold design, high-precision forming, automated welding, surface treatment, and finished product inspection. This "one-stop" production model ensures that all products meet uniformly high standards, truly achieving full-chain manufacturing and quality control for wheel rims.

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

5.Painting

6. Finished Product

Higher strength and better stability of the rims mean better tire air tightness and assembly precision; reduced risk of deformation and air leakage under high temperature conditions; reduced maintenance downtime and increased equipment uptime.

Practice has shown that, under the same operating conditions, HYWG rims can extend tire life by approximately 15–25% and effectively reduce rim replacement cycles, significantly improving the overall economic efficiency of the machine.

With over two decades of experience, HYWG has served hundreds of OEMs worldwide . We have long been designing and manufacturing high-quality rims for various off-highway vehicles. Our R&D team, comprised of senior engineers and technical experts, focuses on the research and application of innovative technologies, maintaining a leading position in the industry. We have established a comprehensive after-sales service system, providing timely and efficient technical support and maintenance. Every step of the rim manufacturing process strictly adheres to high-standard quality inspection procedures, ensuring that every rim meets international quality standards and customer requirements.

HYWG is a leading global OTR rim manufacturer and an original equipment manufacturer (OEM) rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

We have extensive involvement in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: Nov-11-2025