FOREMOST swamp excavators, designed for operation in extreme terrains such as wetlands, swamps, and tidal flats, are widely used in oil fields, environmental remediation, and infrastructure projects due to their powerful mobility and stable performance. However, these machines operate in complex environments with high humidity and low traction for extended periods, placing extremely stringent demands on the performance of their tires and rims.

wheels for industrial vehicles and construction machinery in China , HYWG successfully provided customized high-strength solid tires and heavy-duty rim systems for FOREMOST swamp excavators, effectively ensuring the stability and reliability of the equipment under complex working conditions.

Solid tires are the preferred choice for heavy-duty construction machinery operating in extreme environments where zero downtime is required. HYWG's solid tire and rim solutions for FOREMOST vehicles deliver revolutionary reliability.

Solid tire construction eliminates the possibility of blowouts and leaks , providing permanent puncture resistance. Whether facing gravel, sharp metal, or hardwood stakes, it ensures continuous operation of the vehicle in deep swamps or at the exploration front, greatly improving work efficiency.

Our solid tires are designed for superior wear resistance and anti-aging properties, with a lifespan far exceeding that of pneumatic tires. This significantly reduces maintenance costs and replacement frequency in remote areas , resulting in an exceptionally long service life .

The tire structure is optimized to withstand the high ground pressure of the equipment on soft ground, ensuring that the swamp excavator has more stable lateral support and stronger compressive strength under extreme working conditions, perfectly matching the load-bearing requirements of the FOREMOST swamp excavator and ensuring the equipment is accurate and stable on complex terrain.

Solid tires require rims with higher strength and a more precise fit. HYWG's rim technology perfectly meets this challenge .

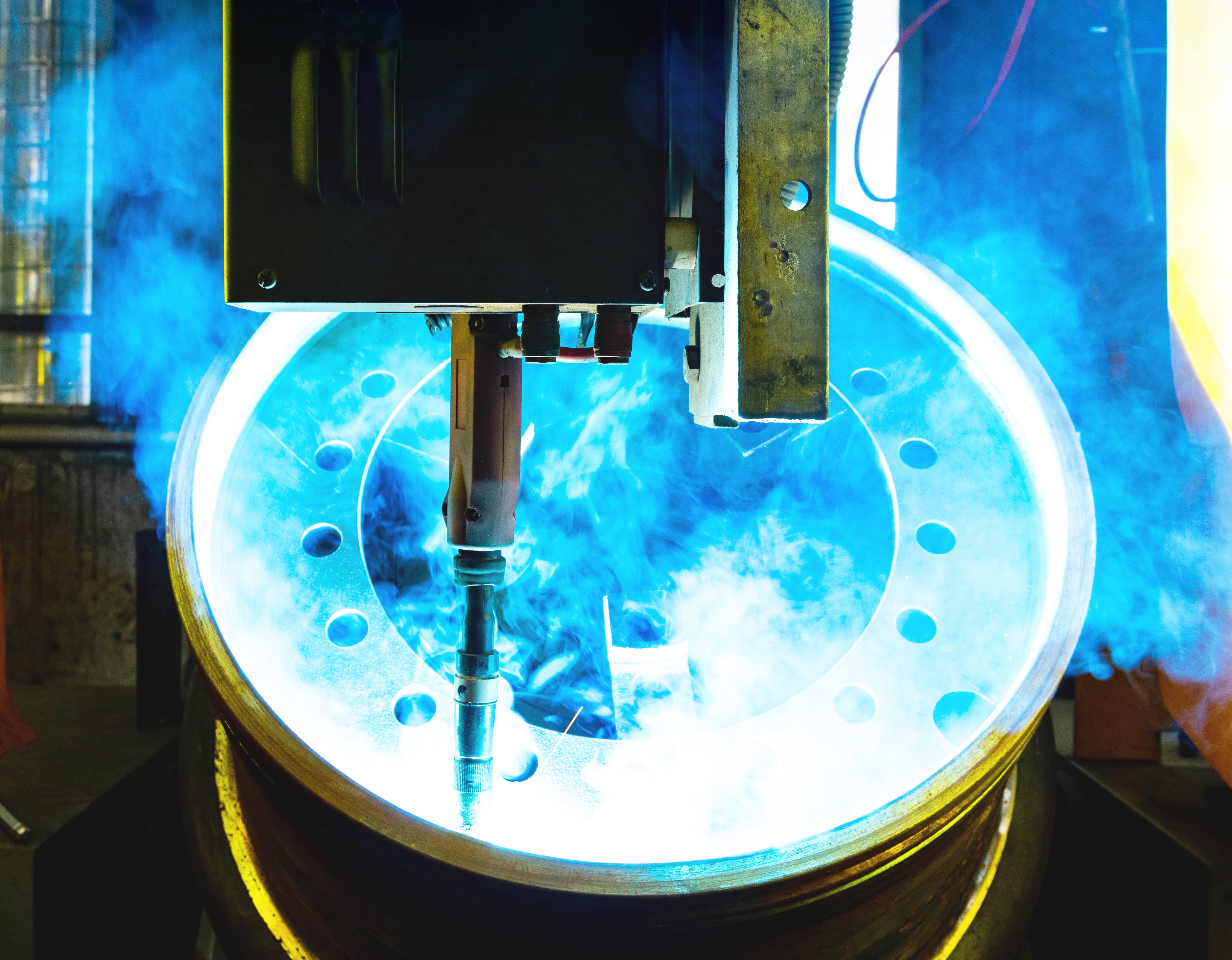

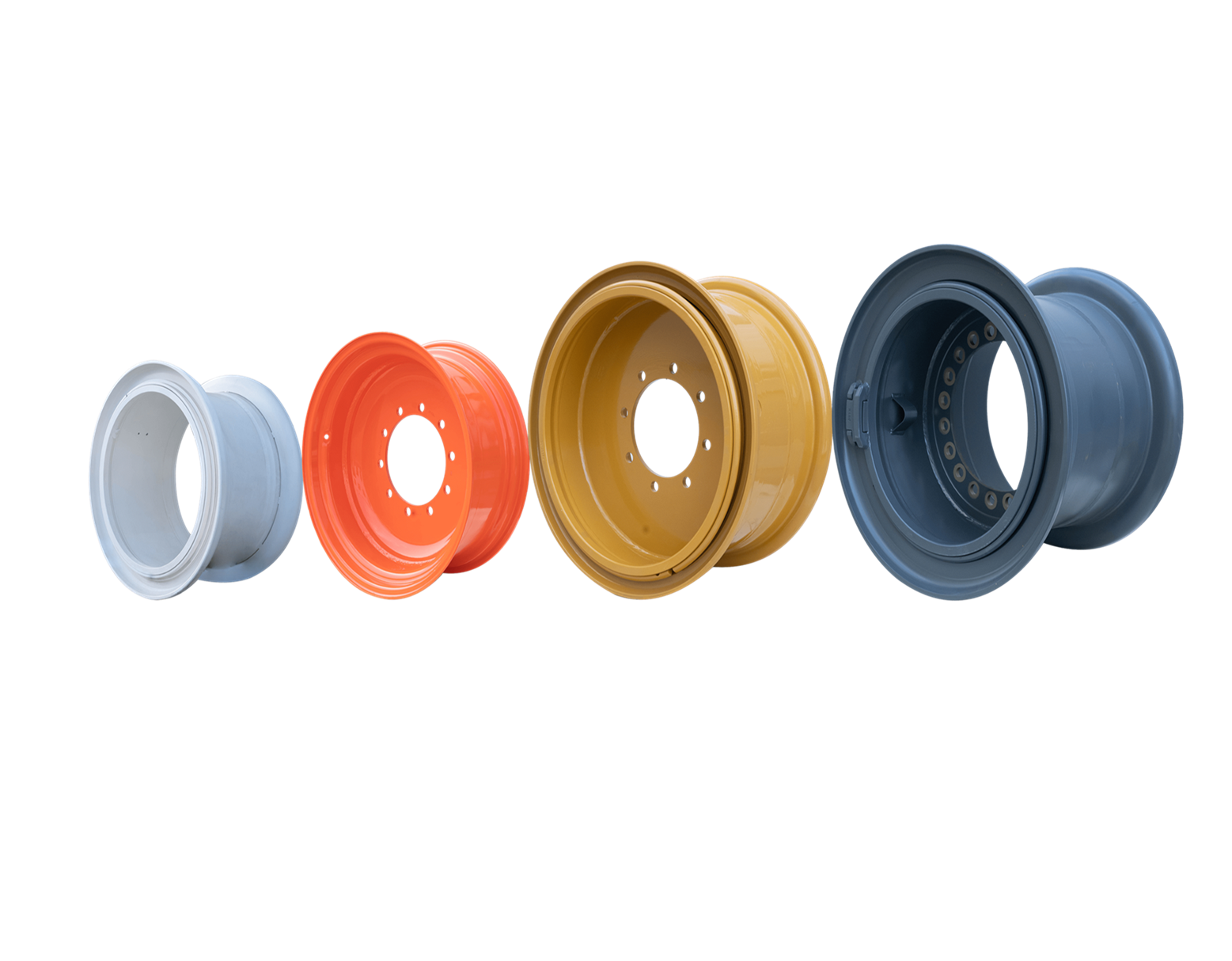

Our custom-designed rims are specifically tailored for solid tires , made from high-quality alloy steel and undergoing multiple welding and heat treatment processes to ensure excellent impact and deformation resistance , sufficient to withstand the higher stress concentrations associated with solid tires. For FOREMOST vehicles that are frequently exposed to corrosive swamp or polar environments, the rim surface undergoes a dual treatment of electrophoretic primer and powder coating, effectively resisting moisture and chemical corrosion in swampy environments.

The rims feature a special profile and locking structure that closely matches the solid tire structure, ensuring stable assembly, balanced operation, and effectively reducing the risk of rim loosening or slippage.

With advanced manufacturing processes and stringent quality control, HYWG rims not only perfectly match the special operating requirements of FOREMOST swamp excavators, but also enhance the vehicle's stability, load-bearing capacity, and durability, making every operation safer and more efficient.

With over two decades of experience, HYWG has served hundreds of OEMs worldwide and is an original equipment manufacturer (OEM) rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

We possess a complete industrial chain, encompassing steel rolling, mold design, high-precision forming, automated welding, surface treatment, and finished product inspection. This "one-stop" production model ensures that all products meet uniformly high standards , truly achieving full-chain manufacturing and quality control for wheel rims.

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

5.Painting

6. Finished Product

We have a long history of designing and manufacturing high-quality wheel rims suitable for various off-highway vehicles. Our R&D team, comprised of senior engineers and technical experts, focuses on the research and application of innovative technologies, maintaining a leading position in the industry. We have established a comprehensive after-sales service system, providing timely and efficient technical support and maintenance. Every step of the wheel rim manufacturing process strictly adheres to high-standard quality inspection procedures, ensuring that every wheel rim meets international quality standards and customer requirements.

We have extensive involvement in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: Nov-03-2025