CAT 982M is a large wheel loader launched by Caterpillar. It belongs to the M series high-performance model and is designed for high-intensity scenarios such as heavy-load loading and unloading, high-yield stockpiling, mine stripping and material yard loading. This model combines excellent power performance, fuel efficiency, driving comfort and intelligent control system, and is one of the core representatives of Caterpillar's large loaders.

3.jpg)

It is well-known for its powerful performance, excellent efficiency and high reliability. It is suitable for a variety of heavy material handling and loading tasks, and performs well in mines, quarries, large construction sites and port operations. It is very suitable for mines, quarries and other heavy-duty application environments. It has the following core advantages:

1. Strong power, suitable for heavy load and efficient loading

Equipped with Cat C13 engine, the power output is up to 403 horsepower; with large-capacity bucket, it can efficiently load various density materials (such as crushed stone, iron ore, coal, slag, etc.); it supports continuous stacking, loading and stripping operations with short cycle time. Suitable for continuous operation environments such as mining areas, material yards, ports, etc.

2. High fuel efficiency, lower operating costs

Cat M series has a unique intelligent load-sensing hydraulic system (load-sensing hydraulics); automatic matching of power and hydraulics to improve fuel utilization; equipped with ECO energy-saving mode + automatic idle shutdown function to save idling fuel consumption. Fuel savings can be up to 10~15% compared with previous models

3. Heavy-duty structural design, strong and durable

The whole vehicle adopts high-strength steel frame structure, heavy-duty rear axle, and reinforced boom; equipped with heavy-duty rims (25.00-25/3.5) and high-grade tires (L4/L5); suitable for scenes with highly abrasive materials such as gravel, iron ore, and slag. High attendance rate, long service life, and strong impact resistance

4. Intelligent control and excellent driving experience

Electric single-lever (EH) control system + automatic leveling/lift limit function; sealed cab equipped with air conditioning, suspension seat, shock absorption system, wide field of vision; standard Cat Product Link™ and VisionLink™ systems, support remote monitoring and maintenance reminders. More precise operation, suitable for high-frequency operations and multi-shift operation

5. Security and easy maintenance

Three-point access structure, rear-view camera, automatic brake system; centralized arrangement of filter element, battery, hydraulic oil port for easy ground maintenance; optional tire pressure monitoring (TPMS) and automatic lubrication system are supported. Reduce accident risks and maintenance downtime

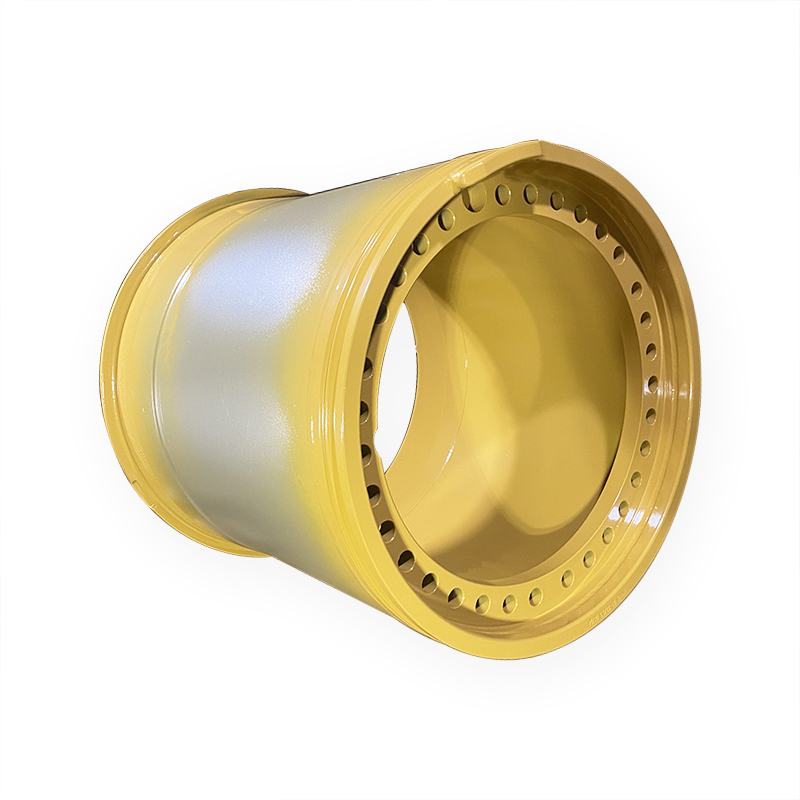

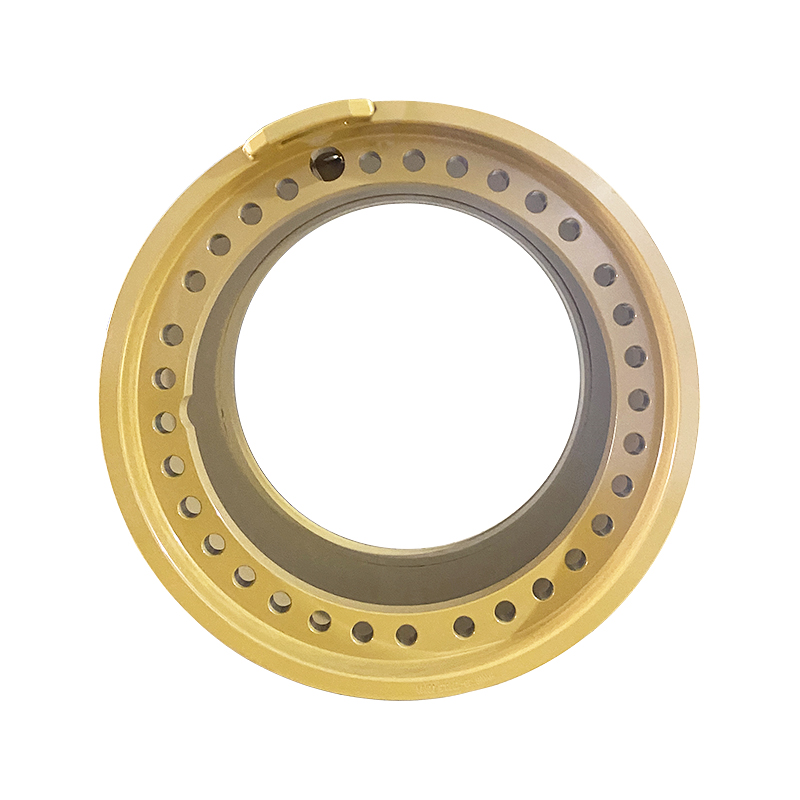

the harsh working environment of the CAT 982M wheel loader and its own high load, high frequency, and high torque operating characteristics, the selection of rims must take into account the load-bearing capacity, impact resistance, tire matching, and maintenance convenience. For this reason, we developed and produced 27.00-29/3.5 5PC rims.

The 27.00-29/3.5 5PC rim is a heavy-duty engineering rim specially used for super-large wheel loaders or rigid mining trucks. The tires that are suitable are mostly 33.25R29 or 33.25-29. It has the characteristics of ultra-high load-bearing capacity, strong impact resistance, split structure, and convenient maintenance. It is widely used in harsh working environments such as mines, ports, and stone factories.

The rim has a strong load-bearing capacity . With the 33.25R29 extra-large tire, the single wheel can bear more than 15~20 tons, meeting the heavy-duty operation requirements of loaders or rigid trucks over 40 tons. Suitable for: mine stripping, high-density ore shoveling, and large-scale loading operations .

3.5-inch thickened flange, strong structure , with higher deformation resistance; can effectively resist the tire internal pressure, impact force and lateral tearing force during high-frequency shoveling. Excellent impact resistance, longer rim life

Five-piece structure design , high maintenance efficiency . Easy to disassemble and install: tires can be quickly replaced on site without the need for special hydraulic disassembly and installation equipment; split structure reduces the risk of damage during loading and unloading . Commonly used in mining areas with high loads and frequent tire wear. Reduce downtime and improve attendance rate

What are the advantages of using 27.00-29/3.5 rims on CAT 982M wheel loader ?

CAT 982M wheel loader uses 27.00-29/3.5 specification rims , which are mainly reflected in enhanced load-bearing performance, stronger impact resistance, and better adaptability to extreme working conditions. It is suitable for higher strength, larger loads or special customized scenarios.

Mainly reflected in the following advantages:

1. Improve the load-bearing capacity of the whole machine to adapt to heavy-duty tasks

The matching 33.25R29 tire can withstand a higher single tire load (15-20 tons); meet the higher ground support requirements of the CAT 982M when fully loaded with high-density materials (such as ore and steel slag); reduce tire crushing and deformation, and improve stability. Suitable for high-frequency loading and high-density material stacking conditions

2. Thicker flange (3.5 inches) and more impact-resistant structure

The wider and thicker rim flange is less likely to deform under high lateral force and tire blowout impact; it has a stronger ability to absorb the instantaneous impact when shoveling large stones, iron ore, and steel slag. It greatly reduces the rim failure rate such as blowout, open welding, and cracks.

3. Improve vehicle stability and grip

The wider tire contact area makes the vehicle more stable when operating on soft ground, high slopes, gravel or slippery ground; it improves the anti-skid ability and front-end anti-lifting ability when shoveling. It improves safety and work efficiency and adapts to harsh terrain

4. Support heavy-duty cut-resistant tires to extend service life

Can be used with L5 grade high wear-resistant and cut-resistant tires; reduce tire bursts, shoulder damage, and uneven wear, and increase tire life by more than 20%. Reduce tire replacement frequency and control operating costs

5. Compatible with five-piece structure, easy maintenance

The split design supports quick tire removal and installation, reduces on-site maintenance time, and is suitable for mining areas or ports with high attendance requirements. It is especially suitable for multi-shift continuous operation units.

HYWG is China's No.1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards .

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing . We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. You can send me the rim size you need, tell me your needs and concerns, and we will have a professional technical team to help you answer and realize your ideas.

Our products are of world-class quality.

Post time: Sep-05-2025