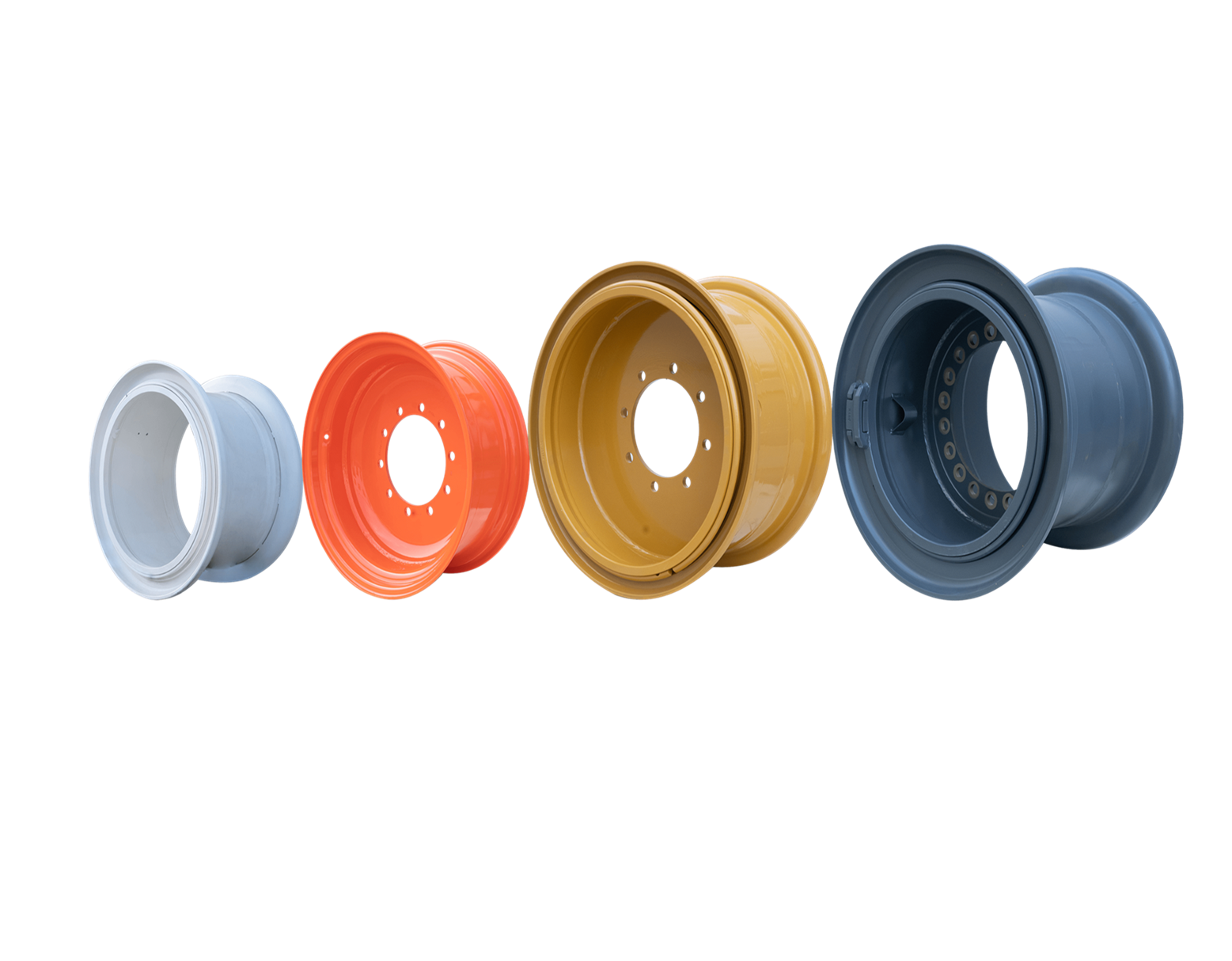

Heavy-duty wheels are wheel systems designed specifically for vehicles operating under high loads, high strength, and harsh environments. They are typically used in mining trucks, loaders, bulldozers, tractors, port tractors, and construction machinery. Compared to ordinary automotive wheels, they offer higher load capacity, impact resistance, and durability.

Heavy-duty wheels are typically made of high-strength steel and heat-treated to increase hardness and fatigue resistance. Unlike the one-piece construction common on passenger cars, heavy-duty wheels often adopt a multi-piece design, such as 3PC, 5PC, or split types. These components include the rim base, flange, lock ring, retaining ring, and other components. This facilitates the installation of large tires and improves maintenance convenience.

The rim is typically thickened , with the flange and lock ring areas thickened or reinforced to withstand the impact and loads of extreme operating conditions. The surface is treated with a dual-layer electrophoresis and powder coating process for excellent rust and wear resistance, ensuring long-term use in hot, humid, salty, or muddy environments.

These rims have exceptional load-bearing capacity , capable of withstanding single-wheel loads ranging from several to tens of tons, making them suitable for heavy-duty equipment such as mining trucks and loaders. On rough or uneven terrain, the wheels absorb impacts, preventing rim cracks and tire derailment.

Heavy-duty wheels are essential components for any equipment that needs to move or support large loads and maintain stability and reliability in harsh working environments.

As a leading rim and wheel manufacturer in China, HYWG specializes in providing high-strength, heavy-duty wheel solutions for mining machinery, construction equipment, agricultural vehicles, and port equipment. Leveraging its superior steelmaking expertise and international quality management system, HYWG has become a long-term partner of numerous renowned global OEMs.

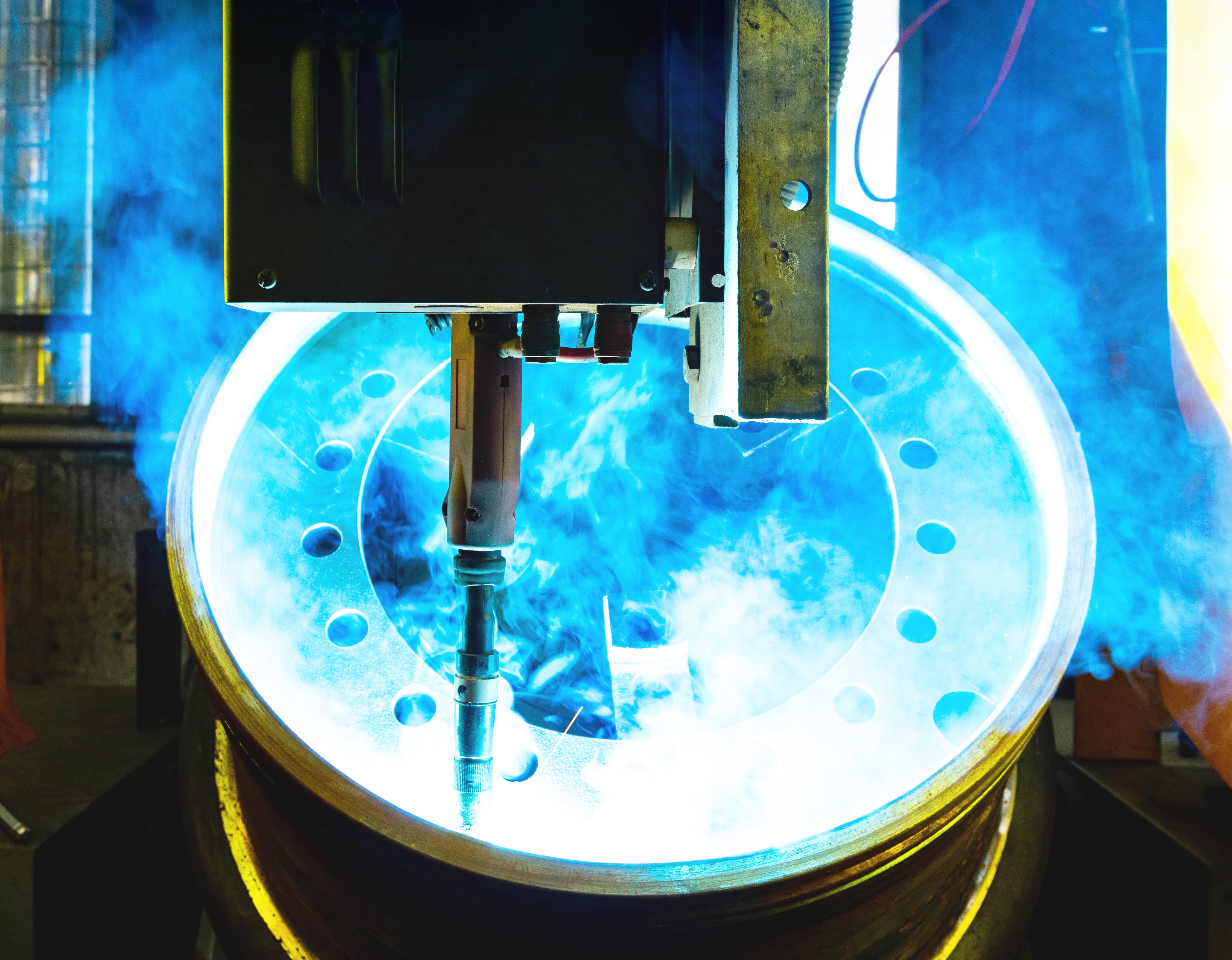

HYWG heavy-duty wheels are designed for high loads and harsh environments. Each wheel is made of high-strength steel . The company owns a complete supply chain, from steel rolling, mold design, high-precision forming, automated welding, surface treatment, and finished product inspection. This allows for independent control of the entire process, ensuring that each wheel rim meets international standards for strength, precision, and durability.

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

5.Painting

6. Finished Product

Each HYWG heavy-duty wheel undergoes a full inspection and simulated load test before leaving the factory to ensure stable performance under extreme temperature differences, heavy loads and high vibration conditions.

The factory is ISO 9001 certified and has earned recognition from renowned brands such as CAT, Volvo, and John Deere through over two decades of development . HYWG's superior quality and stable supply have enabled it to serve not only the Chinese market but also export its products to Europe, North America, Southeast Asia , and other regions . HYWG has been selected as a long-term supplier by numerous global construction machinery manufacturers. Our products are used in key applications such as mining, construction, farms, and ports, providing solid support for global equipment.

From raw steel to finished wheels, from design to performance, HYWG consistently adheres to the philosophy of "quality first, strength supreme." In the future, we will continue to innovate, providing global customers with safer, more efficient, and more reliable heavy-duty wheels, helping to advance global engineering equipment to higher standards.

HYWG——Make every device more powerful.

We have extensive involvement in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: Nov-03-2025

9.jpg)