Construction machinery tires are key components that enable construction machinery to work safely and efficiently in "off-road, heavy-load, and harsh working conditions".

It is not an ordinary tire that "runs fast", but a comprehensive system that combines load-bearing, traction, stability and safety.

In mining, construction sites, ports, and underground operating environments, the real challenge lies not in individual tires or rims, but in a complete "wheel system".

HYWG believes that the safety and efficiency of construction machinery begins with the correct matching of rims and tires.

Construction machinery tires are responsible for "load bearing and grounding" . Their core task is to bear the load of the whole machine and the work load , convert the engine power into traction , adapt to off-road surfaces such as gravel, mud and ore , absorb impact and protect the whole machine structure .

Under such complex and harsh working conditions, tires need to have the following characteristics: thick carcass , high grade , wide tread , deep tread pattern , cut resistance, impact resistance, and high temperature resistance .

, a tire can only perform at half its potential if it is properly, securely, and safely mounted on the rim.

The wheel rim of construction machinery is the key to determining "safety and upper limit" . If the tire is responsible for "contact with the ground", then the wheel rim is responsible for "supporting everything".

The core components of HYWG engineering machinery wheel rims include: bearing the full load of the tire and the entire machine , ensuring the correct positioning of the tire bead, preventing bead slippage , resisting impact loads and long-term fatigue , and ensuring the safe locking of multi-piece structures under high pressure .

On heavy-duty equipment such as mining trucks and loaders , the consequences of rim failure are often more serious than those of tire failure , and the safety margin must be higher than the "theoretical calculation value" .

As one of the world's top three OTR heavy-duty wheel rim manufacturers, HYWG has accumulated over two decades of experience in the production and R&D of wheel rims for heavy-duty vehicles such as mining vehicles and construction machinery vehicles. With a comprehensive after-sales service system , HYWG can provide timely and efficient technical support and after-sales maintenance .

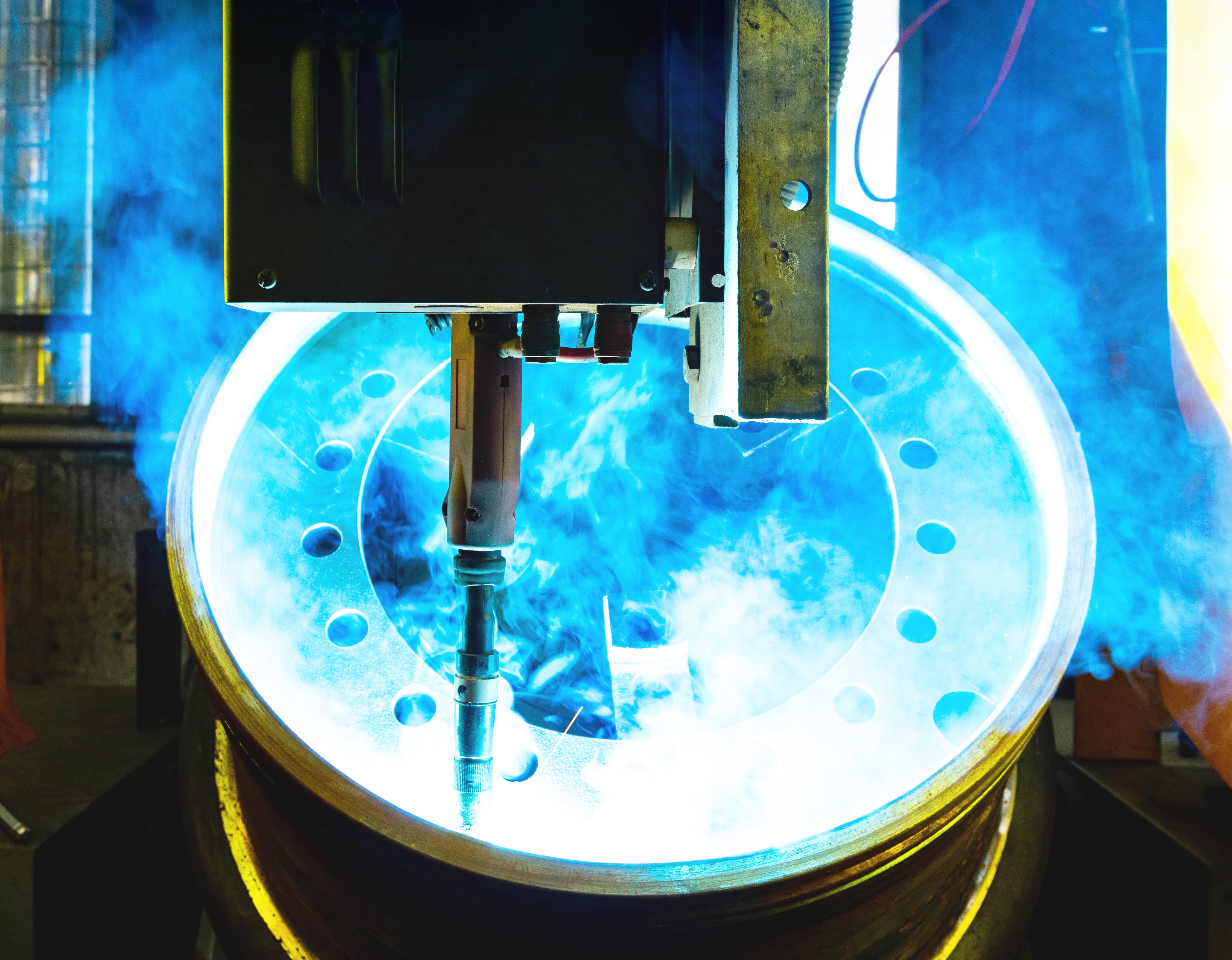

HYWG possesses the capability to independently produce steel profiles for wheel rims , marking a watershed moment in high-end manufacturing capabilities within the OTR wheel rim sector. The advantage it brings goes far beyond simply "making its own materials"; it determines the safety ceiling, consistency, and long-term reliability of the wheel rims from the very beginning.

The safety and lifespan of OTR rims are determined from the source of materials. This ensures that the product surpasses ordinary standard rims in concentricity , fatigue resistance , weld strength , and service life . High-strength, high-quality steel guarantees excellent fatigue and impact resistance .

It possesses a complete industrial chain production from steel to finished wheel rims , including steel rolling, mold design, high-precision forming, automated welding, surface treatment, and finished product inspection . This "one-stop" production model ensures that all products meet uniform high standards, truly realizing full-chain manufacturing and quality control of wheel rims.

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

5.Painting

6. Finished Product

When providing rims for mainstream loaders, mining trucks, and forklifts, HYWG always prioritizes system stability and safety margins in its design.

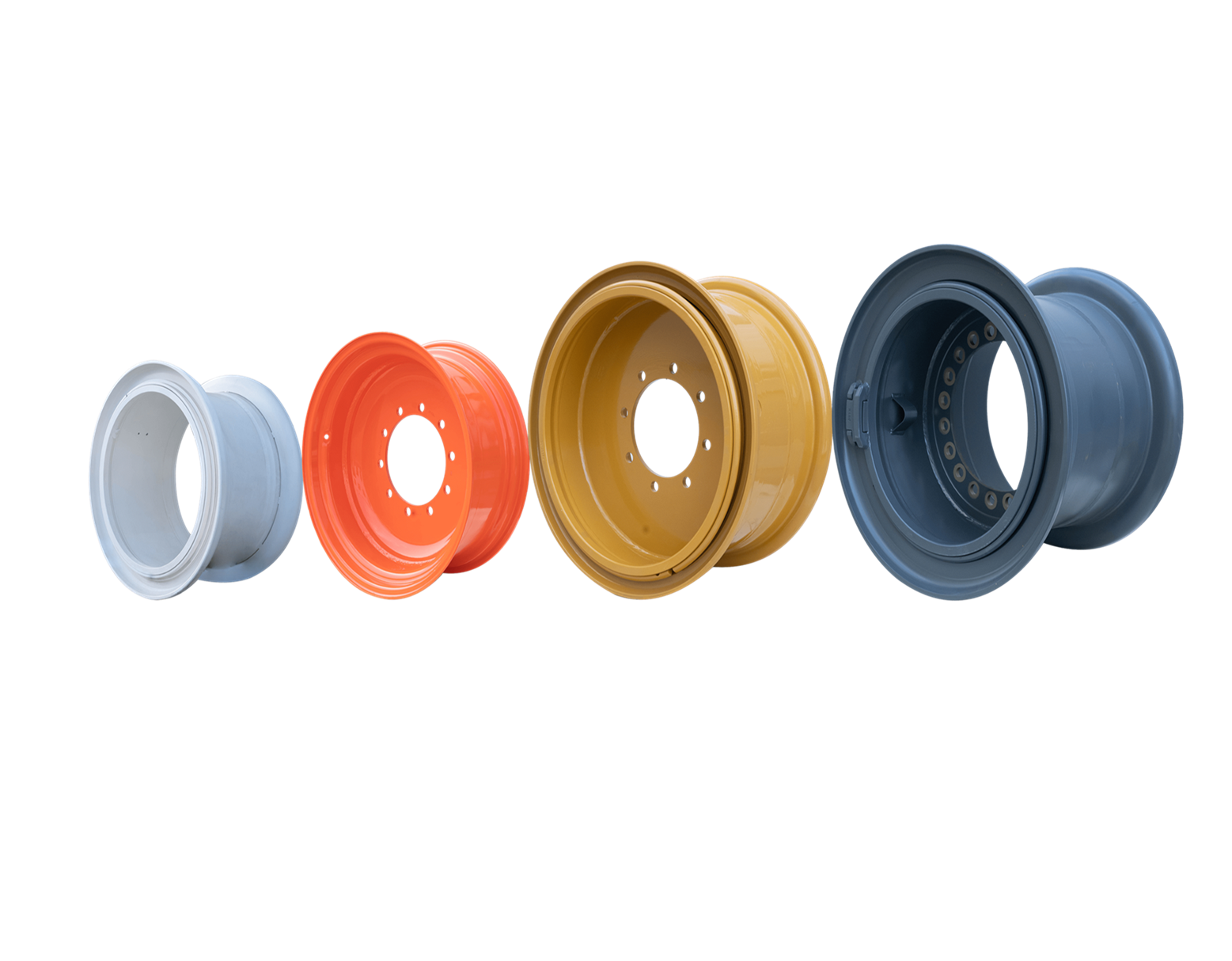

With stable product quality, extensive specification coverage, and mature supporting experience, HYWG rims have been widely used in mainstream international construction machinery and mining equipment platforms, and continue to provide global customers with standardized and customized rim solutions , including multi-piece, one-piece, and split-type structures , which are highly compatible with mainstream OTR tires .

HYWG has obtained ISO 9001 and other quality management system certifications, and has also gained recognition from well-known brands such as CAT, Volvo, and John Deere. It continuously invests in research and development, constantly optimizing product design and manufacturing processes. Its rims excel in fatigue resistance, impact resistance, and lifespan , providing more reliable protection for off-highway heavy-duty machinery and equipment .

ISO 9001

ISO 45001

ISO 14001

CAT SUPPLIER EXCELLENGE RECOGNITION

Volvo 6 SIGMA Green Belt

John Deere Supplier Special Contribution Award

Construction machinery tires are not just "a tire", but a key system component that integrates load-bearing, driving, safety, stability and protection.

HYWG believes that truly reliable construction machinery solutions always stem from the deep synergy between tires and rims. This is precisely the core value that has enabled HYWG to serve global construction machinery and mining customers for so long.

Post time: Feb-02-2026