In modern mining, quarrying, and heavy-duty engineering scenarios, the matching quality of rims and tires directly affects the stability, safety, and operating costs of the entire machine. The Liebherr L580 is widely favored by users for its superior power, stability, and durability. As one of the core components of the vehicle's load-bearing and tire systems, the choice of rims directly impacts overall machine performance, operational efficiency, and operating costs.

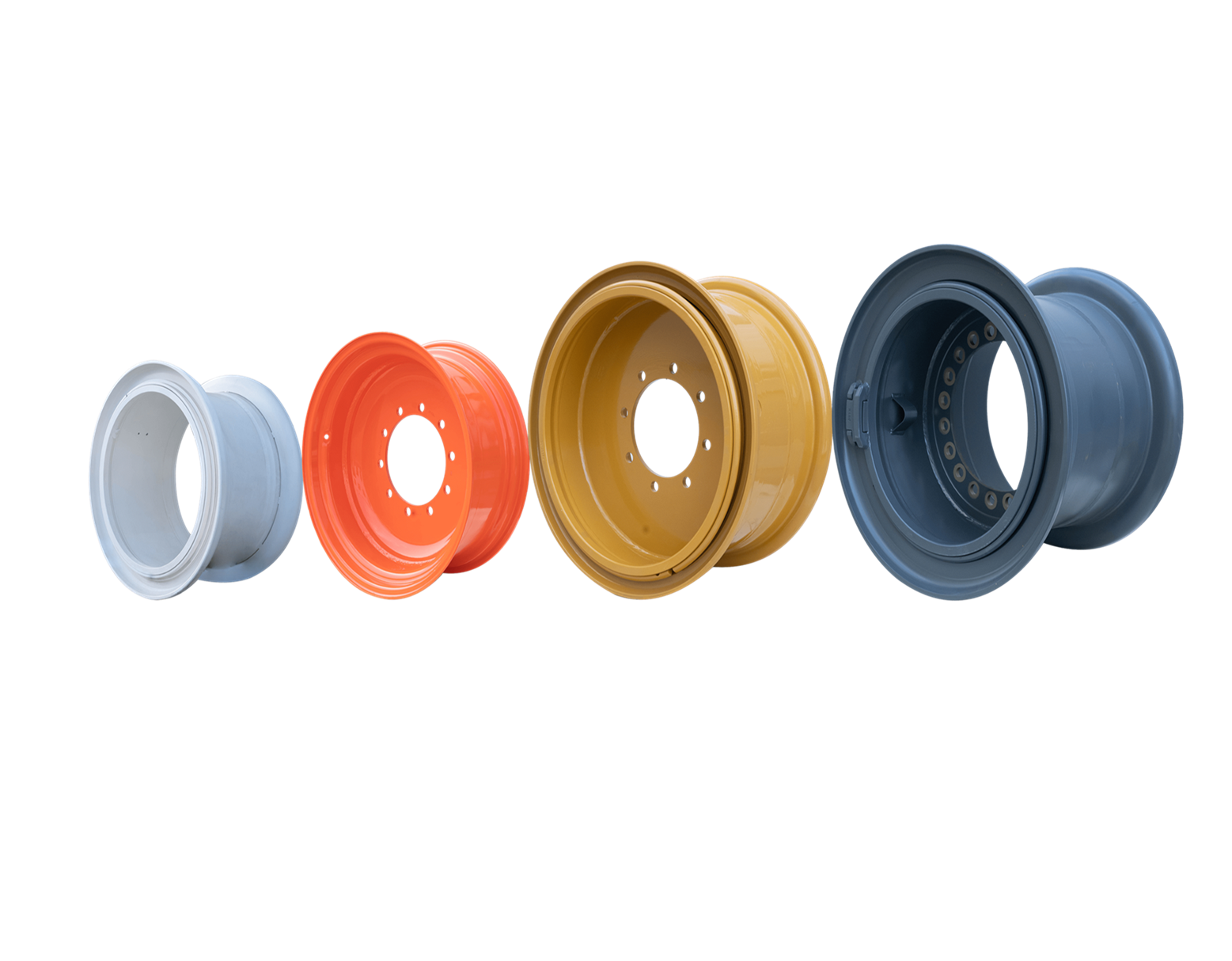

The HYWG 22.00-25/3.0 rims are designed specifically for the Liebherr L580 heavy-duty vehicle.

22.00-25/3.0 is a 3PC structure rim for TL tires, commonly used in wheel loaders. We are the original rim supplier for Volvo, Caterpillar, Liebherr, John Deere, and Doosan in China.

The Liebherr L580 wheel loader is commonly used in high-intensity work environments such as mines, quarries, and construction earthmoving. During operation, it faces frequent loading, bulldozing, and turning under heavy loads , causing the wheel flanges to bear enormous bending stress and high impact loads . The tires and rims are placed under high requirements in situations involving rocks, ditches, slope changes, and soft ground. In addition , due to long-term continuous operation, ordinary one-piece rims or wheel structures of average quality cannot guarantee long-term reliability and low-cost operation.

HYWG is a multi-piece heavy-duty wheel rim system designed specifically for heavy-duty construction machinery. Utilizing self-produced high-strength steel and an optimized cross-sectional structure, its overall bending strength and lateral impact load-bearing capacity far exceed those of ordinary one-piece wheel rims. This is particularly important for the L580 during heavy load loading, steering, and bulldozing, effectively preventing wheel rim cracking, deformation, and other malfunctions.

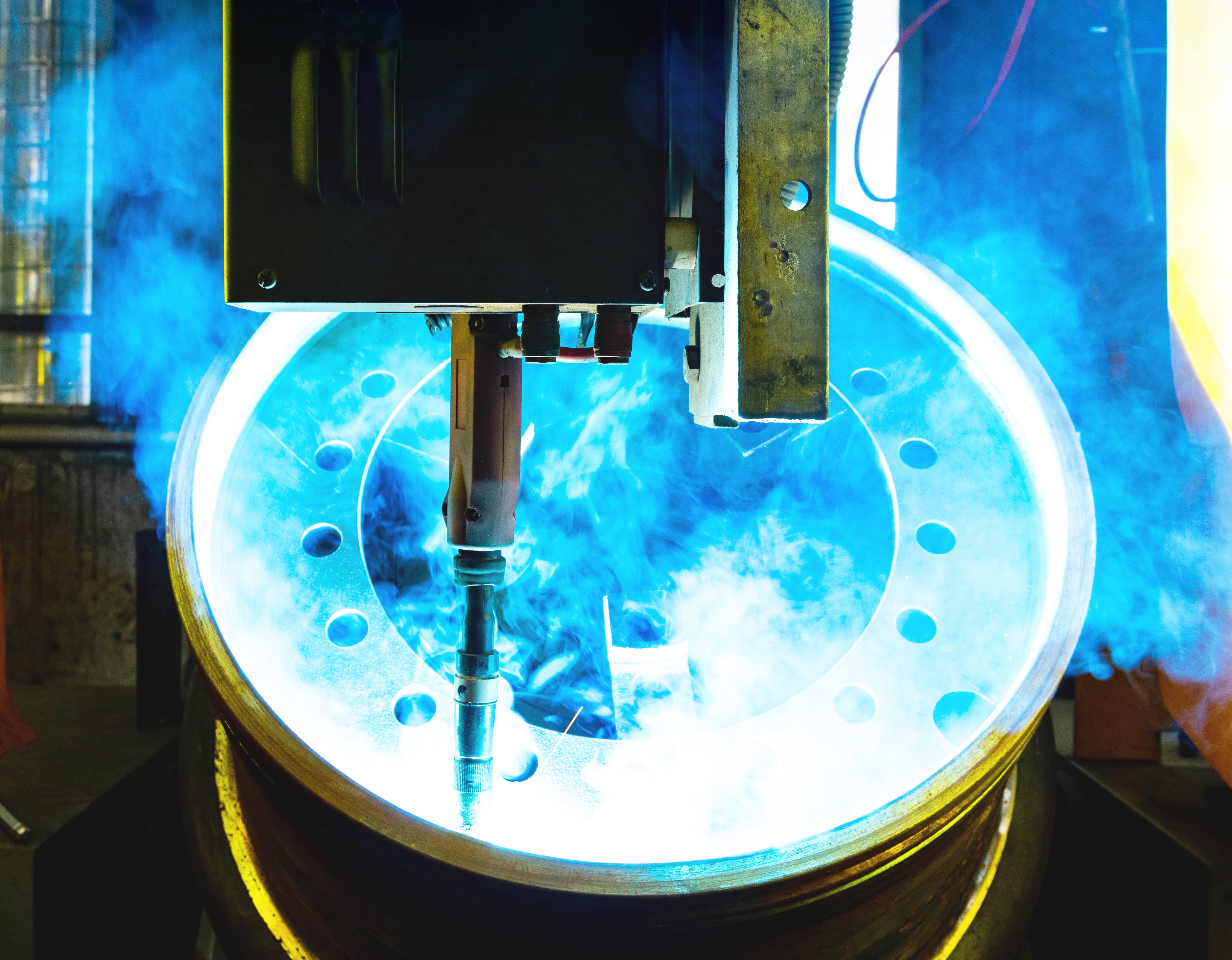

In addition, HYWG has a "one-stop" production model from steel to finished rims. From steel rolling, mold design, high-precision forming, automated welding to surface treatment and finished product inspection, it ensures that all products meet the same high standards. Every rim remains stable and reliable under the most demanding working conditions , truly realizing full-chain manufacturing and quality control of rims .

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

5.Painting

6. Finished Product

Unlike traditional one-piece rims, HYWG provides a three-piece rim design for the L580 , allowing for individual replacement of the rim lock ring , quick repair of damaged rim components , and convenient tire installation and removal, saving maintenance time and labor costs. For the L580, which operates under high-intensity, continuous conditions, this design significantly improves uptime and maintenance efficiency.

During loading, transportation, and steering, the tires of wheel loaders are subjected to complex loads. If the rim and tire are not properly matched, it can easily lead to excessive local stress on the tire , uneven tire wear, or premature tire peeling , increasing the frequency and cost of tire replacement.

HYWG rims help tires maintain the correct mounting angle and stress distribution through precise geometry matching and sealing performance, reducing irregular wear and thus extending the service life of the entire tire and rim system.

The direct value of high-quality rims isn't their lower price, but rather the reduced total cost of ownership (TCO) throughout their lifecycle: less unplanned maintenance and downtime , longer tire and rim lifespan , lower replacement frequency and parts costs , and increased overall machine uptime. For high-value equipment like the L580, the effects of TCO optimization are particularly pronounced.

Many mine and quarry users have reported that after installing HYWG 22.00-25/3.0 rims, the tire life of their L580s has increased by more than 20%; unplanned maintenance has significantly decreased; machine uptime has improved; and overall operating costs have been significantly reduced. These results demonstrate the direct contribution of choosing high-quality rims to production efficiency and profitability.

wheel loaders like the Liebherr L580 , choosing the right wheel rims is not only a necessary means to improve mechanical performance, but also an important strategy to control operating costs, improve project efficiency, and ensure on-site safety.

HYWG heavy-duty rims, with their high strength, modular design, easy maintainability, and cost-effectiveness over life, have become the ideal rim solution for the L580.

to more than ten countries, including North America, Europe, Australia, and Russia . With leading manufacturing capabilities, rigorous quality control, and a global service system, we provide customers with reliable wheel rim solutions. We are an original equipment manufacturer (OEM) wheel rim supplier in China for renowned brands such as Volvo, Caterpillar, Liebherr, and John Deere.

With its stable quality and excellent service, HYWG has gradually become a trusted partner for OTR users worldwide.

We have extensive involvement in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: Jan-04-2026