In mining and quarrying operations, the CAT 966 wheel loader consistently undertakes high-frequency, high-load core loading tasks. Compared to ordinary earthmoving operations, the mining environment places more stringent demands on the entire machine, and one of the most easily underestimated yet most critical components is the wheel rim system.

Wheel rims are not simply "tire supports," but critical safety components that directly bear the weight of the entire machine, material loads, and dynamic impacts. This is the fundamental reason why the CAT 966 must be matched with HYWG high-reliability wheel rims for mining operations.

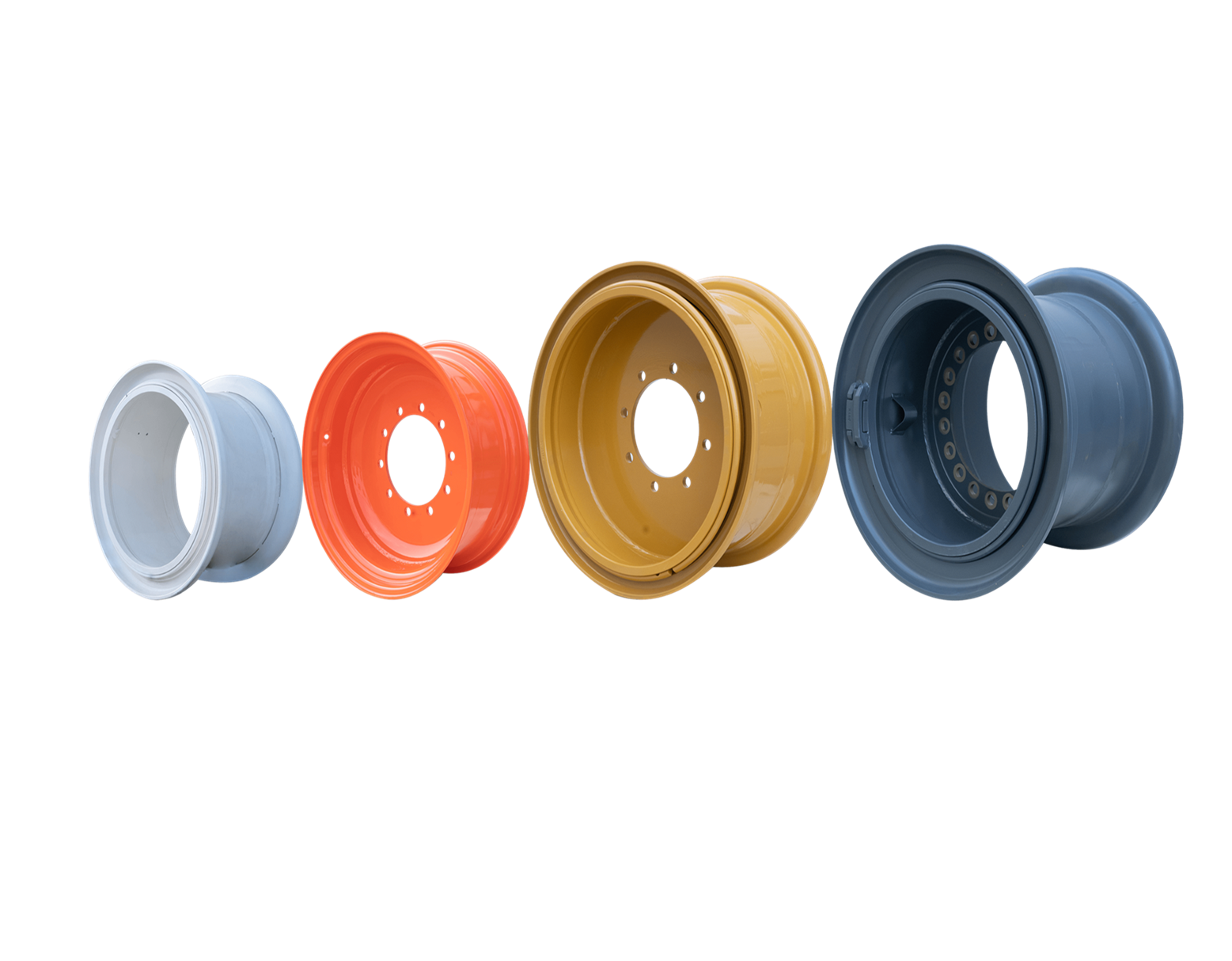

22.00-25/3.0 is a 5PC structure rim for TL tires, commonly used in wheel loaders. We are the original rim supplier for Volvo, Caterpillar, Liebherr, John Deere, Doosan in China.

In mining environments, the CAT 966 needs to handle high-frequency loading of high-density ore , full-load turning, emergency stops, and reversing . During operation, it will encounter repeated impacts on gravel roads and potholes , requiring long-term continuous operation. Once it stops , it will incur extremely high costs.

Under these operating conditions, the wheel rim needs to withstand the continuous high load of the machine's own weight plus a single bucket of 6-7 tons . Strong impact loads are also generated during loading, bucket lowering, and braking . Long-term cyclical operation will generate fatigue loads. Under these harsh conditions, ordinary wheel rims are extremely prone to deformation, cracks, weld fatigue , and even safety accidents.

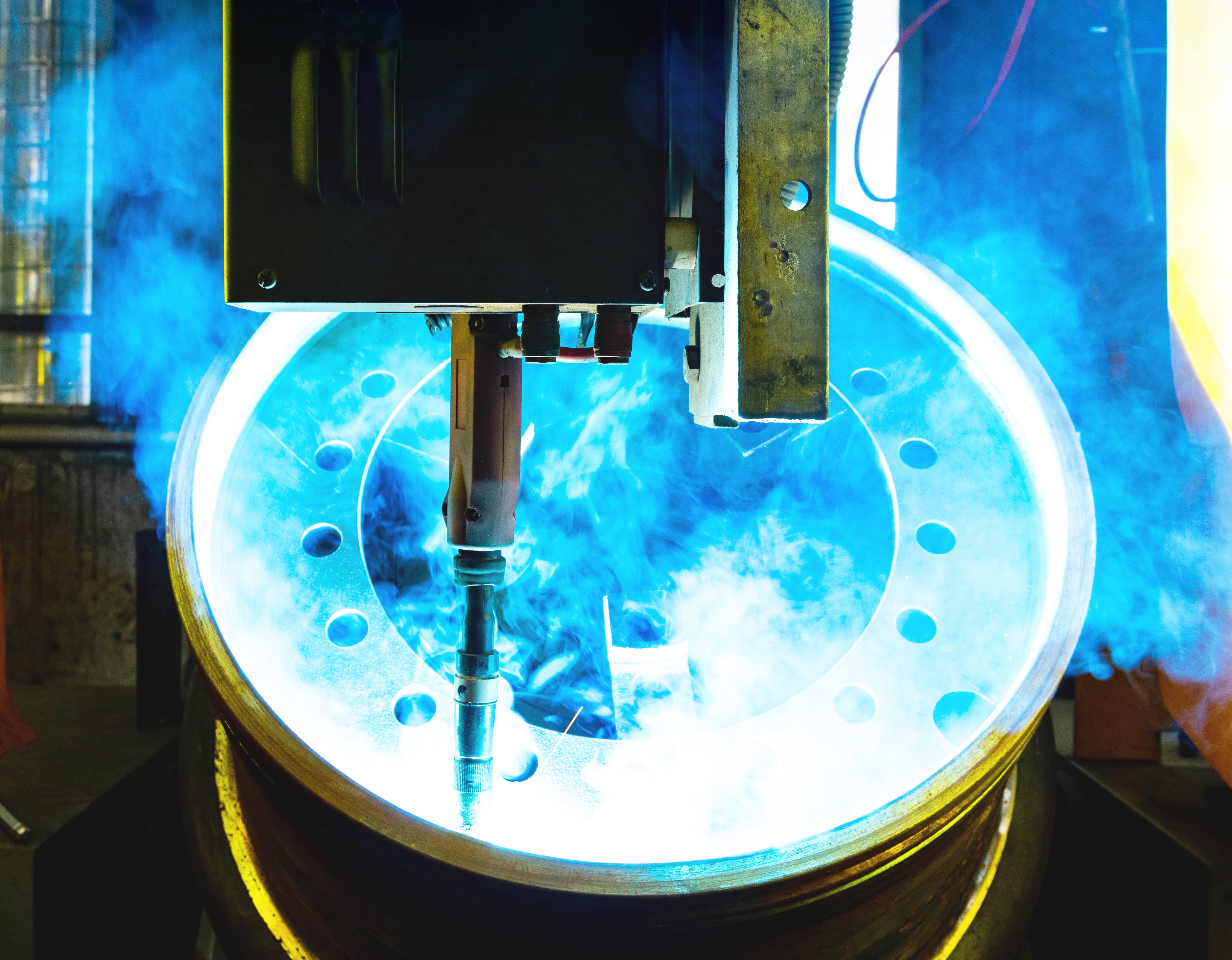

HYWG possesses the capability to independently produce steel profiles for wheel rims , marking a watershed moment in high-end manufacturing capabilities within the OTR wheel rim sector. The advantage it brings goes far beyond simply "making its own materials"; it determines the safety ceiling, consistency, and long-term reliability of the wheel rims from the very beginning.

The safety and lifespan of OTR rims are determined from the source of materials. This ensures that the product surpasses ordinary standard rims in concentricity , fatigue resistance , weld strength , and service life . High-strength, high-quality steel guarantees excellent fatigue and impact resistance .

It possesses a complete industrial chain production from steel to finished wheel rims , including steel rolling, mold design, high-precision forming, automated welding, surface treatment, and finished product inspection . This "one-stop" production model ensures that all products meet uniform high standards, truly realizing full-chain manufacturing and quality control of wheel rims.

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

5.Painting

6. Finished Product

HYWG's superior manufacturing conditions and use of high-strength proprietary steel enhance the rim's resistance to deformation and structural stability . Even under fully loaded loading and frequent turning conditions, the CAT 966 maintains stable rim shape.

On mining CAT 966 trucks, any problems with the wheel rims have a cascading effect . Rim deformation can lead to abnormal tire wear and leaks . Fatigue cracks in the wheel rims can cause sudden vehicle shutdowns and pose safety hazards . Frequent wheel rim replacements reduce equipment uptime and increase operating costs .

For mining customers, wheel rim failure is not a parts issue, but a production, safety, and cost issue.

Therefore, what the mining CAT 966 needs is not a rim that can be "installed", but a highly reliable rim that can work stably for a long time under extreme working conditions.

over 20 years of experience in the OTR and engineering machinery rim field , HYWG's rim design philosophy originates from heavy-duty and mining conditions.

HYWG has a research and development team composed of senior engineers and technical experts who will strengthen the rim flange and rim seat area , optimize stress distribution, reduce fatigue concentration , and improve the ability to withstand lateral forces and impact loads , especially suitable for high-density ore and rock conditions, based on the mining characteristics of CAT 966 .

With a comprehensive after-sales service system, every HYWG rim undergoes rigorous testing, including dimensional accuracy and concentricity checks , weld quality inspection , tire compatibility and assembly verification , and load capacity and safety margin control . This ensures the rim's consistency and predictability in actual mining conditions. Timely and efficient technical support and after-sales maintenance are also provided to guarantee a smooth user experience.

In mining operations, the performance of the CAT 966 depends on the reliable support of every key load-bearing component.

HYWG's high-reliability rims are wheel-end solutions designed specifically for mining. They not only bear weight, but also ensure safety, efficiency, and the continuous operation of the mine.

HYWG 's products are exported to more than ten countries, including North America, Europe, Australia, and Russia . With leading manufacturing capabilities, rigorous quality control, and a global service system, we provide customers with reliable wheel rim solutions. We are an original equipment manufacturer (OEM) wheel rim supplier in China for renowned brands such as Volvo, Caterpillar, Liebherr, and John Deere , becoming a trusted partner for OTR ( Original Equipment Manufacturer) users worldwide .

We have extensive involvement in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: Jan-04-2026