KALMAR is a well-known port and heavy-duty logistics equipment manufacturer from Finland. It is famous for its high-quality and high-reliability heavy-duty forklifts, which are widely used in ports, steel mills, lumber mills, logistics hubs, etc. It is the first choice for handling various ultra-heavy materials .

.jpg)

The core advantages of KALMAR heavy-duty forklifts are mainly reflected in the following aspects :

1. Super strong carrying capacity

It provides lifting capacities ranging from 10 tons to 72 tons, suitable for various ultra-heavy working conditions.

The gantry is sturdy in design and has high lifting stability, making it suitable for transporting steel coils, large structural parts, heavy containers, etc.

2. High-efficiency engine and energy-saving system

Equipped with low-emission and high-torque engines such as Volvo and Cummins, it has strong power.

Equipped with an energy-saving control system (EcoDriveMode), it can effectively reduce fuel consumption and achieve an energy saving rate of more than 15%.

3. Excellent ergonomic design

The cab has a wide field of vision, comfortable seats, and sensitive joysticks to reduce driver fatigue.

High-end models are equipped with multi-function touch screen, camera assistance, air conditioning, wireless communication, etc.

4. Reliability and durability

The structural components are reinforced to adapt to high-intensity continuous operation.

It can operate stably in harsh environments such as extreme cold, heat, and dust.

Because heavy-duty forklifts need to withstand loads of 10 tons to 72 tons or even higher, the rims they are equipped with must have extremely high compressive strength and structural rigidity. The rims play an extremely important role in the performance of the entire machine, especially in dealing with overweight loads, high-intensity operations and harsh ground environments. The quality and matching of the rims directly affect the safety, stability, service life and operating efficiency of the forklift .

HYWG is China's No.1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards .

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing . We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

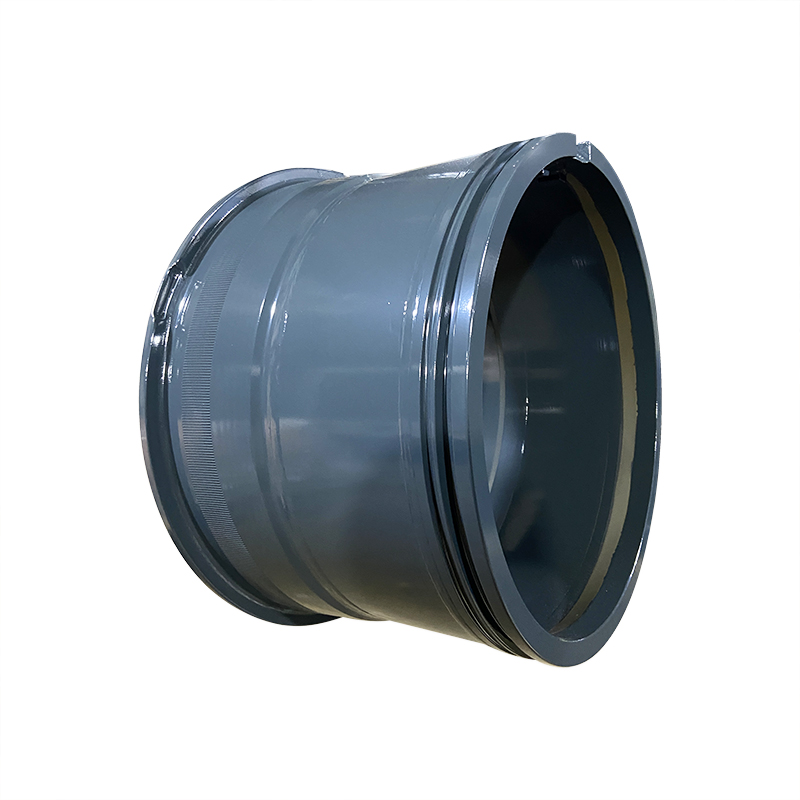

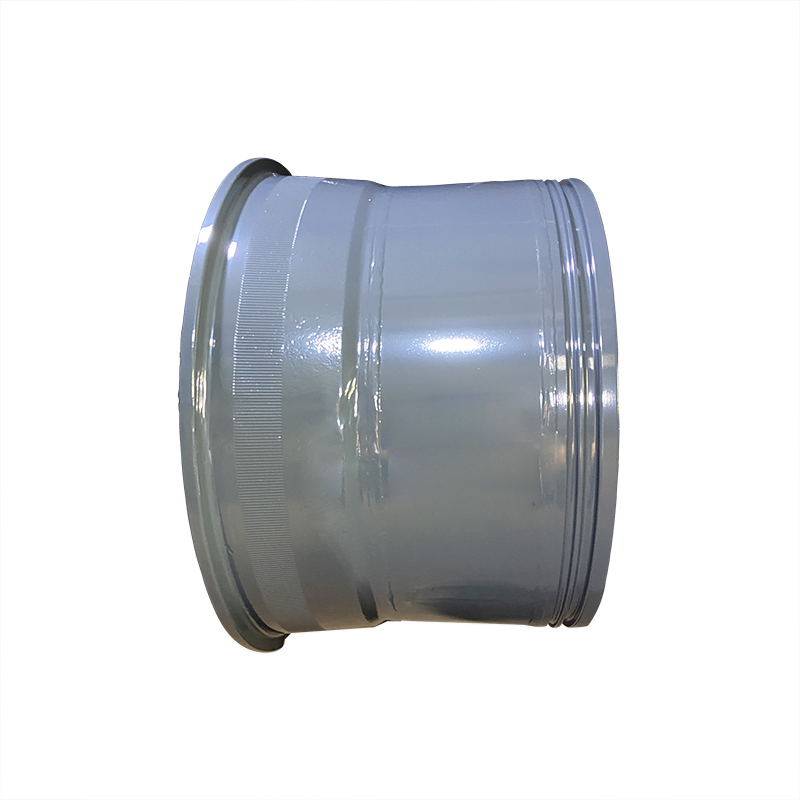

According to the working performance of KALMAR heavy-duty forklift, we developed and produced 1 3.00-25/2.5 rims that are suitable for it .

The 13.00-25/2.5 rim for Kalmar heavy-duty forklifts is a commonly used rim specification for medium and high tonnage forklifts. It is suitable for models with a lifting capacity of about 16 tons, especially models such as Kalmar DCG160, DCG180 , etc.

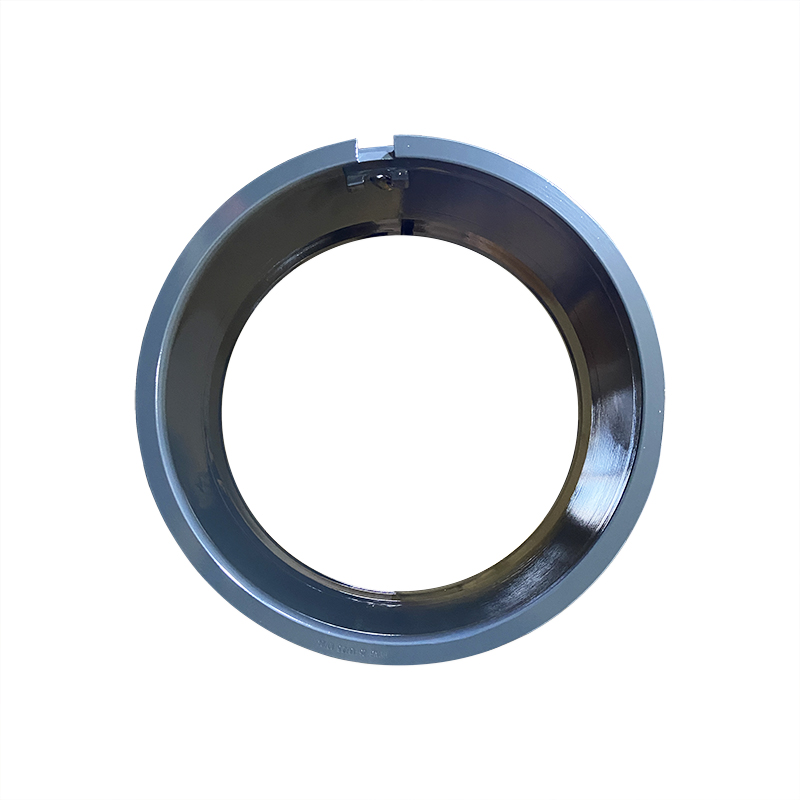

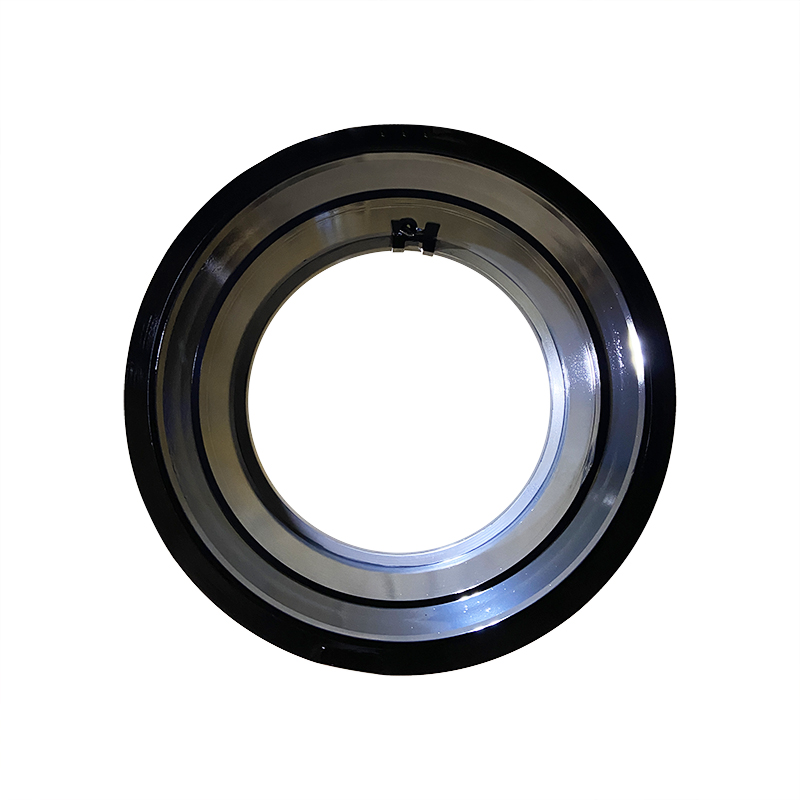

13.00-25, suitable for 25-inch tread tires with a width of 13.00 . 2.5 inches, indicating the thickness of the rim lock ring area (suitable for heavy-duty structures) . 5 PC split rims, easy to change quickly .

What are the advantages of KALMAR heavy-duty forklifts equipped with 13.00-25/2.5 rims?

The core advantages of KALMAR heavy-duty forklifts with 13.00-25/2.5 rims

1. Excellent balance between carrying capacity and adaptability

The 13.00-25/2.5 wheel rim can carry a single wheel load of approximately 10 to 16 tons, which just matches the load-bearing requirements of KALMAR's medium and heavy-duty forklifts.

It is also suitable for tires of size 13.00-25 or 14.00-25, and is compatible with solid tires or pneumatic tires, allowing for flexible selection based on the working environment.

2. Strong structure, suitable for heavy-duty and high-frequency operations

The 2.5-inch thick flange structure provides stronger torsional and compressive resistance, and is particularly suitable for high-frequency take-off and landing and heavy-load handling, such as steel, mechanical equipment, containers, etc.

It adopts 5PC structure with strong impact resistance, suitable for harsh working conditions such as ports and steel mills.

3. High maintenance efficiency and convenient tire replacement

The split structure design allows the tire bead, lock ring or carcass to be quickly replaced without removing the entire tire, greatly reducing maintenance time.

It is particularly suitable for task-intensive places such as port yards, timber mills, dock unloading areas, etc., where high equipment attendance rates are required.

4. Improve vehicle stability and handling

When used with high-quality heavy-duty tires, it can improve the lateral stability, anti-rollover ability and braking response of KALMA forklifts under load.

Especially when transporting high center of gravity or eccentric loads (such as steel coils, large components), the 13.00-25/2.5 rim provides a solid support platform.

5. Adapt to various working environments

Adaptable solid tires can be used on sharp, gravel, steel chip ground to prevent puncture;

Adaptable pneumatic tires can be used on asphalt roads and concrete floors to improve comfort and energy efficiency .

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Jun-21-2025