What Are The Main Advantages Of a Wheel Loader?

Wheel loaders are a type of engineering machinery widely used in construction, mining, ports, road construction and other fields. Their main advantages include the following aspects:

1. Strong mobility

Because they are equipped with tires instead of tracks, wheel loaders have higher travel speeds on flat or semi-hard surfaces.

It can quickly move from one working point to another, improving work efficiency.

2. Easy transition

It can be driven directly on the road without the need for special transport vehicles for transfer, thus saving transportation and dispatch costs.

3. High versatility

In addition to shoveling operations, a variety of accessories (such as wood clamps, sweepers, snow pushers, etc.) can be replaced as needed to achieve multi-purpose operations.

4. Good controllability

The hydraulic steering system and advanced operating system make it flexible and precise to control, with light operating burden, making it suitable for long-term operation.

5. Easy maintenance

Compared with crawler equipment, the tire system has a simple structure, convenient maintenance and low maintenance cost.

6. Less damage to the ground

The tire exerts relatively small pressure on the ground and is not easily damaged when operating on urban roads or concrete floors. It is suitable for urban engineering or garden maintenance.

7. High operating efficiency

They usually have a larger bucket capacity and are suitable for fast handling and loading of bulk materials (such as sand, coal, ore, etc.).

8. Relatively good fuel economy

The driving resistance is smaller than that of crawler equipment, and the fuel consumption is lower under the same working conditions.

These advantages make wheel loaders an indispensable piece of equipment in many industries, providing efficient and flexible solutions for a variety of material handling and earthmoving projects.

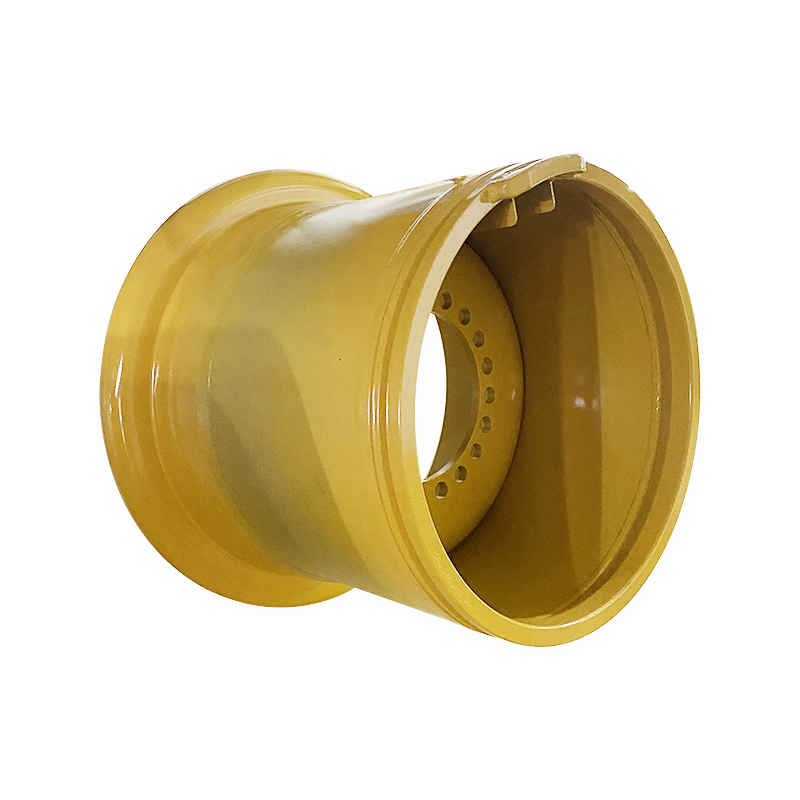

The wheel rims of a wheel loader play a vital role when it is working:

1. Support tires and carry loads: The rim is the installation base of the tire, which directly bears the air pressure inside the tire and the huge external load. When the wheel loader is loading, transporting and unloading, the rim must be strong enough to withstand the weight of the material, the weight of the machine itself, and the impact and torque generated during the operation.

2. Transmit driving force: The rim transmits the driving force generated by the engine to the tire through the connection with the axle, so that the loader can move forward or backward. Its structural strength and connection stability directly affect the effective transmission of driving force.

3. Ensure driving stability: The manufacturing accuracy and dynamic balance of the rim are crucial to the driving stability of the wheel loader. Unbalanced rims can cause the vehicle to vibrate at high speeds, affecting operating comfort and accelerating the wear of tires and suspension systems.

4. Impact on tire life and performance: The right rim size and type can ensure that the tire is properly installed and performs optimally. The condition of the rim (such as deformation, corrosion) will directly affect the wear pattern and service life of the tire.

Therefore, the quality, design and maintenance of the rims are of great importance to the overall performance, safety and economy of the wheel loader.

HYWG is China's No.1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, John Deere, and JCB.

Caterpillar is an important brand in the field of wheel loaders . We provide 19.50-25/2.5, 3PC rims for its CAT 950M wheel loader.

19.50-25/2.5, 3PC rim is a high-strength industrial rim commonly used on medium and large wheel loaders. It is suitable for harsh working environments such as mines and construction sites.

Such rims are easy to maintain and disassemble, and no professional hydraulic equipment is required for tire replacement or repair. When there is local damage, individual parts (such as the lock ring) can be replaced without replacing the entire rim. The multiple structure design can share stress and improve heavy-load stability.

What are the advantages of CAT 950M wheel loader?

What Are The Advantages Of The Komatsu Wa500-6 Wheel Loader?

CAT950M wheel loader is a medium-sized and efficient loading equipment launched by Caterpillar. It is widely used in construction, mining, ports and industrial material handling. Compared with similar models, it has many significant advantages, as follows:

Main advantages of CAT950M

1. Strong power and high production efficiency

Equipped with Cat C7.1 ACERT™ engine, it meets Tier 4 Final/National IV emission standards and provides a power output of approximately 186 kW (250 hp).

The power response is fast and the speed is not easy to drop during heavy load operation, which is suitable for frequent loading and unloading operations.

2. High fuel efficiency

Equipped with Economy Mode, it intelligently controls engine speed and hydraulic power output to reduce fuel consumption.

Caterpillar's Intelligent Power Management system intelligently adjusts fuel delivery based on workload.

3. Intelligent configuration

Optional CatPayload dynamic weighing system: real-time weighing, improved loading accuracy, and reduced overloading risks.

Support ProductLink™ remote management system: view equipment status, fuel consumption, operating data, fault warning, etc., to facilitate remote operation and maintenance and scheduling.

4. Strong operating comfort

Equipped with a closed shock-absorbing cab with air conditioning, hydraulic seat and multi-function LCD display.

The electro-hydraulic operating lever (EH control) is sensitive to operation, quick to respond, and reduces operator fatigue.

The cab has a wide field of view and is equipped with a rearview camera to improve operating safety.

5. Easy maintenance

The inspection points are concentrated, and the machine cover and maintenance door have a large opening angle, which is convenient for quick inspection and replacement of filter elements, hydraulic oil, etc.

Extended engine oil, hydraulic oil and filter change intervals reduce maintenance frequency and costs.

6. Multi-function and attachment compatibility

Various working accessories can be quickly replaced, such as rock bucket, light material bucket, fork, wood clamp, snow shovel, etc., to expand the scope of application.

CatFusion quick-change device is used, making attachment switching quick and easy.

7. Reliable chassis and rim system

It is usually equipped with 19.50-25/2.5 (3PC) rims, compatible with 23.5R25 high-strength tires, and adaptable to complex working conditions.

The frame structure is solid, the articulated system is strong in torsion resistance and has a long service life, making it suitable for frequent heavy-load work.

We are China's No. 1 off-road wheel design and manufacturer, and also the world's leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards. We have mature technology in the research and development and production of mining vehicle rims. We have extensive involvement in mining vehicles such as mining dump trucks, rigid dump trucks, underground mining vehicles, wheel loaders, graders, mining trailers, etc. We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. You can send me the rim size you need, tell me your needs and troubles, and we will have a professional technical team to help you answer and realize your ideas.

We not only produce mining vehicle rims, but also widely involved in engineering machinery, forklift rims, industrial rims, agricultural rims and other rim accessories and tires. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, John Deere, etc.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Jun-06-2025