What are the main advantages of underground mining?

Underground mining has its own unique advantages over open pit mining, especially under certain geological and economic conditions. The main advantages of choosing underground mining include:

1. Ability to mine deep deposits

This is the core advantage of underground mining. Many valuable mineral resources, such as gold, silver, copper, platinum, zinc, and some coal seams, are buried deep underground and cannot be economically or effectively reached by open-pit mining methods (such as open pit mining and strip mining). Underground mining can cost-effectively access these deep ore bodies by excavating shafts, ramps and tunnels deep into the ground.

2. Reduce surface disturbance and environmental impact

Compared with open-pit mining, underground mining causes much less damage to the surface landscape.

Smaller surface footprint: Underground mines require only a relatively small surface area for infrastructure (such as shafts, vents, concentrators, etc.) without the need for large-scale clearing of vegetation and removal of topsoil and rock.

Small visual impact: Since most operations take place underground, underground mines do not leave huge "scars" or deep pits like large open-pit mines, and have less visual impact on the natural landscape.

Less noise and air pollution: Most machinery and mining activities take place underground, helping to confine noise and dust underground and reduce disturbance to communities and wildlife near the surface.

Protecting the ecosystem: The surface vegetation, rivers and ecosystems are less disturbed, which helps to protect the surface ecological environment.

3. Higher ore grade and selectivity

Targeting high-grade ore bodies: Underground mining can more accurately target deep, high-grade veins or ore bodies, thereby obtaining higher quality ore and reducing the generation of waste rock.

Reduced Waste: Because extraction is more selective, underground mining typically produces less waste rock and tailings, helping to reduce the need for waste disposal.

4. Not affected by weather conditions

Underground mining operations are mainly carried out in a closed underground environment, which is almost unaffected by severe weather conditions on the surface (such as heavy rain, heavy snow, strong winds, and extreme temperatures). This helps maintain the continuity and stability of production and reduce downtime caused by weather reasons.

5. Longer mine life

Many deep mineral deposits have huge reserves, and underground mining can maintain longer mining cycles. Some mines can even operate for decades or even hundreds of years, bringing long-term, stable profits and employment to the companies.

Although underground mining has many advantages, it is also accompanied by higher costs, more complex operations and higher safety risks. Therefore, it is very important to choose the right process and equipment. The importance of wheel rims in underground mining vehicles is very prominent, which is related to the efficiency, safety and equipment life of mine production.

HYWG is China's No.1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies to maintain a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing.

provide many types of wheels for Volvo, Caterpillar, Komatsu, Liebherr, John Deere, Huddig and other well-known brands.

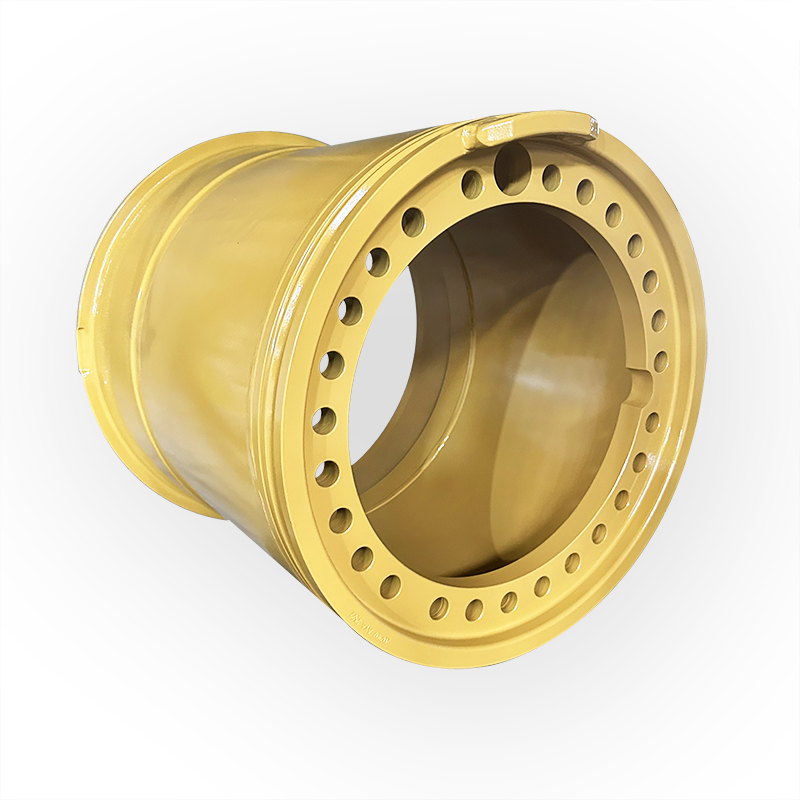

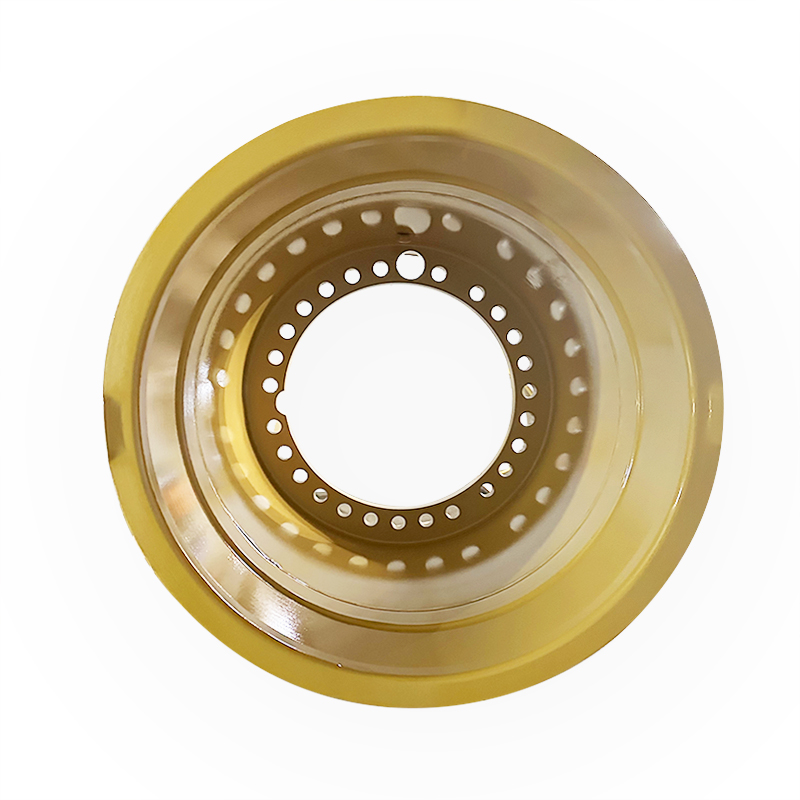

22.00-25/3.0 rim is a large-size rim equipped on Carter underground mining vehicles and is suitable for 22.00-25 size tires.

The main advantages of 22.00-25/3.0 are

1. High load-bearing capacity : 3.0-inch wide rims can better support large-section tires, have strong load-bearing capacity, and are suitable for mining and heavy-load conditions; suitable for 22.00-25 large-ply tires to ensure vehicle load and stability.

2. Adapt to harsh environment : The rim is made of high-strength steel with excellent impact resistance and wear resistance; after anti-corrosion treatment, it is suitable for wet, muddy, rocky and other mining environments.

3. Easy maintenance : The five-piece structure design facilitates quick removal and installation of tires and replacement of parts; reduces maintenance time and costs, and improves mine production efficiency.

4. Strong compatibility : widely compatible with various mining tire brands and types, easy to purchase and replace; commonly used in large wheel loaders, dump trucks and mining transport vehicles.

What are the advantages of using 22.00-25/3.0 rims on underground mining vehicles?

Underground mining vehicles are equipped with 22.00-25/3.0 five-piece rims, which have significant structural, safety and maintenance advantages, and are particularly suitable for ore transportation and loading operations in high-intensity and harsh environments. The following are its main advantages in underground mining applications:

1. Strong load-bearing and impact resistance

Strong load-bearing performance: 22.00-25 is a rim size with a large section and wide tire. The matching tire has a high load capacity and can meet the long-term heavy-load operation of underground mining vehicles;

Stable structure: 3.0-inch wide flange design enhances the fit between the tire and the rim to prevent blowouts, tears and debonding.

2. Improve vehicle trafficability and stability

Wider contact area: The matching wide tires improve traction and grip performance, making it more passable on slippery, soft or gravel roads;

More stable driving: Reduce vehicle bouncing and slipping on rugged roads, and improve operator comfort and safety.

3. Five-piece structure for easy maintenance

Underground mines have small spaces and difficult maintenance. The five-piece rim structure allows for quick removal of tires, saving downtime, reducing damage during tire loading and unloading, and extending the service life of tires and rims.

4. Adapt to harsh environment, corrosion and wear resistance

The 22.00-25/3.0 rim is made of high-strength steel with zinc spraying or electrophoretic coating on the surface, which has excellent anti-corrosion performance; it can withstand the harsh environment of high humidity, acidic water seepage, dust, etc. in the mine.

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: May-26-2025