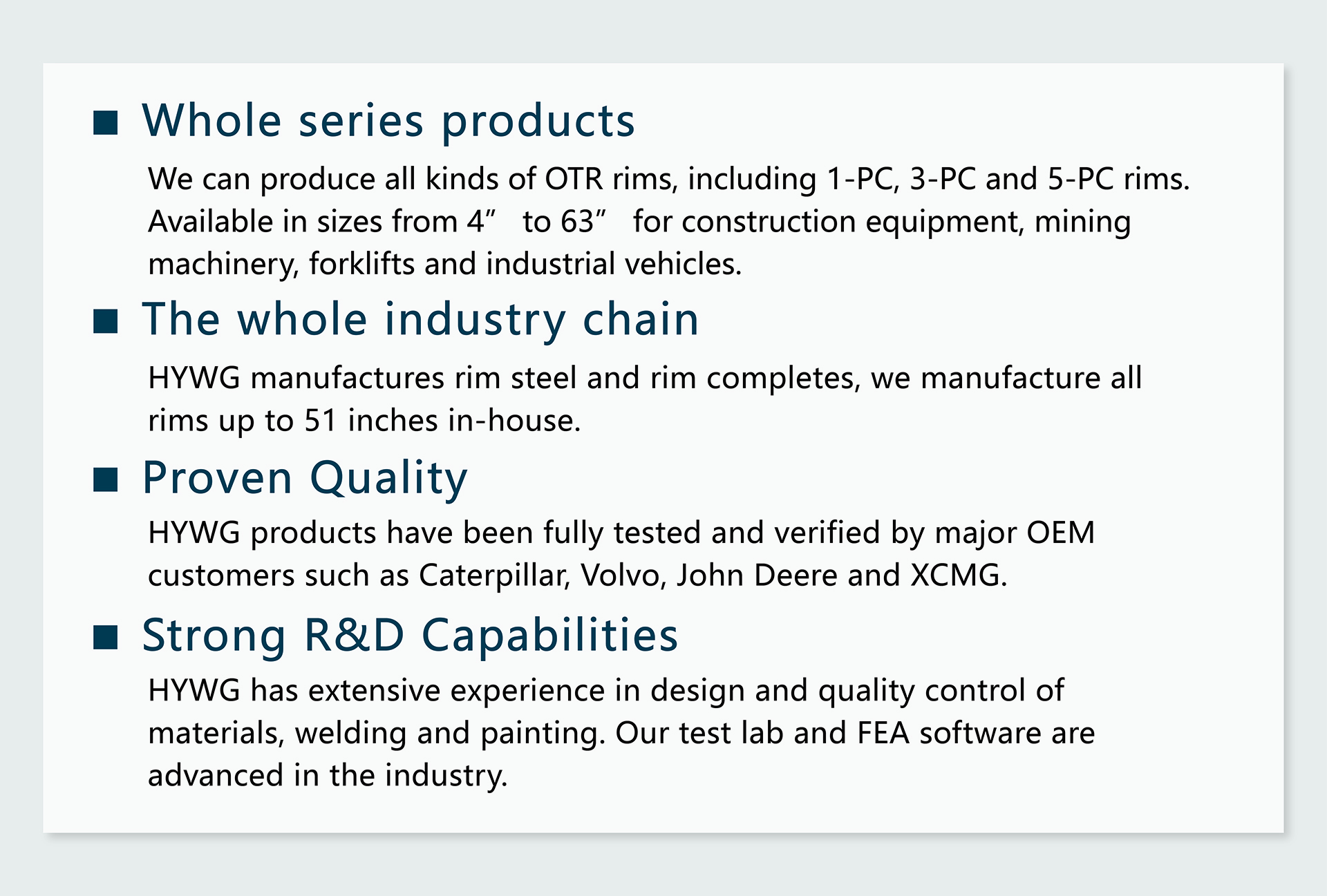

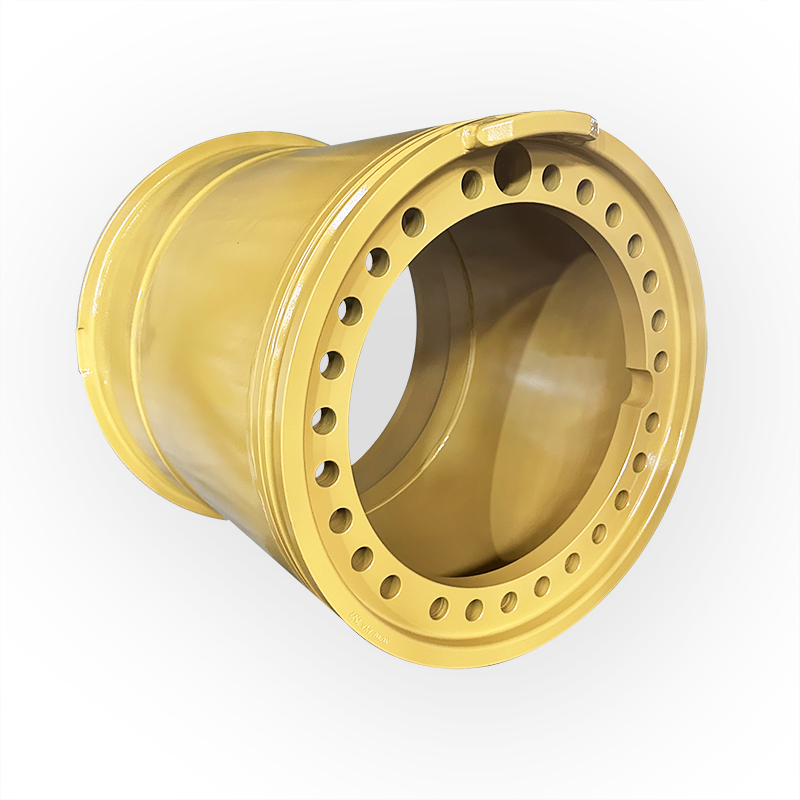

22.00-25/3.0 rim for Mining Underground mining CAT

25.00-29/3.5 rim for Mining Underground mining CAT R2900

Here are the key features and characteristics of a Komatsu wheel loader:

The CAT R2900 is a model of underground mining loader manufactured by Caterpillar Inc., often referred to simply as Cat. Caterpillar is a well-known manufacturer of heavy machinery and equipment used in construction, mining, and various industrial applications. The R2900 is part of Cat's lineup of mining loaders designed specifically for underground mining operations.

The CAT R2900 is designed to handle the demanding conditions of underground mining, where space may be limited, and rugged equipment is required to move materials and perform various tasks. It is known for its reliability, durability, and performance in challenging environments. Some of the key features of the CAT R2900 might include:

1. **Engine:** Equipped with a powerful diesel engine designed to provide sufficient power for loading and hauling tasks in underground mines.

2. **Bucket Capacity:** The loader's bucket capacity can vary based on the specific model and configuration, but it is designed to efficiently scoop and transport materials.

3. **Hydraulic System:** The hydraulic system allows for precise and efficient control of the loader's movements, such as lifting, lowering, and tilting the bucket.

4. **Operator Comfort:** The cab of the R2900 is designed to provide a comfortable and safe environment for the operator, with controls and features that facilitate ease of operation.

5. **Safety Features:** Mining equipment like the R2900 often includes safety features such as advanced visibility, operator alerts, and integrated technologies to enhance the safety of both the equipment and the personnel.

6. **Durability:** The CAT R2900 is built to withstand the harsh conditions of underground mining, with features that prevent damage and increase the longevity of the machine.

7. **Customization:** Caterpillar typically offers various configurations and options to cater to different mine requirements and operator preferences.

Please note that specific details and features of the CAT R2900 may vary based on the model year and any updates made by Caterpillar since my last knowledge update in September 2021. If you're looking for the most accurate and up-to-date information about the CAT R2900, I recommend visiting Caterpillar's official website or contacting their authorized dealers.

More Choices

| Underground mining | 10.00-24 |

| Underground mining | 10.00-25 |

| Underground mining | 19.50-25 |

| Underground mining | 22.00-25 |

| Underground mining | 24.00-25 |

| Underground mining | 25.00-25 |

| Underground mining | 25.00-29 |

| Underground mining | 27.00-29 |

| Underground mining | 28.00-33 |