The rim is a key component under any construction vehicle. The rim is often overlooked, and it is the foundation of the entire wheel assembly. It plays a key role in determining vehicle performance, safety, and service life. The rim is the key interface between the tire and the vehicle, ensuring a safe and stable connection.

The rim in construction refers to the key component that mounts the tire and supports its shape. It is a part of the wheel, mainly used in construction engineering machinery vehicles such as loaders, forklifts, cranes, mining transport vehicles, etc., and is widely used in construction, mines, ports and other working environments.

The main functions of the rim of construction equipment are:

1. Fix the tire and provide firm support to ensure that the tire does not fall off at high speed or high load.

2. Support the load, bear the weight of the equipment and external load.

3. Transmit power to help the vehicle drive effectively in complex terrain.

4. Heat dissipation function, through the structural design of metal materials, reduce the overheating of the tire in a high-temperature working environment.

The rims in construction equipment are divided into the following categories:

1. Integral rims

This type of rim has a simple structure and high strength, and is often used in small and medium-sized construction machinery.

2. Multi-piece rims

This type of rim consists of multiple parts such as rim seat, lock ring, side ring, etc., which is suitable for large construction machinery and mining vehicles. Easy to disassemble and maintain.

3. Split rims

This type of rim consists of two parts, which are fixed and connected by bolts, making it easy to replace and repair.

The rims in construction are key load-bearing and supporting components. HYWG is China's No. 1 off-road wheel designer and manufacturer, and also the world's leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards. We have more than 20 years of experience in wheel manufacturing.

We have mature technology in the research and development and production of rims. We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. Our rims not only involve a variety of vehicles, but also are the original rim suppliers in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

The rims developed and produced by our company meet some of the requirements required by construction vehicles at work.

1. High load-bearing capacity: The steel used in our steel rims is of high strength and can withstand heavy weight and strong impact, which is particularly suitable for heavy machinery, mining transportation vehicles and construction machinery.

2. Durability: Due to the use of high-quality steel in production and special treatment (such as heat treatment or anti-corrosion coating), steel rims have high wear resistance and corrosion resistance and can be used for a long time in harsh environments.

3. Effectively reduce costs and improve use efficiency: Compared with materials such as aluminum alloys, steel rims have a lower manufacturing cost, which makes them more common in some large-scale heavy vehicles. It becomes an ideal choice for cost-sensitive projects and applications, especially for medium-sized construction machinery and mining transportation vehicles.

4. Improve impact resistance: The elasticity and toughness of steel enable steel rims to effectively resist the impact from uneven ground, stones, potholes, etc., reducing the risk of damage.

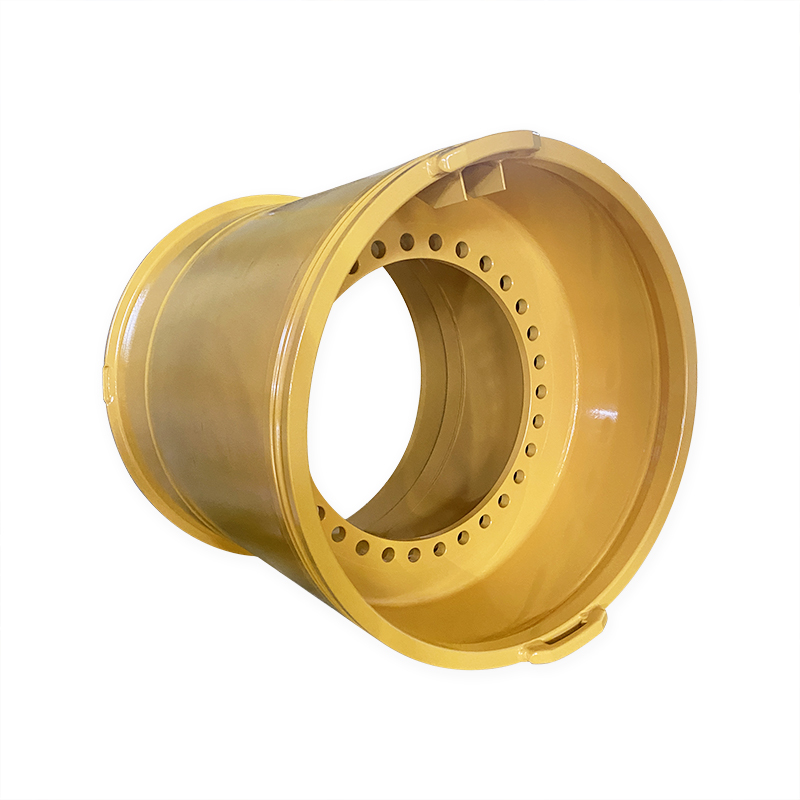

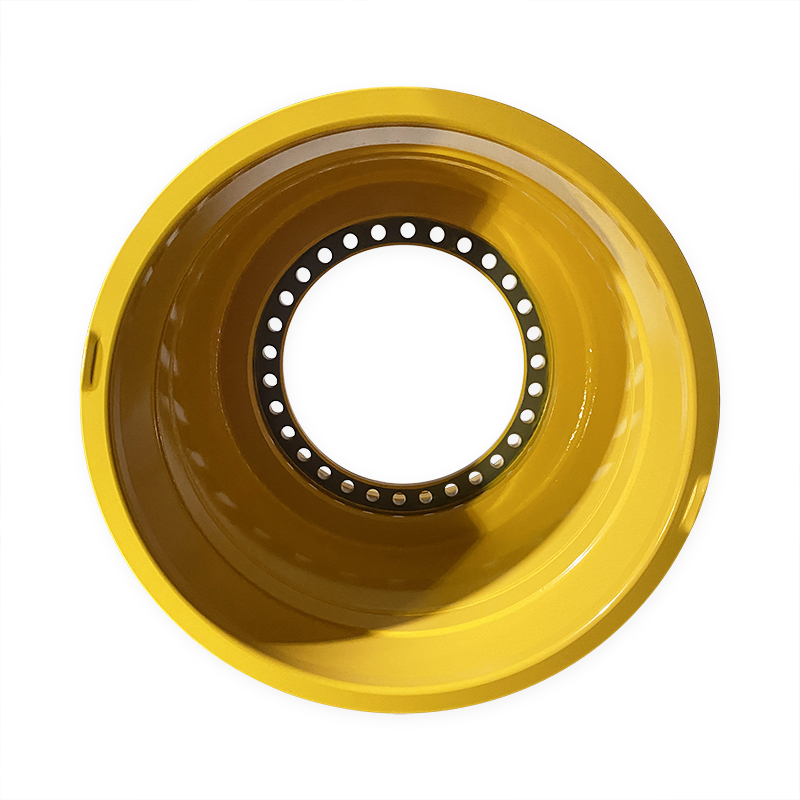

Our company provides rims with a size of 27.00-29/3.5 for the Volvo L260H large wheel loader, a popular model among Volvo construction vehicles.

3.jpg)

Volvo L260H is a high-performance large wheel loader with powerful power and flexible operation capabilities. It is widely used in various heavy-duty operation scenarios such as quarry and mining operations, large earthwork projects, port and terminal operations, and large-scale infrastructure construction. Therefore, it needs to be equipped with rims with high load capacity, high strength and durability, stable structure, and good heat dissipation performance. The rims we provide this time are specially developed and designed for the needs of L260H!

What are the advantages of Volvo L260H with our 27.00-29/3.5 rims?

1. Improve load capacity

The 27.00-29/3.5 rims are suitable for large-size high-load tires, giving it excellent load capacity. It can withstand the continuous operation requirements of the loader under high load conditions, and is particularly suitable for handling ore, large volumes of sand and gravel, and construction waste.

2. Enhanced operation stability

The flange height of 3.5 inches provides additional support to ensure that the tire is not easy to fall off the rim in a high-pressure environment. The wider contact surface and stable structural design effectively reduce the risk of rollover and improve operation safety.

3. Improved durability

Rims made of high-strength steel have excellent impact and wear resistance and are suitable for working in harsh environments. They can effectively resist damage to the rims caused by sharp gravel and high-frequency vibrations in mining areas and construction sites.

4. Optimized power transmission and grip performance

When used with high-performance tires, it provides stronger traction and grip. It is suitable for rugged mining areas, slippery ports and soft earthwork ground.

5. Reduced maintenance costs

The sturdy structure and good heat dissipation performance reduce rim deformation and overheating. Extend the service life of tires and rims, and reduce the frequency and cost of equipment maintenance.

6. Improved operating efficiency

Large-size rims support higher speeds and higher operating efficiency, reducing single operation time. It helps to quickly complete handling operations in large construction sites.

Therefore, our 27.00-29/3.5 rims have been recognized by Volvo for their high load capacity, excellent stability and durability, providing reliable operation support for Volvo L260H, and are particularly suitable for heavy-duty operation scenarios such as mines, quarries and large-scale construction projects.

We not only produce mining vehicle rims, but also have a wide range of applications in construction machinery, forklift rims, industrial rims, agricultural rims and other rim accessories and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. You can send me the rim size you need, tell me your needs and concerns, and we will have a professional technical team to help you answer and realize your ideas.

Our products are of world-class quality.

Post time: Aug-29-2025