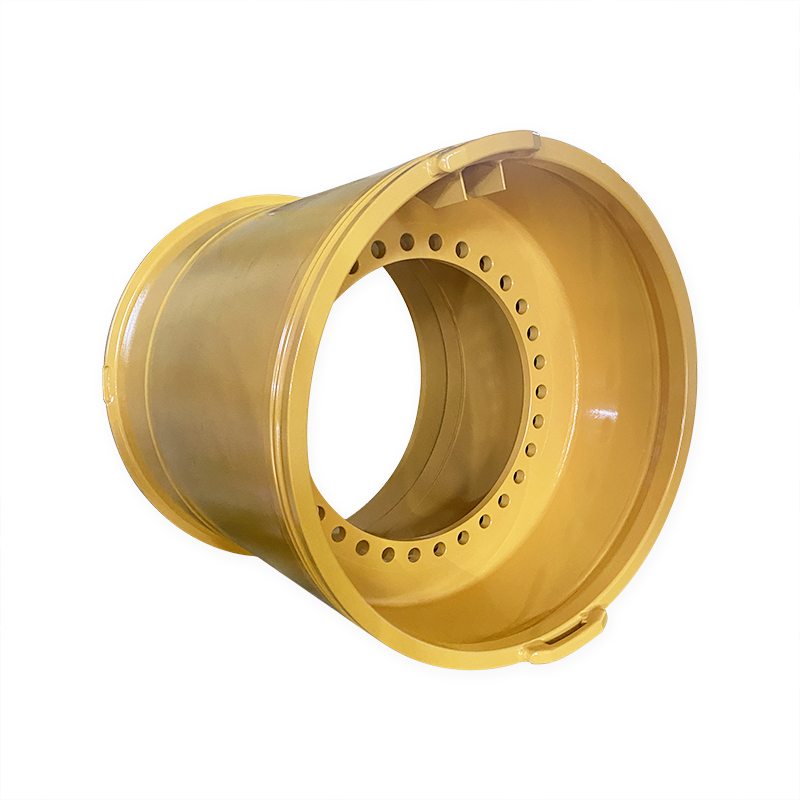

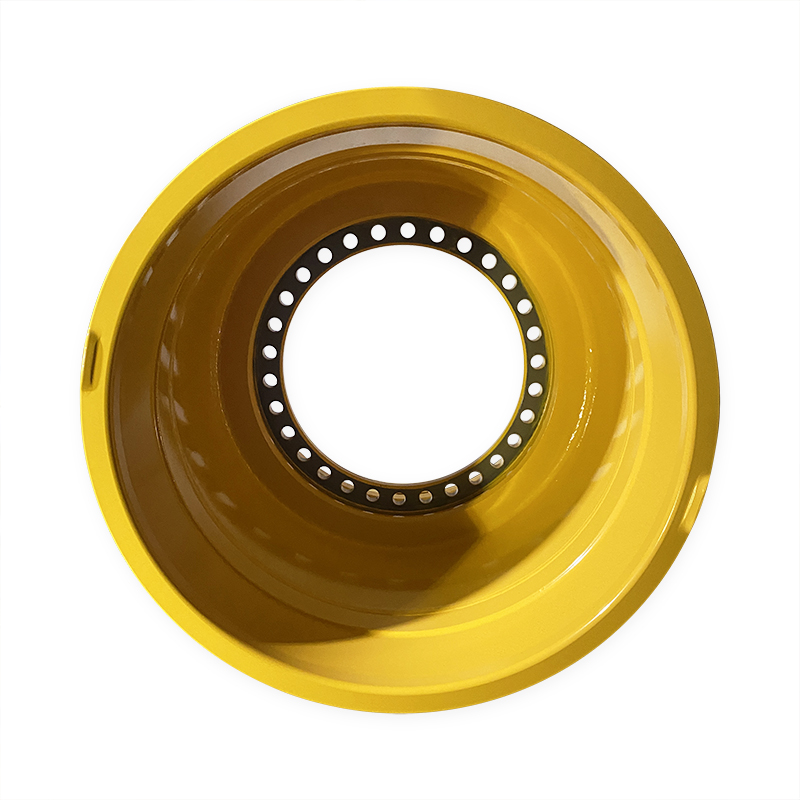

Our company provides 27.00-29/3.5 rims for Volvo L220 wheel loader

The Volvo L220 series wheel loader is a large, high-performance, multi-purpose loader launched by Volvo Construction Equipment. It is widely used in heavy-duty working conditions such as mines, ports, and material yards .

Volvo L220 is widely praised in heavy-load working conditions such as mines, ports and material yards for its outstanding performance, comfort and reliability.

The main advantages include the following:

1. Powerful power and fuel efficient

Equipped with Volvo's self-developed D13J engine, it has stable power output and a maximum power of 367hp (274kW).

Equipped with Volvo OptiShift intelligent shifting system and ECO mode, it can save fuel by up to 10%, taking into account both performance and economy.

2.Excellent production efficiency

The bucket capacity is large (about 5.7\~6.2m³ as standard, and up to 16m³ as optional) to match high productivity.

The responsive hydraulic system provides precise operation, fast cycle times and increased loading efficiency per hour.

With a maximum traction force of 330+kN and a breakout force of 250+kN, heavy-load operations are effortless.

3. Comfortable control and humanized design

Equipped with a ROPS/FOPS safety certified cab, it has a spacious interior and a wide field of vision.

Air suspension seats, automatic air conditioning, and excellent noise control allow you to drive for long periods without feeling tired.

The electronically controlled multi-function handle (joystick) provides smooth and sensitive control and easy operation.

4. Intelligent management system

Equipped with Volvo Co-Pilot smart terminal and CareTrack remote sensing system, it can monitor in real time: fuel consumption/working hours, fault warning, maintenance plan, and can be connected with the scheduling platform to realize digital equipment management.

5. High maintenance convenience

The engine compartment adopts a large-angle flip-over cover to facilitate daily maintenance.

Centralized lubrication system (optional) reduces the number of manual maintenance.

Volvo original parts have a high commonality rate and fast after-sales response.

6. High reliability and durability

The reinforced frame, articulation system and bridge box are impact-resistant and durable.

It is suitable for various working condition tires (such as L3/L5), and a heavy-duty protective cover is optional.

Suitable for high-intensity environments such as continuous work and heavy load handling.

7. Flexible configuration and wide application

Optional: various buckets, quick-change joints, forks, snow plows and other multifunctional accessories

Meet different operating scenarios: mines, ports, mixing stations, material yards, etc.

Under such harsh working conditions and heavy-load operations, Volvo L220 has extremely special requirements for wheel rims. It needs to be equipped with a multi-piece wheel rim that is high-strength and easy to disassemble and assemble to meet the impact of heavy loading in mines and easy to replace and maintain. The surface needs to be specially treated with anti-rust primer, epoxy paint or hot-spray zinc treatment to improve corrosion resistance.

The 27.00-29/3.5 rim we designed can meet these requirements of Volvo L220 .

27.00-29/3.5 is a rim specification used for tires on large engineering machinery (such as mining dump trucks, loaders, etc.).

Most of them are welded from high-strength steel; the five-piece split structure design allows for quick disassembly and assembly, and efficient tire replacement, making it suitable for high-frequency operations in mining areas.

What are the advantages of using 27.00-29/3.5 rims on Volvo L220 wheel loaders?

The Volvo L220 series wheel loaders are equipped with 27.00-29/3.5 rims (matched with corresponding 27.00-29 or 27.00R29 tires) mainly to meet their large load capacity and stability requirements under high-intensity working conditions. The following are the specific advantages of using this specification of rims:

Advantages of using 27.00-29/3.5 rims:

1. Strong carrying capacity

The tires that are compatible with the 27.00-inch wide + 29-inch diameter rims have a higher load index (Load Index), which can meet the operating requirements of high-tonnage loaders such as the L220 (the total machine weight is more than 30 tons, and the bucket capacity is 6-10 cubic meters) under heavy load conditions.

2. Improved tire stability

The 3.5-inch flange height can effectively fix the tire bead, preventing the tire from slipping or shifting under high torque and high lateral force, thereby improving operation safety.

3. Good adaptability to off-road and mining areas

The rim supports the installation of high-pattern and deep-pattern OTR engineering tires, which can improve the Volvo L220's grip and puncture resistance in extreme terrains such as soft ore piles, gravel yards, and slag yards.

4. Reduce the risk of tire derailment

The split structure + 3.5-inch flange can better withstand the high pressure inside the tire and reduce the risk of tire blowout or bead unseating. It is especially suitable for tubeless (TL) tires and has a good sealing effect when combined with the airtight ring.

5. More convenient maintenance

The five-piece split rim is easy to disassemble and assemble on site, which is particularly advantageous in a mining environment where tires are frequently replaced.

In short, the configuration of 27.00-29/3.5 rims can significantly enhance the performance of Volvo L220 in heavy-load complex environments such as mining areas and material yards, and improve: operating efficiency, handling stability, equipment durability, and operational safety.

HYWG is China's No.1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards .

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing . We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: May-23-2025