The rim of a wheel is the part of the wheel used to mount and support the tire. It is also called the wheel rim or the edge of the hub. In daily life, people often use the terms "rim" and "hub" or even "wheel" interchangeably, but technically speaking, they are different parts.

The rim is an important component of the wheel and is directly related to the installation, safety and running performance of the tire . It is a ring-shaped metal structure on the outside of the wheel that is used to install and support the tire and ensure that the tire maintains its shape.

The rim plays a very important role in the wheel :

1. Used to fix the tire: The tire is firmly installed by the structure of the rim (such as flange, slot) to ensure that it will not fall off.

2. Bear the weight of the vehicle: The tires transfer the weight of the vehicle to the ground.

3. Maintain tire shape and air pressure: Make sure your tires are well sealed and not leaking (especially tubeless tires).

4. Connecting the spokes and tires: In the overall wheel structure, the rim is the key to connecting the hub (center) and the tire (outer layer).

The existence of rims is crucial for off-road vehicles. It is not only a connecting component between the tire and the vehicle, but also one of the key links to ensure the safe and efficient operation of the equipment.

Off-highway vehicles (such as mining trucks, loaders, bulldozers, and graders) often operate in extreme environments, with individual wheels potentially bearing tens or even hundreds of tons of weight. The rims they are equipped with must feature high-strength steel construction and superior welding and heat treatment processes to prevent breakage and deformation under impact or heavy loads.

Off-highway vehicles often use tubeless tires, which place extremely high demands on the rim's sealing structure. Deformation or surface defects on the rim can easily lead to air leaks , blowouts , and premature tire wear , reducing the vehicle's service life.

High-quality rims can adapt to more severe working conditions and improve vehicle operating stability . Off-road vehicles often operate in a wide range of environments, including rocky, muddy, and gravel roads , which are subject to high impact loads . Our rims can prevent severe impacts and lateral forces , tires from falling off the rim , rim edge breakage , and unstable shaking during operation , ensuring vehicle safety and preventing major accidents .

We are China's leading off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All our products are designed and manufactured to the highest quality standards .

We have a R&D team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies to maintain our leading position in the industry. We have established a comprehensive after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use.

We have a long-standing reputation for designing and manufacturing high-quality rims for a wide range of off-highway vehicles. Our rims are designed to withstand the severe stresses inherent in mining environments, including heavy loads, dynamic forces, and corrosive elements. By utilizing advanced manufacturing processes and high-strength materials, we ensure maximum fatigue life and reliable performance. We are the original equipment rim supplier in China for renowned brands such as Volvo, Caterpillar, Liebherr, and John Deere.

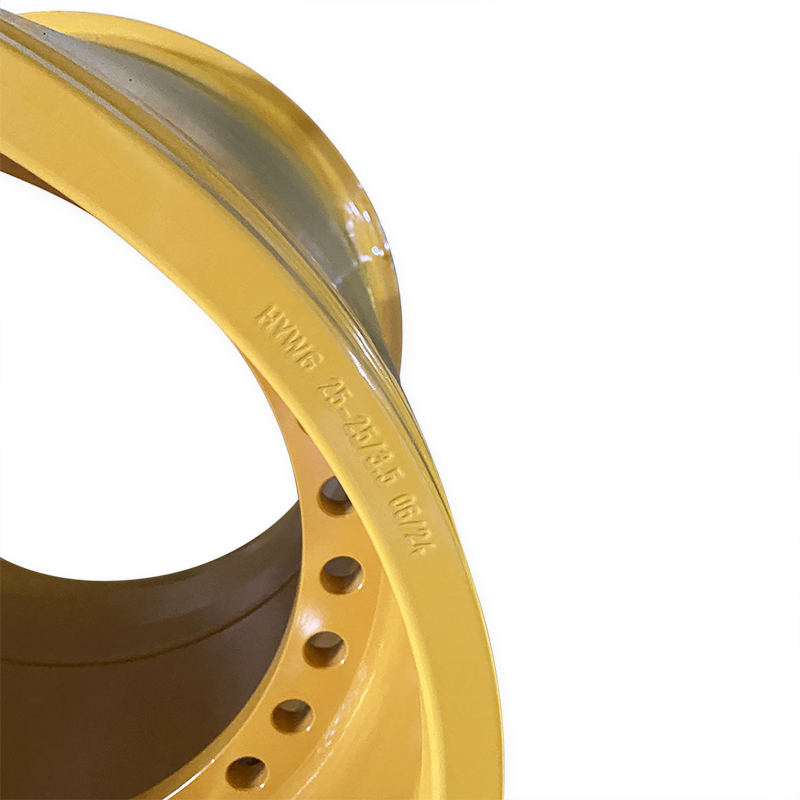

We provide 25.00-25/3.5 5PC rims for large wheel loaders such as Volvo L250.

The Volvo L250 is a large wheel loader that combines powerful power, excellent stability and efficient operating capabilities. It is widely used in harsh environments such as quarries, mines and heavy loading and unloading operations.

The Volvo L250 large wheel loader is widely trusted for its superior performance and strong productivity in heavy-duty operations and extreme working conditions. To perfectly match this high-performance machine, we have specially designed 25.00 - 25/3.5 5PC rims to meet the higher demands placed on rims in high-load and high-frequency working environments.

25.00 - 25/3.5 5PC rim boasts excellent structural strength and precise fit, ensuring a close fit between the tire and rim for stability and reliability during loading, transport, and dumping.

The 5PC (five-piece) design structure, including the main wheel rim, locking ring, flange, side retaining ring and locking ring, effectively simplifies the tire assembly and disassembly process and greatly improves maintenance efficiency. It is particularly suitable for working conditions such as mines and docks that have high requirements for continuous equipment operation.

rims are constructed from high-strength low-alloy structural steel, heat-treated, and coated with an anti-corrosion coating, providing excellent impact and corrosion resistance. They maintain exceptional performance in harsh environments such as mud, gravel, heat, and humidity . The overall structure is optimized , with a balanced center of gravity and strong deformation resistance, effectively reducing the risk of tire derailment or flats, ensuring operational safety. This stability not only enhances equipment reliability but also helps the Volvo L250 achieve higher fuel efficiency and operational efficiency.

Our company has extensive involvement in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. You can send me the rim size you need, tell me your needs and concerns, and we will have a professional technical team to help you answer and realize your ideas.

Our products are of world-class quality.

Post time: Sep-05-2025