Underground mining rims are key load-bearing components specifically designed for underground mining conditions. Their structure and performance are significantly different from those of surface mining rims and ordinary engineering machinery rims.

Underground mining rims are designed for the unique working conditions of underground mines . Underground mines operate in environments with narrow tunnels, small turning radii , slippery surfaces, abundant mud and water, and heavy dust . Continuous, long- term high-load operations are common , ventilation is limited, and the safety requirements for equipment are extremely high . Therefore, the appropriate underground mining rims must be able to operate stably for extended periods within confined spaces , while still meeting the high load and safety risks of the vehicle .

Therefore, the core characteristics of underground mining wheel rims are high load-bearing capacity and high safety margin .

HYWG, as one of the world's top three OTR heavy-duty wheel manufacturers , has more than 20 years of experience in manufacturing mining rims.

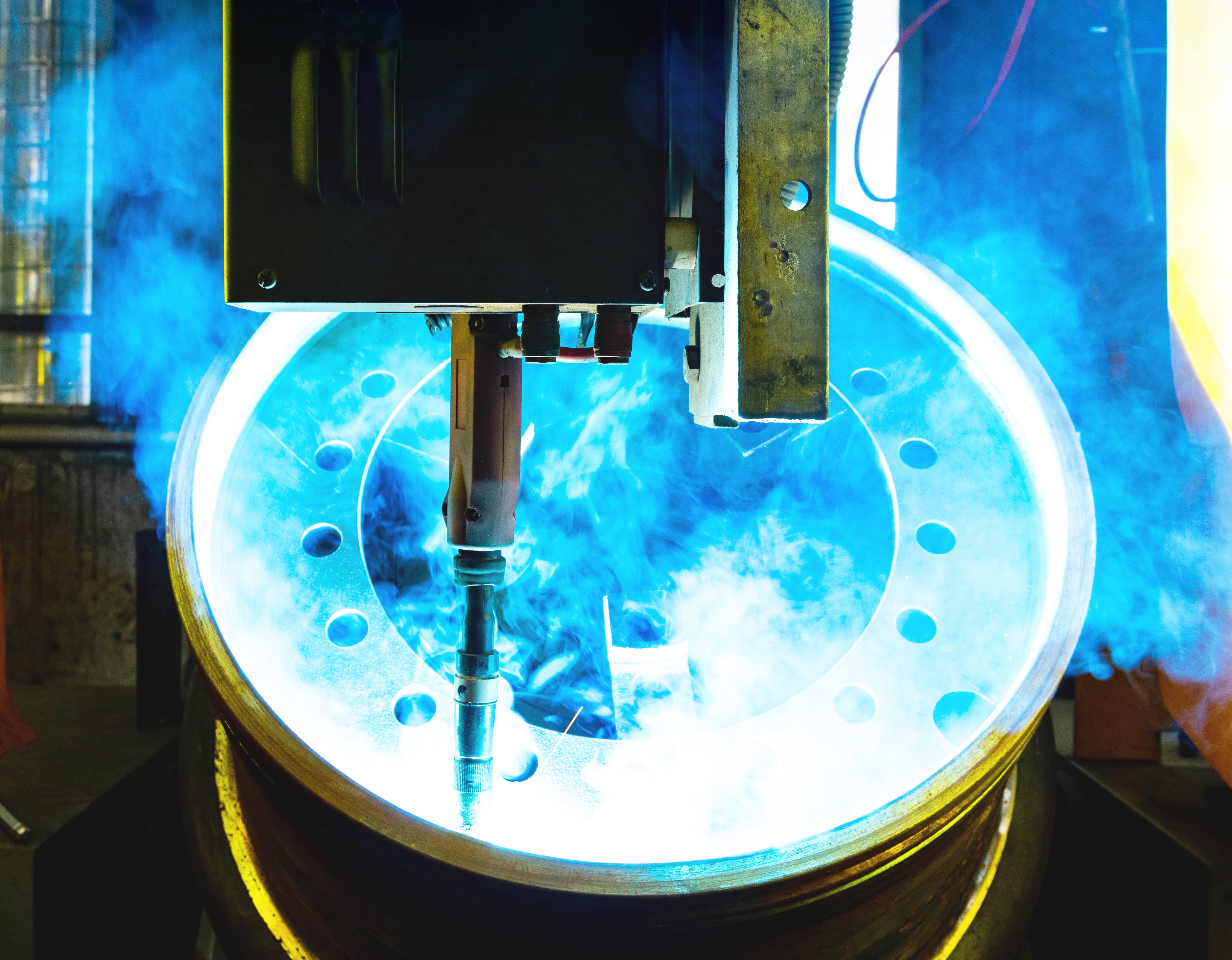

HYWG possesses the capability to independently produce steel profiles for wheel rims, marking a watershed moment in high-end manufacturing capabilities within the OTR wheel rim sector. The advantage it brings goes far beyond simply "making its own materials"; it determines the safety ceiling, consistency, and long-term reliability of the wheel rims from the very beginning.

The safety and lifespan of OTR rims are determined from the source of materials. This ensures that the product surpasses ordinary standard rims in concentricity, fatigue resistance, weld strength, and service life. High-strength, high-quality steel guarantees excellent fatigue and impact resistance.

It possesses a complete industrial chain production from steel to finished wheel rims, including steel rolling, mold design, high-precision forming, automated welding, surface treatment, and finished product inspection. This "one-stop" production model ensures that all products meet uniform high standards, truly realizing full-chain manufacturing and quality control of wheel rims.

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

5.Painting

6. Finished Product

HYWG's mining rims feature a thickened rim base and a locking ring structure , with a design load significantly higher than that of conventional engineering machinery rims . They can withstand the impact loads and eccentric loads of underground mining trucks, loaders, and underground mining cars , preventing rim deformation, cracking, and fatigue failure .

We have a research and development team composed of senior engineers and technical experts who focus on the research and application of innovative technologies. Through precise steel profile design and structural optimization, we improve the overall strength of wheel rims under heavy load conditions . In view of the working environment of underground mining vehicles , we strengthen the wheel rim flange and wheel rim seat area , optimize stress distribution, reduce fatigue concentration , improve the ability to withstand lateral forces and impact loads , and reduce vehicle downtime and maintenance costs during operation.

Underground mines are characterized by high humidity and strong corrosiveness. HYWG rims feature a reinforced sealing groove design , compatible with tubeless (TL) or reinforced inner tube structures . The surface is treated with anti-corrosion coatings , rust-proof sprays, or electrophoretic treatments to extend the rim's service life in humid and corrosive environments .

Excellent customer service is also crucial . A comprehensive after-sales service system can provide timely and efficient technical support and after-sales maintenance, ensuring you have a smooth experience during use.

Underground mining rims are not "general-purpose rims," but rather highly reliable products designed with a systematic approach to underground safe production. They are one of the fundamental components for the safe operation of underground mining vehicles.

The Atlas Copco MT5020 is a mature 50-ton underground mining dump truck specifically designed for underground mining transportation. Its superior load-bearing capacity, reliable power system, and high uptime make it a representative of 50-ton mining trucks.

To enable this high-performance mining truck to achieve superior transportation efficiency under extreme conditions, HYWG, in collaboration with industry-leading technologies, has meticulously crafted a 28.00-33/3.5 mining rim solution for the MT5020, achieving a perfect match between the machine and the rim.

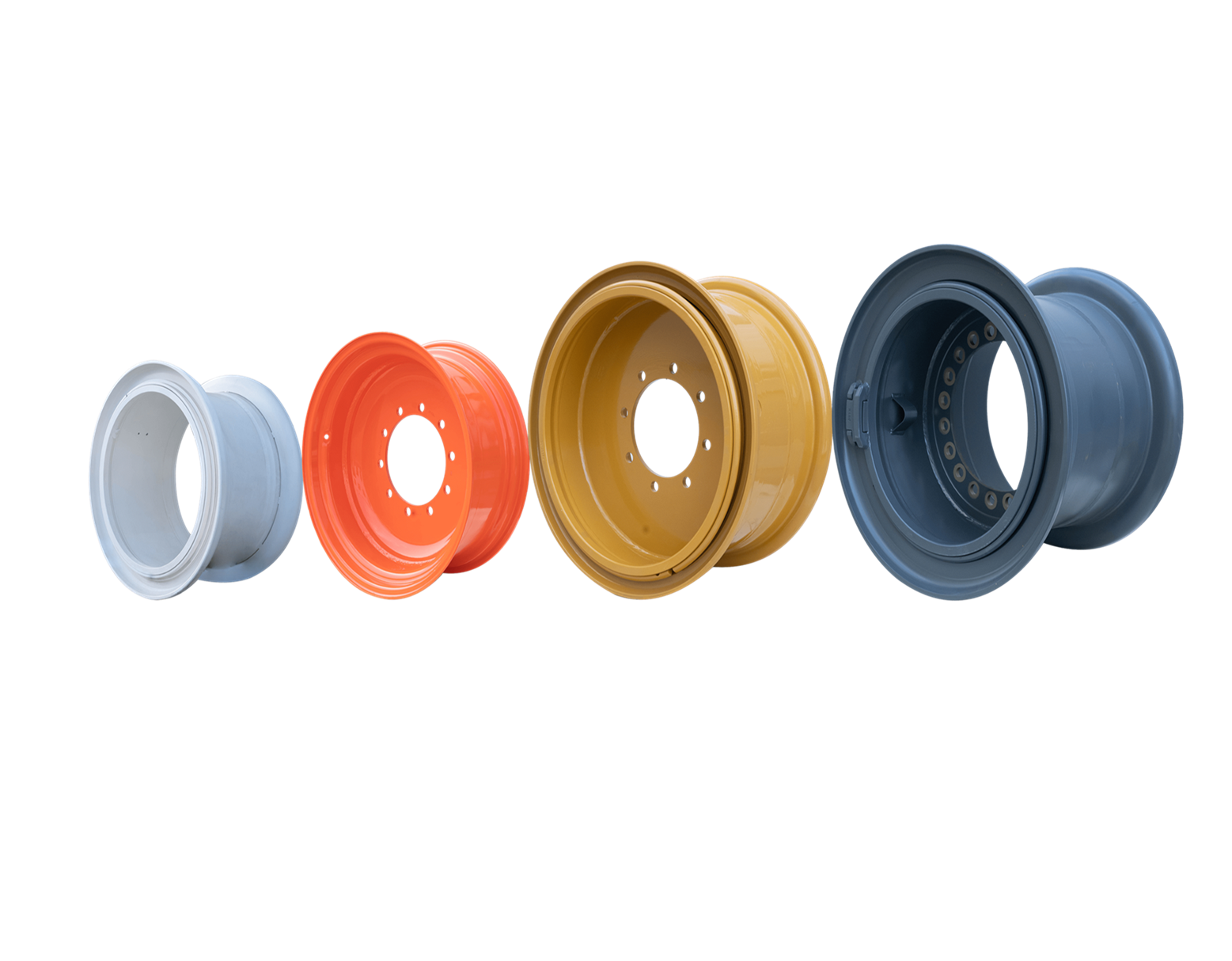

28.00-33/3.5 is a 5PC structure rim for TL tires, commonly used in underground loaders and trucks. The quality of our underground mining rims has been proven. We are able to provide underground mining rims for CAT, Sandvik, Atlas Copo.

Designed specifically for the MT5020 , unlike universal rims, HYWG's 28.00-33/3.5 rims are precisely matched to the tire specifications and load requirements of the MT5020 's operating scenarios . The design is optimized based on the vehicle's powertrain, steering geometry, and road conditions , avoiding safety risks or performance losses caused by rim - ticket mismatch.

This wheel rim size not only meets the mining requirements of high load-bearing capacity, high grip, and stable operation, but also takes into account the working conditions of narrow underground mines and complex road conditions.

Utilizing self-produced high-strength special-purpose steel materials and featuring a self-designed cross-section, it boasts superior static and dynamic load-bearing capacity matched to the MT5020's load and power requirements. Its robust impact resistance and fatigue resistance effectively address harsh environments such as uneven roadways and impacts from gravel . Safety is not an add-on; it's in the rim's DNA.

User feedback indicates that HYWG rims make the MT5020 more stable under conditions such as full load, steep slopes, and muddy conditions, reducing the risk of sideslip and abnormal tire pressure. Compared to universal rims, HYWG rims reduce wear and fatigue damage caused by uneven force distribution. Their high consistency and durable design result in longer maintenance intervals and lower component replacement costs.

We not only provide high-quality rim solutions for the Atlas Copco MT5020, but also have extensive involvement in the fields of construction machinery rims, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

HYWG 's products are exported to more than ten countries, including North America, Europe, Australia, and Russia . With leading manufacturing capabilities, rigorous quality control, and a global service system, we provide customers with reliable wheel rim solutions. We are an original equipment manufacturer (OEM) wheel rim supplier in China for renowned brands such as Volvo, Caterpillar, Liebherr, and John Deere , becoming a trusted partner for OTR ( Original Equipment Manufacturer) users worldwide .

Post time: Jan-19-2026