Mining dump trucks use oversized OTR tires, which are much larger than those on ordinary trucks or construction machinery . These tires are designed to carry extremely heavy loads and operate in rugged mining environments. Tire sizes vary significantly depending on tonnage and vehicle type, but can be broadly categorized as follows:

1.Common tire sizes for small and medium-sized mining dump trucks are: 18.00-25 , 23.5-25 , 26.5-25 , and 29.5R25 . The diameter of these tires is generally around 1.6 to 1.8 meters.

2.Common tire sizes for medium and large mining dump trucks are 27.00-29 , 30.00-51 , and 33.00-51 . The diameter of these tires is generally between 2.2 and 2.8 meters.

3.Extra-large mining dump truck tire dimensions : 36.00R51 , 40.00R57 , 46/90R57 , 53/80R63 , 59/80R63 — these tires have astonishing diameters , reaching 3.5 meters or even 4 meters, taller than a single-story building. An adult standing next to a tire would only reach the center of the rim.

They have extremely high load-bearing capacity to match the loads of heavy mining trucks , and the tread design is deep to resist the cutting and abrasion of rocks and sharp objects common in mining areas.

Oversized OTR (off-road) tires require matching oversized, high-strength dedicated rim systems. This combination is key to enabling mining trucks to withstand loads of tens to hundreds of tons and operate under extreme conditions for extended periods.

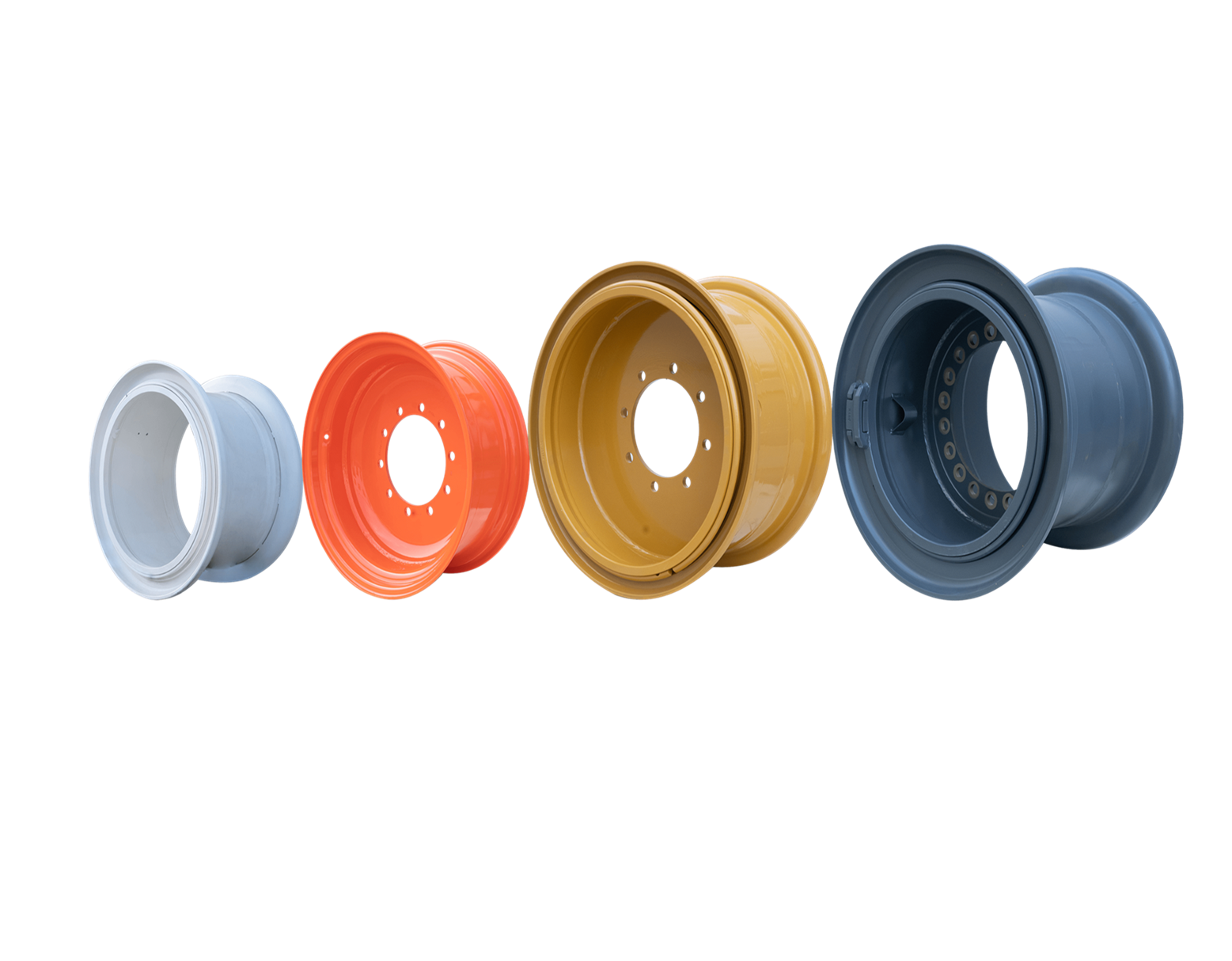

Compared to ordinary truck rims, these mining dump truck rims require high-strength , high-quality steel and feature a multi-piece structure design for easy installation of oversized tires . They possess superior impact and deformation resistance , and are equipped with special locking rings and snap rings to ensure safety even under heavy loads , precisely matching the tires and the overall vehicle load .

As one of the world's top three OTR wheel manufacturers, we have extensive experience in the production and manufacturing of mining vehicle rims. With more than 20 years of experience, HYWG has served hundreds of OEMs worldwide and has long been designing and manufacturing high-quality rims suitable for various off-highway vehicles.

We offer mining rims—19.50-49 / 4.0 multi-piece (5PC) rims—that are compatible with 49-inch extra-large diameter tires, taking into account the structural characteristics and load requirements of the CAT 777.

19.50-49/4.0 rim is 5PC structure rim for TL tire, it’s commonly used by mining dump truck. We are China leading wheel rim manufacturer for dump truck CAT 777.

As one of the most widely used mining dump trucks globally, the CAT 777 plays an irreplaceable role in open-pit mines and large-scale engineering projects due to its excellent carrying capacity and strong adaptability to various working conditions. The matching wheel rims are core components that bear the weight of the entire vehicle and ensure operational safety.

We specialize in the research and development and manufacturing of wheel rims for heavy-duty engineering vehicles and mining equipment, providing professional-grade, large-size, multi-piece mining wheel rim solutions for CAT 777 to ensure stable and efficient operation of the vehicle under the most demanding working conditions.

The 19.50-49 / 4.0 multi-piece rim is designed specifically for mining dump trucks. It consists of multiple components such as rim base, side ring, and locking ring , and meets the requirements of ultra-high load and high impact conditions .

It facilitates the assembly and disassembly of extra-large tires , improves on-site maintenance and replacement efficiency, reduces equipment downtime , and allows for individual component replacement in the event of localized damage, thus reducing overall maintenance costs . Compared to one-piece rims, the multi-piece structure is more suitable for the frequent maintenance needs of mines.

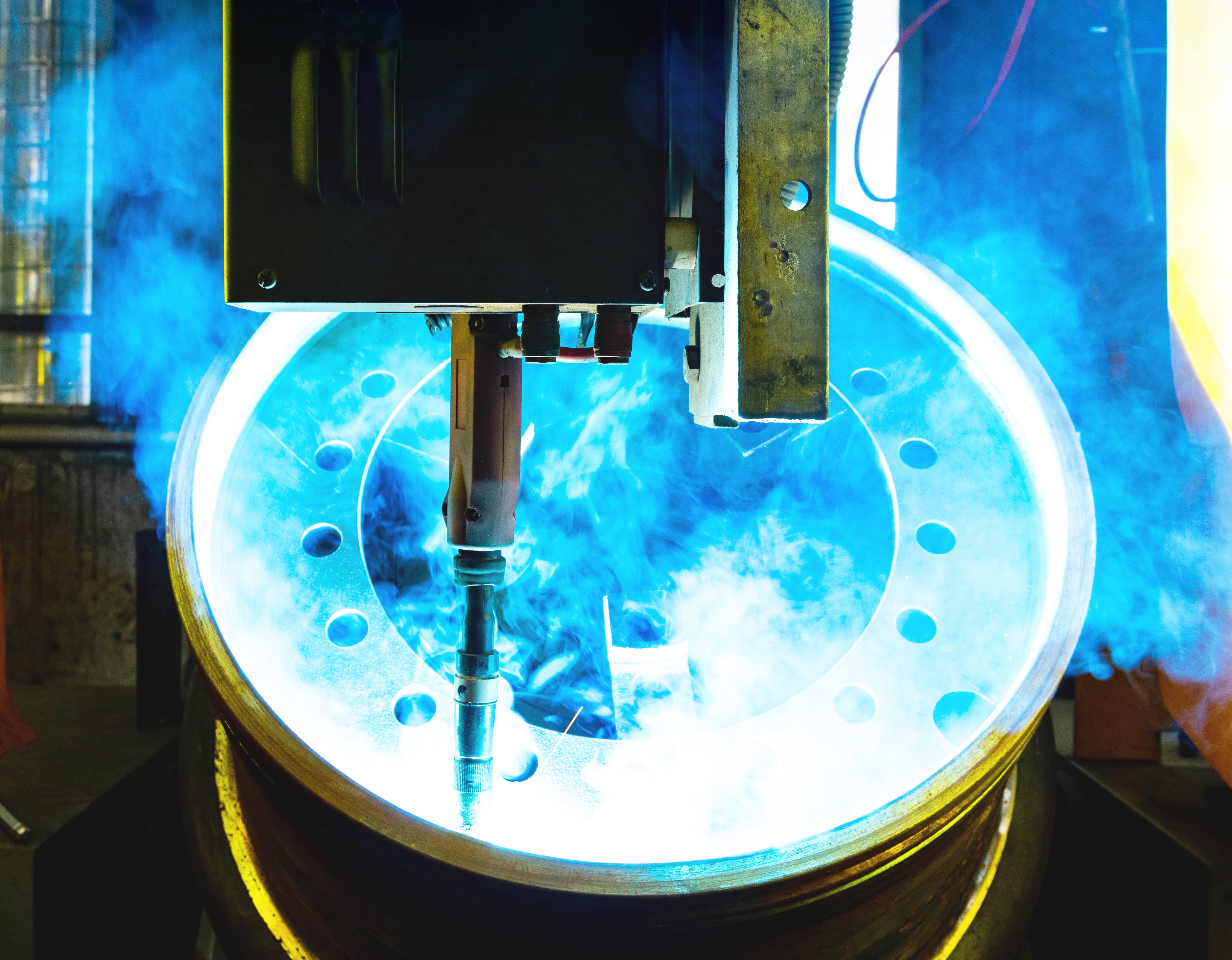

CAT 777 wheels often operate in harsh environments characterized by high temperatures, high loads, high impacts, and dust and rock. Therefore, we select high-strength, high-quality steel and employ multiple processes to strengthen the structural performance of the rims: excellent impact resistance and deformation resistance , outstanding fatigue life , and precision welding and surface treatment processes to effectively prevent cracking and corrosion .

Each wheel rim undergoes rigorous performance and safety testing before leaving the factory to ensure it meets the extreme requirements of mining operations.

In long-term practical applications, it has gained consistent recognition from customers for its high durability, high stability and low failure rate.

.jpg)

We possess a complete industrial chain, encompassing steel rolling, mold design, high-precision forming, automated welding, surface treatment, and finished product inspection. We are one of the few companies in China capable of producing wheel rims from steel to finished product . This "one-stop" production model ensures that all products meet uniformly high standards, truly achieving full-chain manufacturing and quality control for wheel rims.

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

5.Painting

6. Finished Product

HYWG's products not only hold a significant market share in China but are also exported to more than ten mining-developed regions, including North America, Europe, Australia, and Russia. With leading manufacturing capabilities, rigorous quality control, and a global service system, we provide reliable wheel rim solutions for our customers. We are an original equipment manufacturer (OEM) wheel rim supplier in China for renowned brands such as Volvo, Caterpillar, Liebherr, and John Deere.

With its stable quality and excellent service, HYWG has gradually become a trusted partner for mining users worldwide.

We have extensive involvement in the fields of construction machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: Dec-05-2025