What is the main function of a dump truck?

The main function of dump trucks is to efficiently transport and automatically unload bulk materials. They are widely used in construction, mining, infrastructure and other engineering scenarios. Their core functions and roles include:

1. Rapid transportation of bulk materials

Dump trucks are mainly used to transport the following materials over short or medium distances:

Earthwork, sand, gravel, coal, ore;

Construction waste, cement, concrete, etc.

2. Automatically uninstall to improve efficiency

Equipped with a hydraulic lifting device, the cargo box can automatically tilt backward or sideways to unload;

It saves manpower and time, and is particularly suitable for high-frequency unloading occasions (such as mining, tunnel engineering, earthwork, etc.).

3. Strong passing ability

Most are designed for high horsepower and high ground clearance;

It can adapt to adverse road conditions such as mud, gravel, and ramps, and is particularly suitable for operations on unpaved roads and mining areas.

4. Diversified Uses

Different types of dump trucks can adapt to different working environments:

Urban construction sites: small dump trucks are maneuverable and flexible;

Open-pit mines: large rigid or articulated dump trucks with large load capacities;

Infrastructure construction: Medium-sized dump trucks are widely used in road and bridge construction.

There are many common dump truck types and brands, which can be divided into:

1. Ordinary dump truck (road type)

Used for urban and rural road transportation, such as sand, coal, construction waste, etc.

2. Heavy Dump Truck

Specially used in open-pit mines, it has a large body, heavy load capacity and strong structural rigidity.

3. Articulated Dump Truck

It is suitable for complex terrains, such as slippery mud, rugged mining areas, etc., and has flexible turning capabilities.

When performing heavy-load transportation and unloading tasks, dump trucks rely on multiple key parts to work together to ensure performance, safety and efficiency. Among the driving parts, tire rims are very important, directly affecting the load-bearing capacity, grip and passability.

HYWG is China's No.1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies to maintain a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing.

provide many types of wheels for Volvo, Caterpillar, Komatsu, Liebherr, John Deere, Huddig and other well-known brands.

Among them , 17.00-35/3.5 rims are provided for the Komatsu 605-7 rigid mining dump truck.

The Komatsu 605-7 is a rigid mining dump truck manufactured by Komatsu of Japan. It is designed for open-pit mines, large earthmoving projects and heavy-load transportation tasks, with excellent load capacity and reliability.

Its main advantages are:

1. Large load capacity: can easily transport more than 60 tons of ore, coal and other heavy objects;

2. Strong power: Equipped with a powerful diesel engine to cope with steep slopes and heavy loads;

3. Rigid structure: The frame structure is strong and suitable for the rugged road conditions in mining areas;

4. Hydraulic retarder: improves downhill safety and reduces brake system wear;

5. Comfortable cab: shockproof design, with air conditioning to reduce driving fatigue;

6. Easy to maintain: The design focuses on maintenance convenience and supports centralized lubrication.

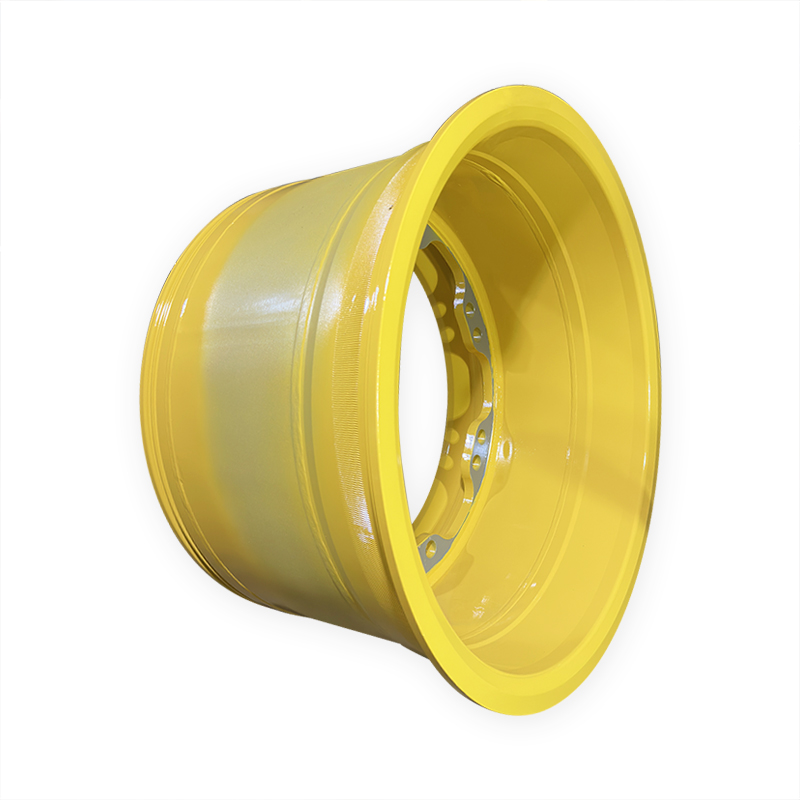

Komatsu 605-7 is a large rigid dump truck widely used in mining and heavy-load conditions. The rims suitable for this model must meet its high load, high strength and high safety requirements . Therefore, we designed a 17.00-35/3.5 5PC rim to match it.

What are the characteristics of the rims that match the Komatsu 605-7 ?

17.00-35/3.5 is made of high-quality steel , suitable for heavy-load conditions , with high load-bearing capacity. It is suitable for heavy-load and harsh occasions such as mines, metallurgy, coal mines, ports, etc., and has good compression resistance and toughness.

The 5-piece structural design facilitates the disassembly and maintenance of large tires. When disassembling and installing tires, only some components need to be detached, saving manpower and time . It is especially suitable for the mine maintenance process using hydraulic tire changers. The multi-piece structure prevents parts from flying out when the tire explodes, improving operation safety.

The surface is treated with special paint , which is corrosion-resistant and salt-alkali-resistant, ensuring long-term service in open-pit mining and extending its lifespan.

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

Our products are of world-class quality.

Post time: May-26-2025

.jpg)

.jpg)