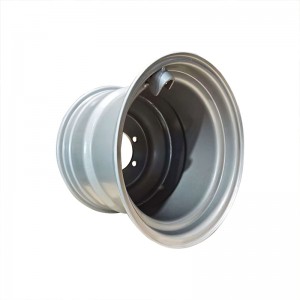

24.00-25/3.0 rim for Mining rim Wheel loader Volvo L120C

Wheel Loader:

Volvo L120C is a classic medium-to-large wheel loader launched by Volvo in the mid-to-late 1990s. It is very popular and still has a large number of units in many parts of the world. It represents Volvo's high standards in hydraulic efficiency, operating comfort and durability. The following is an analysis of the core advantages of L120C:

Main advantages of Volvo L120C

1. Powerful power and balanced performance

Equipped with Volvo TD63KAE turbocharged diesel engine (about 180\~190 horsepower), low speed and high torque output, suitable for heavy-load shoveling and stacking operations.

The engine and hydraulic system are designed in coordination, with good fuel economy and response speed.

2. The hydraulic system is responsive and efficient in operation

The load-sensing hydraulic system (Load-Sensing Hydraulic) can distribute flow according to actual operation needs, avoid energy waste, and make the action smoother and more precise.

Rapid lifting and smooth falling are particularly suitable for continuous operation occasions (such as material transfer, stacking, and loading).

3. Excellent driving comfort (VolvoCab)

ROPS/FOPS safety certified cab, wide field of vision, low noise, good insulation.

Equipped with adjustable suspension seat, ergonomic joystick and dashboard, long-term operation is not easy to fatigue.

4. Durable structure, suitable for harsh working conditions

The frame adopts high-strength steel welded structure, which is impact-resistant and twist-resistant;

The articulated center design is stable, suitable for heavy-duty shoveling and high-frequency operations;

The front and rear axles are heavy-duty drive axles with long service life and high reliability.

5. Easy maintenance and long maintenance cycle

The engine door has a large opening angle and the key parts (filter element, filling port) are reasonably arranged;

Volvo classic model, accessories are highly versatile and easy to purchase;

It was designed as a high-standard model with long maintenance intervals and operators can maintain it by themselves.

6. Excellent shoveling efficiency

The bucket capacity is about 3.0 cubic meters, and the loading efficiency is high;

The center of gravity is reasonably designed, with strong digging force and good transfer stability;

Equipped with automatic horizontal placement and bucket position control to improve loading efficiency.

More Choices

Production Process

1. Billet

4. Finished Product Assembly

2. Hot Rolling

5. Painting

3. Accessories Production

6. Finished Product

Product Inspection

Dial indicator to detect product runout

External micrometer to detect internal micrometer to detect the inner diameter of the center hole

Colorimeter to detect paint color difference

Outside diametermicromete to detect position

Paint film thickness meter to detect paint thickness

Non-destructive testing of product weld quality

Company Strength

Hongyuan Wheel Group(HYWG) was founded in 1996,it is professional manufacturer of rim for all kinds of off-the-road machinery and rim components,such as construction equipment, mining machinery, forklifts,industrial vehicles,agricultural machinery.

HYWG has advanced welding production technology for construction machinery wheels at home and abroad, an engineering wheel coating production line with the international advanced level, and an annual design and production capacity of 300,000 sets,and has a provincial-level wheel experiment center, equipped with various inspection and testing instruments and equipment, which provides a reliable guarantee for ensuring product quality.

Today it has more than 100 milion USD assets,1100 employees,4 manufacturing centers.Our business covers more than 20 countries and regions around the world, and the quality of all products has been recognized by Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD and other global oems.

HYWG will continue to develop and innovate, and continue to serve the customers wholeheartedly to create a brilliant future.

Why Choose Us

Our products include the wheels of all off-road vehicles and their upstream accessories, covering many fields, such as mining, construction machinery, agriculture industrial vehicles, forklifts, etc.

The quality of all products has been recognized by Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD and other global oems.

We have a R&D team composed of senior engineers and technical experts,focusing on the research and application of innovative technologies, and maintaining a leading position in the industry.

We have established a perfect after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure a smooth experience for customers during use.

Certificates

Volvo Certificates

John Deere Supplier Certificates

CAT 6-Sigma Certificates