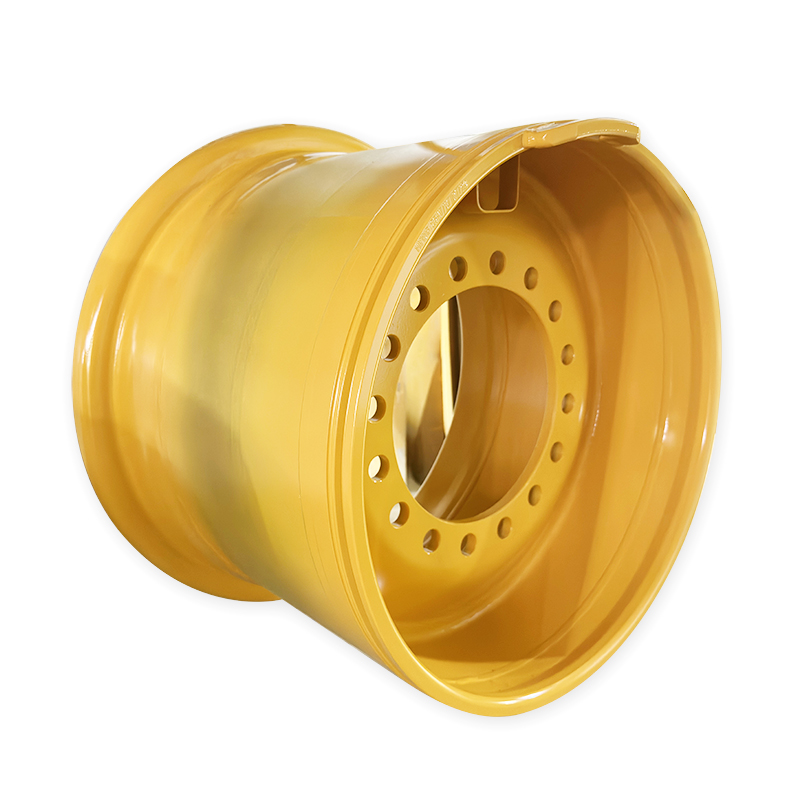

17.00-25/1.7 rim for Construction Equipment Wheel loader

Original Equipment Manufacturer (OEM) wheels, also known as stock wheels, are the wheels that come standard on vehicles when they are first manufactured. The process of making OEM wheels involves several steps, including design, material selection, casting or forging, machining, finishing, and quality control.

Volvo Wheel Loaders typically have features such as:

1. **Design**: OEM wheels start with a design phase where engineers and designers create the wheel's specifications, including dimensions, style, and load-bearing capacity. The design also considers factors such as the vehicle's weight, performance requirements, and aesthetics.

2. **Material Selection**: The choice of material is crucial for the wheel's strength, durability, and weight. Most OEM wheels are made from either aluminum alloy or steel. Aluminum alloy wheels are more common due to their lighter weight and better aesthetics. The specific alloy composition is selected based on the desired properties of the wheel.

3. **Casting or Forging**: There are two primary manufacturing methods for creating OEM wheels: casting and forging.

- **Casting**: In casting, molten aluminum alloy is poured into a mold that has the shape of the wheel. As the alloy cools and solidifies, it takes on the shape of the mold. This method is commonly used for creating intricate designs and is more cost-effective for producing a large number of wheels.

- **Forging**: Forging involves shaping heated aluminum alloy billets using high-pressure presses or hammers. This method typically yields stronger and lighter wheels compared to casting, but it's more expensive and better suited for performance-oriented vehicles.

4. **Machining**: After casting or forging, the wheels go through a machining process to refine their shape, remove excess material, and create features such as spoke designs, lug nut holes, and the mounting surface. Computer-controlled machines ensure precision and consistency in this stage.

5. **Finishing**: The wheels undergo various finishing processes to improve their appearance and protect them from corrosion. This includes painting, powder coating, or applying a clear protective layer. Some wheels might also be polished or machined to create specific surface textures.

6. **Quality Control**: Throughout the manufacturing process, strict quality control measures are in place to ensure that the wheels meet safety, performance, and aesthetic standards. This includes testing for structural integrity, balance, dimensions, and surface finish.

7. **Testing**: Once the wheels are manufactured and finished, they are subjected to various tests such as radial and lateral fatigue testing, impact testing, and stress testing. These tests help verify the wheels' strength and durability under different conditions.

8. **Packaging and Distribution**: After passing quality control and testing, the wheels are packaged and distributed to automotive assembly plants for installation on new vehicles. They might also be available as replacement parts for aftermarket use.

Overall, the process of making OEM wheels is a combination of engineering, material science, precision machining, and quality control to ensure that the wheels meet safety, performance, and aesthetic standards while complementing the vehicle's design and functionality.

More Choices

| Wheel loader | 14.00-25 |

| Wheel loader | 17.00-25 |

| Wheel loader | 19.50-25 |

| Wheel loader | 22.00-25 |

| Wheel loader | 24.00-25 |

| Wheel loader | 25.00-25 |

| Wheel loader | 24.00-29 |

| Wheel loader | 25.00-29 |

| Wheel loader | 27.00-29 |

| Wheel loader | DW25x28 |