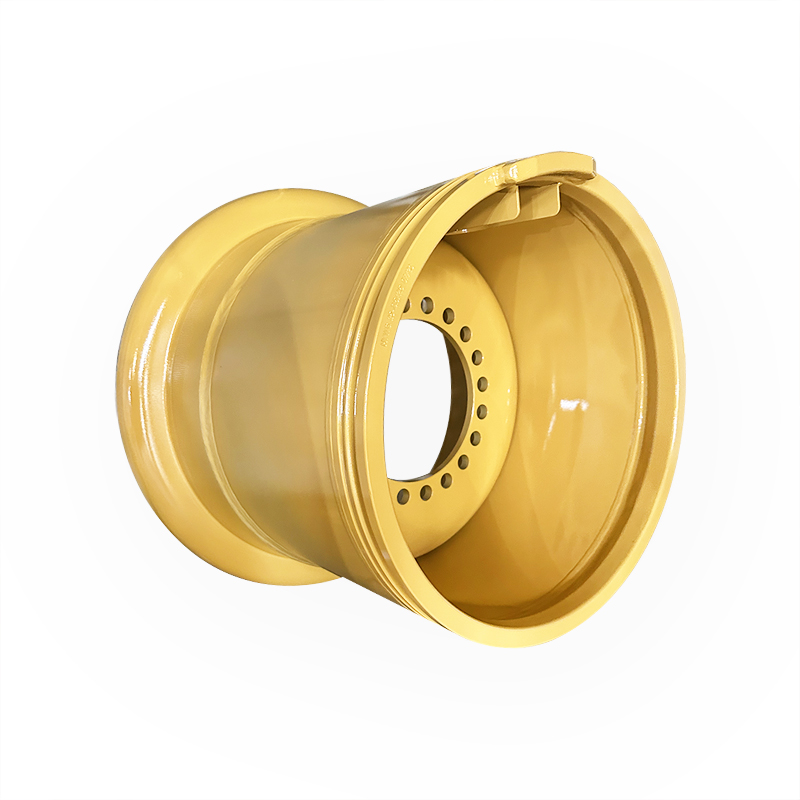

What is a split rim?

The split rim is a rim structure composed of two or more independent parts, and is widely used in heavy equipment such as construction machinery, mining vehicles, forklifts, large trailers and military vehicles.

Common split rims generally consist of the following parts:

1. Rim body : the main structure that supports the tire and bears the tire internal pressure and vehicle load.

2. Locking bead : fix and lock the bead to prevent the tire from falling off.

3. Side ring : fixes the outer tire edge to assist installation and maintain tire stability.

4. Flange : (Some types) Strengthen the rim edge structure, sometimes integrated with the side ring.

The split rims have the following main features:

1. Easy to install and remove tires. Tires can be replaced without a tire press, especially suitable for large-size tires.

2. Suitable for high pressure/heavy load environment and can better withstand the high load of large mining vehicles and engineering equipment.

3. Replaceable parts When a part is damaged, it can be replaced separately, saving maintenance costs.

The split rim is more convenient during installation and removal, but we still need to pay attention to professional operation during the installation process . If it is not installed properly, the lock ring may pop out, posing a safety hazard.

High precision is required for alignment and press-fitting, especially during the inflation process, when it is necessary to check step by step whether the structure is fully engaged.

HYWG is China's No.1 off-road wheel designer and manufacturer, and a world-leading expert in rim component design and manufacturing. All products are designed and produced according to the highest quality standards.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, John Deere, and JCB.

We specialize in the production of 3-PC and 5-PC rims, which are widely used in construction machinery, mining vehicles, industrial vehicles, forklifts and other heavy equipment. Our 19.50-25/2.5 5PC rims are used on CAT 950 wheel loaders.

The reason why the CAT 950 wheel loader uses five-piece rims is mainly due to comprehensive considerations of safety, maintainability and adaptability to heavy-load conditions.

CAT 950 is usually equipped with 23.5R25 or 20.5R25 heavy-duty tires, which cannot be installed efficiently with ordinary one-piece rims. The five-piece rim structure can be easily disassembled and assembled, making it easy to quickly change tires on site.

When a part of the rim is damaged (such as the lock ring or side ring), it can be replaced individually without replacing the entire rim, reducing maintenance costs.

CAT 950 is mostly used in high-intensity working environments such as mines, material yards, and construction sites, where the tire internal pressure is high and the load is heavy. The five-piece rim structure has high strength and can better withstand the impact and pressure under these working conditions. At the same time, the multi-section structure can evenly bear the pressure, avoiding safety accidents such as ring or tire blowout caused by uneven force on the rim structure during inflation or operation.

Therefore, choosing a five-piece rim can help you cope with heavy-load operating environments more safely and efficiently, improve operational reliability and reduce maintenance costs.

Why does the CAT 950 wheel loader use 19.50-25/2.5 rims?

The CAT® 950 wheel loader uses 19.50-25/2.5 rims, mainly for comprehensive considerations of performance matching, safety, durability and operating efficiency.

19.50: refers to the width of the rim (inches), corresponding to wider tires; 25: refers to the diameter of the rim (inches), matching 25-inch tires; 2.5: refers to the flange height of the rim or the type of rim structure (usually used to identify split rims).

This size of rim is suitable for large-size, heavy-load engineering tires such as 23.5R25 and 23.5-25, ensuring that the CAT950's total weight (nearly 19 tons) and high-load conditions are met.

In high-intensity scenarios such as construction, quarrying, and material yards, the rims must be matched with engineering tires that have strong compression and deformation resistance. The 19.50-25/2.5 rims are designed for this heavy load and high stability requirements .

CAT950 is usually used to shovel high-density materials such as sand, coal, and minerals, which places high load-bearing and impact resistance requirements on tires and rims.

The 19.50-25/2.5 wheel rim that matches CAT950 is usually a five-piece split rim, which has the following technical advantages: easy tire replacement and maintenance; strong anti-deformation ability; suitable for harsh working conditions; reduces downtime when changing tires and improves equipment attendance rate.

In short, the CAT950 loader uses 19.50-25/2.5 rims to achieve the best match between the tire and the vehicle under medium and large working conditions, ensuring its load-bearing capacity, operational stability, safety performance and convenience of tire replacement and maintenance.

We have a research and development team composed of senior engineers and technical experts, focusing on the research and application of innovative technologies, and maintaining a leading position in the industry. We have established a complete after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure that customers have a smooth experience during use. We have more than 20 years of experience in wheel manufacturing. We are the original rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, John Deere, and JCB.

Our company is widely involved in the fields of engineering machinery, mining rims, forklift rims, industrial rims, agricultural rims, other rim components and tires.

The following are the various sizes of rims that our company can produce in different fields:

Engineering machinery size:

| 8.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 10.00-25 |

| 11.25-25 | 12.00-25 | 13.00-25 | 14.00-25 | 17.00-25 | 19.50-25 | 22.00-25 |

| 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 | 13.00-33 |

Mine rim size:

| 22.00-25 | 24.00-25 | 25.00-25 | 36.00-25 | 24.00-29 | 25.00-29 | 27.00-29 |

| 28.00-33 | 16.00-34 | 15.00-35 | 17.00-35 | 19.50-49 | 24.00-51 | 40.00-51 |

| 29.00-57 | 32.00-57 | 41.00-63 | 44.00-63 |

Forklift wheel rim size:

| 3.00-8 | 4.33-8 | 4.00-9 | 6.00-9 | 5.00-10 | 6.50-10 | 5.00-12 |

| 8.00-12 | 4.50-15 | 5.50-15 | 6.50-15 | 7.00-15 | 8.00-15 | 9.75-15 |

| 11.00-15 | 11.25-25 | 13.00-25 | 13.00-33 |

Industrial vehicle rim dimensions:

| 7.00-20 | 7.50-20 | 8.50-20 | 10.00-20 | 14.00-20 | 10.00-24 | 7.00x12 |

| 7.00x15 | 14x25 | 8.25x16.5 | 9.75x16.5 | 16x17 | 13x15.5 | 9x15.3 |

| 9x18 | 11x18 | 13x24 | 14x24 | DW14x24 | DW15x24 | 16x26 |

| DW25x26 | W14x28 | 15x28 | DW25x28 |

Agricultural machinery wheel rim size:

| 5.00x16 | 5.5x16 | 6.00-16 | 9x15.3 | 8LBx15 | 10LBx15 | 13x15.5 |

| 8.25x16.5 | 9.75x16.5 | 9x18 | 11x18 | W8x18 | W9x18 | 5.50x20 |

| W7x20 | W11x20 | W10x24 | W12x24 | 15x24 | 18x24 | DW18Lx24 |

| DW16x26 | DW20x26 | W10x28 | 14x28 | DW15x28 | DW25x28 | W14x30 |

| DW16x34 | W10x38 | DW16x38 | W8x42 | DD18Lx42 | DW23Bx42 | W8x44 |

| W13x46 | 10x48 | W12x48 | 15x10 | 16x5.5 | 16x6.0 |

We have more than 20 years of experience in wheel manufacturing. The quality of all our products has been recognized by global OEMs such as Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD, etc. Our products have world-class quality.

Post time: Aug-22-2025