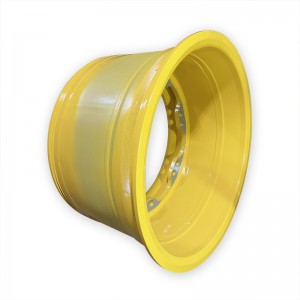

22.00-25/3.0 rim for Mining Underground mining SANDVIK

22.00-25/3.0 is 5PC structure rim for TL tire, it's commonly used by Underground loader and truck. Our quality of underground mining rims have been proven.

Here are the key features and characteristics of a Komatsu wheel loader:

Rims for underground mining vehicles need to be rugged, durable, and capable of withstanding the demanding and harsh conditions of the mining environment. The rims used for these vehicles are designed to provide stability, load-bearing capacity, and resistance to impacts, debris, and rough terrain. Some key considerations for rims used in underground mining vehicles include:

1. **Heavy-Duty Construction:** Rims for underground mining vehicles are typically made from high-strength materials, such as steel or specialized alloys, to handle heavy loads and impacts.

2. **Bead Locking Mechanisms:** Bead locking mechanisms are important to ensure that the tires remain securely attached to the rims, even when operating at low tire pressures or on uneven surfaces.

3. **Reinforced Design:** Rims may feature reinforced areas around the bead seat and valve stem to prevent damage and air leakage.

4. **Corrosion Resistance:** Underground mining environments can be corrosive due to exposure to various chemicals and minerals. Rims designed for these conditions often have protective coatings or treatments to prevent corrosion.

5. **Heat Dissipation:** Some rims are designed with features that promote heat dissipation, helping to prevent overheating of the tires during prolonged operation.

6. **Bolt Patterns and Sizing:** Rims are designed to match specific bolt patterns and tire sizes for different mining vehicles. Proper fitment is crucial for safety and performance.

7. **Ease of Maintenance:** Mining rims may be designed with features that make it easier to replace tires and perform routine inspections and repairs.

8. **Customization:** Depending on the manufacturer and specific mining operation requirements, there may be options for customization, such as different rim designs or sizes.

9. **Compatibility with Tire Types:** The type of tire used in underground mining vehicles (solid tires, foam-filled tires, pneumatic tires, etc.) can impact the design and compatibility of the rims.

Safety is paramount in the mining industry, so it's essential for mining companies to work closely with reputable manufacturers or suppliers that specialize in providing rims specifically designed for underground mining vehicles. These specialized rims are crucial for maintaining the stability, safety, and efficiency of the mining operations.

More Choices

| Underground mining | 10.00-24 |

| Underground mining | 10.00-25 |

| Underground mining | 19.50-25 |

| Underground mining | 22.00-25 |

| Underground mining | 24.00-25 |

| Underground mining | 25.00-25 |

| Underground mining | 25.00-29 |

| Underground mining | 27.00-29 |

| Underground mining | 28.00-33 |