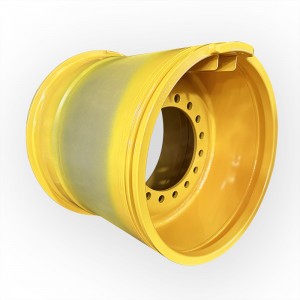

7.50V-20 rim for Industrial rim swamp excavator FOREMOST

Swamp excavator

The operating conditions of Foremost swamp excavators place extremely high demands on their wheel rims. These rims are not traditional tire rims, but rather key components of the track undercarriage, designed to withstand the extremely complex and harsh swamp environment.

The swamp excavator's operating environment is filled with mud, water, plant debris, and sand, requiring the wheel rims to possess the following special properties:

1. Extremely strong sealing:

Sand and moisture from the swamp can intrude into the bearings and seals within the wheel rim, causing increased wear and lubrication failure. The wheel rims must feature a double or multiple conical oil seal design to prevent internal lubrication oil leakage while also preventing external mud and water intrusion. The seal material and design must be extremely durable to resist corrosion and wear.

2. Excellent corrosion resistance:

Prolonged immersion in water and mud, especially seawater or wetlands containing chemicals, can accelerate corrosion of the wheel rim's metal components. The wheel rims must be made of high-quality alloy steel and undergo a special surface treatment or coating to enhance rust and corrosion resistance. 3. High Strength and Wear Resistance:

Soft ground provides insufficient support, resulting in uneven force distribution during movement and operation of the track undercarriage, forcing the wheel rims to withstand significant impact and torque. Furthermore, mud and sand on the track acts as an abrasive, accelerating wear on the wheel rim surface. Therefore, the wheel rims must be made of high-strength steel that has been induction hardened or heat-treated to ensure a hard and wear-resistant surface, while also possessing internal toughness to resist cracking.

4. Optimized Profile Design:

Mud and debris can easily become lodged between the wheel rim and the track, causing additional resistance and even damaging components. The wheel rim profile must be optimized to effectively drain mud and debris during operation, reducing binding and excessive wear. Additionally, some designs utilize double-sided flanges to better guide the track and prevent derailment on soft ground.

5. Low Friction and Excellent Heat Dissipation:

Continuous heavy loads and high-load operation can cause heat to build up inside the wheel rim bearings. Poor heat dissipation can affect lubricant performance and accelerate component aging. The wheel rim bearings must feature a low-friction design and maintain good lubrication to prevent failure due to overheating during extended operation.

In summary, the operating conditions of the Foremost swamp excavator require its wheel rims to be not only as durable and robust as standard excavator components, but also to possess excellent sealing and corrosion resistance to withstand the unique wetland and muddy environment. These specialized properties are crucial to ensuring stable and reliable operation of the equipment under these extreme conditions.

Production Process

1. Billet

4. Finished Product Assembly

2. Hot Rolling

5. Painting

3. Accessories Production

6. Finished Product

Product Inspection

Dial indicator to detect product runout

External micrometer to detect internal micrometer to detect the inner diameter of the center hole

Colorimeter to detect paint color difference

Outside diametermicromete to detect position

Paint film thickness meter to detect paint thickness

Non-destructive testing of product weld quality

Company Strength

Hongyuan Wheel Group(HYWG) was founded in 1996,it is professional manufacturer of rim for all kinds of off-the-road machinery and rim components,such as construction equipment, mining machinery, forklifts,industrial vehicles,agricultural machinery.

HYWG has advanced welding production technology for construction machinery wheels at home and abroad, an engineering wheel coating production line with the international advanced level, and an annual design and production capacity of 300,000 sets,and has a provincial-level wheel experiment center, equipped with various inspection and testing instruments and equipment, which provides a reliable guarantee for ensuring product quality.

Today it has more than 100 milion USD assets,1100 employees,4 manufacturing centers.Our business covers more than 20 countries and regions around the world, and the quality of all products has been recognized by Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD and other global oems.

HYWG will continue to develop and innovate, and continue to serve the customers wholeheartedly to create a brilliant future.

Why Choose Us

Our products include the wheels of all off-road vehicles and their upstream accessories, covering many fields, such as mining, construction machinery, agriculture industrial vehicles, forklifts, etc.

The quality of all products has been recognized by Caterpillar, Volvo, Liebherr, Doosan, John Deere, Linde, BYD and other global oems.

We have a R&D team composed of senior engineers and technical experts,focusing on the research and application of innovative technologies, and maintaining a leading position in the industry.

We have established a perfect after-sales service system to provide timely and efficient technical support and after-sales maintenance to ensure a smooth experience for customers during use.

Certificates

Volvo Certificates

John Deere Supplier Certificates

CAT 6-Sigma Certificates