OTR wheels refer to heavy-duty wheel systems used on off-highway vehicles, primarily serving heavy equipment in mining, construction, ports, forestry, military, and agriculture.

These wheels must be able to withstand high loads, impacts, and torques in extreme environments, and therefore have clear structural classifications. Wheels are typically made of high-strength steel and are suitable for heavy equipment such as mining dump trucks (rigid and articulated) , loaders, graders, bulldozers , scrapers, underground mining trucks , forklifts, and port tractors .

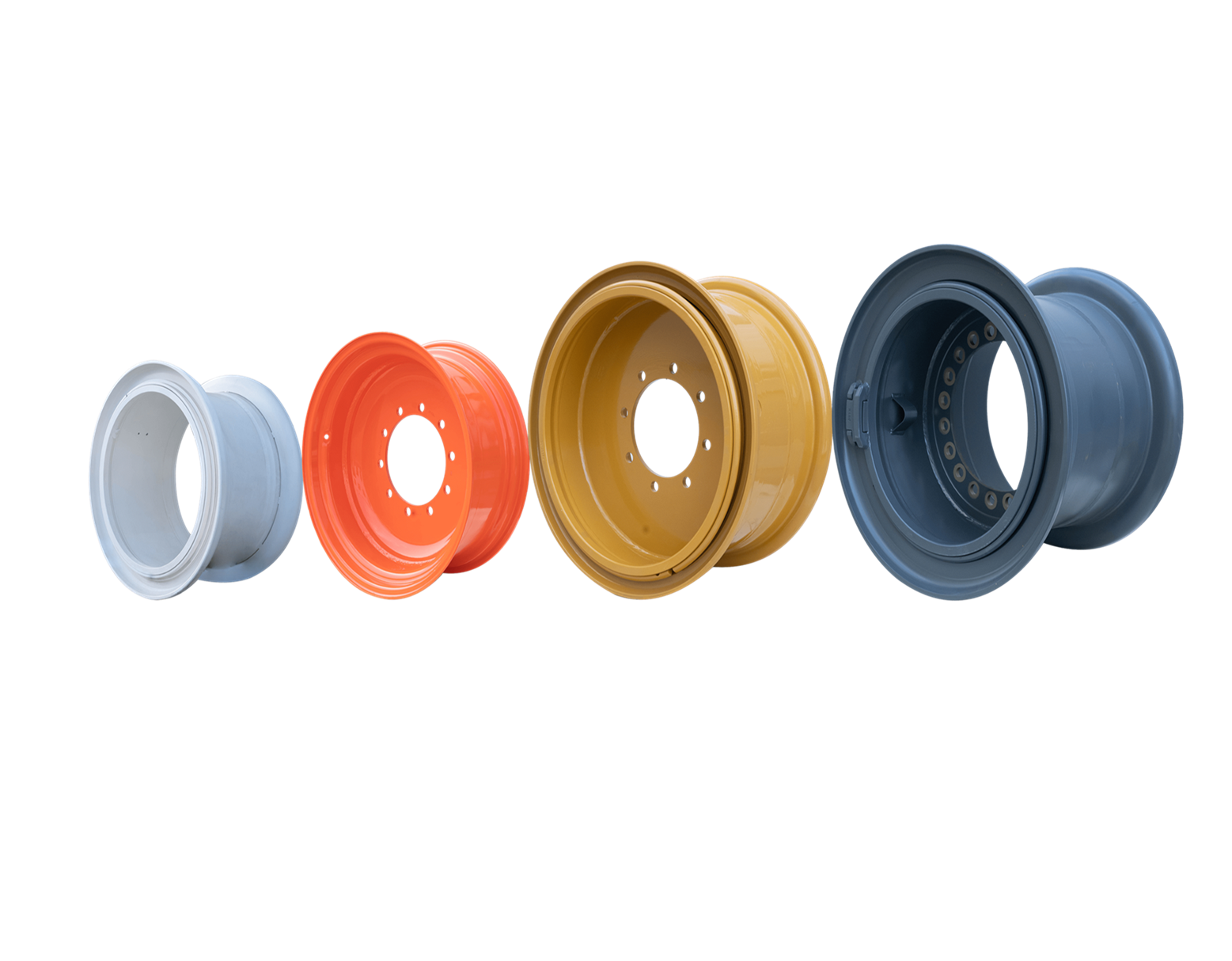

OTR wheels can be classified into the following three types based on their structure :

1. One-piece wheel : The wheel disc and rim are formed as one piece, usually by welding or forging . It is suitable for small loaders, graders, and some agricultural machinery . It has a simple structure, low cost, and is easy to install .

The W15Lx24 rims we provide for JCB backhoe loaders leverage these advantages of one-piece construction to improve overall machine performance, extend tire life, and ensure operational safety.

The one-piece rim is manufactured from a single piece of steel through rolling, welding, and forming in one operation, without any detachable parts such as separate locking rings or retaining rings. In the frequent loading, digging, and transporting operations of backhoe loaders, the rims must constantly withstand impacts and torques from the ground. The one-piece structure effectively prevents rim deformation or cracking.

The one-piece rim boasts excellent structural sealing with no mechanical seams, resulting in stable airtightness and reducing the likelihood of air leaks. Backhoe loaders often operate in muddy, gravelly, and heavy-duty conditions; air leaks can lead to insufficient tire pressure, affecting traction and fuel consumption. The one-piece structure reduces maintenance frequency, maintains stable tire pressure, and thus improves vehicle reliability.

Meanwhile, it has low maintenance costs and is safer to use: there is no need to frequently disassemble and reassemble the lock ring or clip ring, reducing manual maintenance, installation errors, and safety hazards.

One-piece W15L×24 rims are typically designed as tubeless. Compared to traditional tubed tires, tubeless systems offer several advantages: faster heat dissipation and smoother ride; slower air leakage after a puncture and easier repair; easier maintenance and longer lifespan.

For JCB, this will further improve the stability and durability of the equipment in complex construction site environments.

2、Split-type wheels consist of multiple parts, including the rim base, locking ring, and side rings. They are suitable for heavy vehicles such as construction machinery, mining trucks, and forklifts . Such rims have strong load-bearing capacity and are easy to maintain.

The classic CAT AD45 underground mining vehicle uses HYWG's 25.00-29/3.5 5-piece rims.

In underground mining environments, the CAT AD45 needs to operate for extended periods in narrow, rugged, slippery, and high-impact tunnels . The vehicle bears extremely high loads, requiring wheel rims with exceptional strength, ease of assembly and disassembly, and safety features.

This is precisely why we offer the 5-piece 25.00 - 29/3.5 rim as the ideal configuration for the CAT AD45 .

This rim is specially designed for large OTR (Off-The-Road) mining tires, maintaining air tightness and structural strength under extreme loads while facilitating quick disassembly and maintenance.

Underground mining vehicles require frequent tire changes due to limited operating space. The 5-piece design allows for tire removal and installation without moving the entire wheel by separating the locking ring and seat ring . Compared to one-piece or two-piece designs, maintenance time can be reduced by 30%–50%, significantly improving vehicle uptime. For high-utilization mining vehicles like the AD45, this translates to lower downtime costs and higher production efficiency.

Underground mine roads are rugged and subject to severe impacts, with the total vehicle weight (including load) exceeding 90 tons. Large-diameter 25.00-29/3.5 rims can be matched with high-load-bearing, thickened bead tires. The five-piece structure ensures more even load distribution, with each metal rim component bearing stress independently, significantly reducing stress concentration on the main rim. It is more impact-resistant, more fatigue-resistant, and has a service life more than 30% longer than one-piece rims.

When paired with tires of size 25.00-29, the 5-piece construction provides the necessary structural strength to withstand these high loads.

The overall structure can withstand vertical loads and lateral impacts of hundreds of tons, making it very suitable for the heavy-duty mining operation environment of the AD45 .

3. Split rims refer to rim structures composed of two rim halves, divided into left and right halves along the diameter of the rim, and connected together by bolts or flanges to form a complete rim. This structure is typically used for: extra-wide tires or special OTR tires (such as the front wheels of large graders or articulated dump trucks); and equipment that requires tires to be installed and removed from both sides, because the tire's outer diameter is large and the bead is rigid, making it impossible to install or remove from one side.

HYWG is a leading global OTR rim manufacturer. With over two decades of experience, we have served hundreds of OEMs worldwide. We have long designed and manufactured high-quality rims suitable for various off-highway vehicles. Our R&D team, comprised of senior engineers and technical experts, focuses on the research and application of innovative technologies, maintaining our leading position in the industry. We have established a comprehensive after-sales service system, providing timely and efficient technical support and maintenance. Every step of the rim manufacturing process strictly adheres to high-standard quality inspection procedures, ensuring that every rim meets international quality standards and customer requirements.

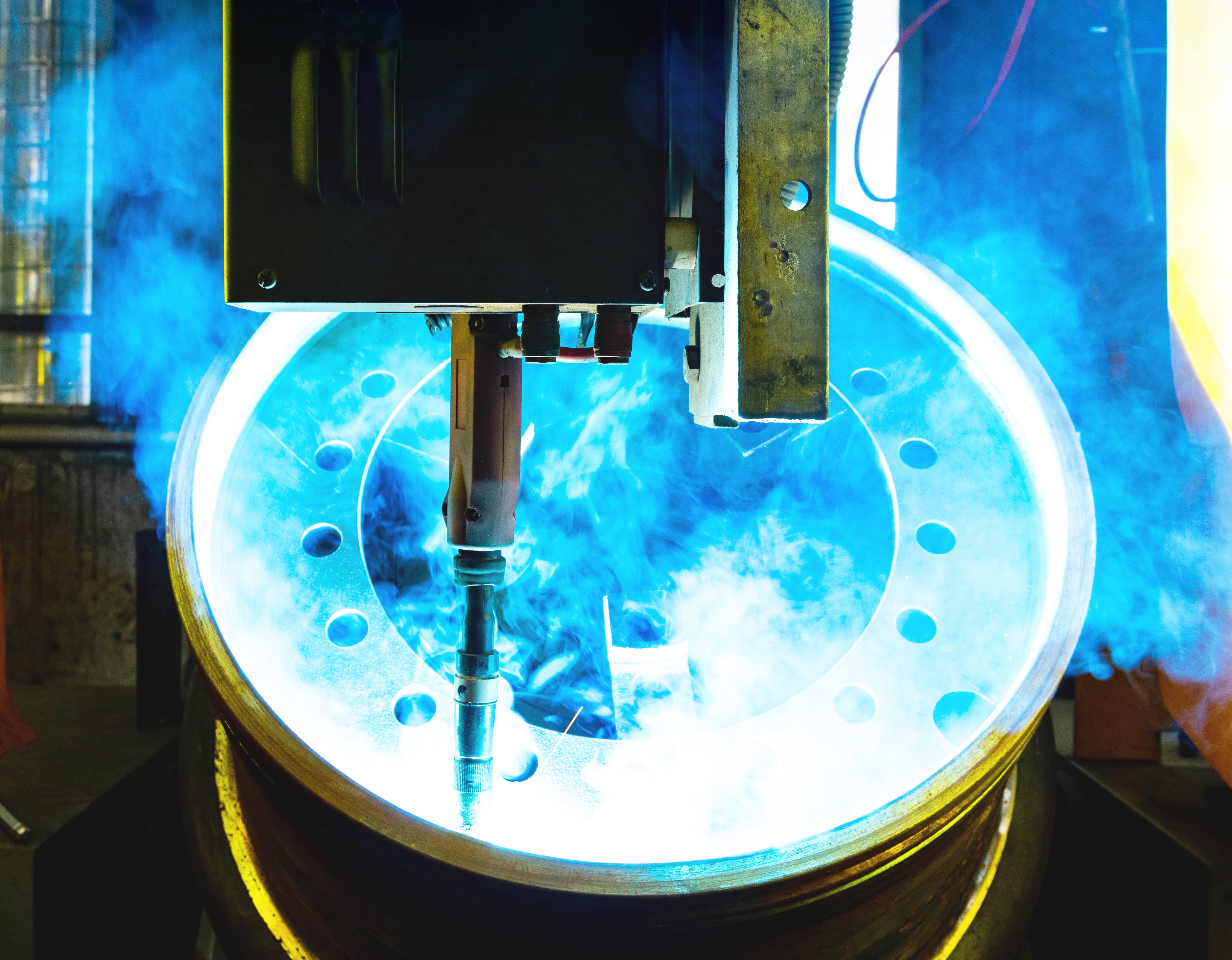

We are one of the few companies in China capable of producing wheel rims across the entire supply chain, from steel to finished product. Our company has its own steel rolling, ring component manufacturing, and welding and painting production lines, which not only ensure product consistency and reliability but also significantly improve production efficiency and cost control. We are an original equipment manufacturer (OEM) wheel rim supplier in China for well-known brands such as Volvo, Caterpillar, Liebherr, and John Deere.

1.Billet

2.Hot Rolling

3. Accessories Production

4. Finished Product Assembly

5.Painting

6. Finished Product

With its leading manufacturing capabilities, rigorous quality control, and global service system, HYWG provides customers with reliable wheel rim solutions. In the future, HYWG will continue to uphold "quality as the foundation and innovation as the driving force" to provide safer and more reliable wheel rim products for the global construction machinery industry.

Post time: Nov-11-2025